Sulfonated poly ether sulfone, and preparation method and application thereof in electrical actuator preparation

A technology of sulfonated polyarylethersulfone and polyarylethersulfone, which is applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of small force output and dependence of artificial muscle materials, etc. Achieve the effect of increasing hydrophilic capacity, improving electrical and mechanical properties, and widening the adjustment range of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Synthesis of polyarylethersulfone

[0045] In a 100mL round bottom flask, add 2.5g of 4,4'-dichlorodiphenylsulfone (DCDPS), 1.9861g of 2,2-bis(4-hydroxyphenyl)propane (bisphenol A, BPA), 15% excess K 2 CO 3 1.381g, solvent N,N-dimethylacetamide (DMAc) 13mL, water agent toluene 6.5mL, then install a condenser with a separator, magnetic stirring, N 2 Under protection, the temperature was slowly raised to 135°C for 3 hours to remove the water generated by the reaction, and then the temperature was raised to 155°C to continue the reaction for 14 hours. After the reaction is over, add a certain amount of DMAc to the flask to dilute the product, then pour it into 100mL of methanol to precipitate the product (polyarylethersulfone, PAES), filter and dry it, and then stir and dissolve the product with 1,2-dichloroethane After 2 hours, it was precipitated in methanol to completely remove impurities such as inorganic salts and small molecules, then washed with wat...

Embodiment 2

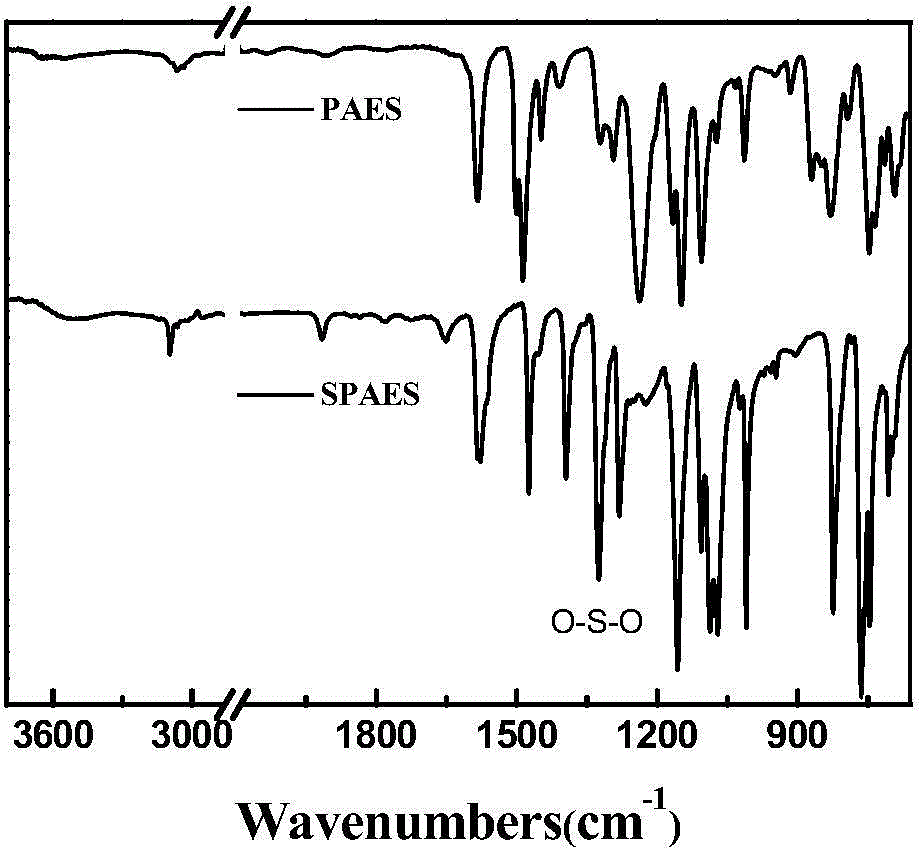

[0046] Example 2: Synthesis of sulfonated polyarylethersulfone

[0047] Weigh 1g of PAES and dissolve in 15mL of 1,2-dichloroethane in a round-bottomed flask connected to a constant pressure dropping funnel, stir magnetically, then measure 100μL of chlorosulfonic acid and dissolve in 10ml of 1,2-dichloro Pour the ethane into the constant pressure funnel, control the flow rate, make the chlorosulfonic acid drop by drop into the PAES solution within 2h, and then continue the reaction for 2h. After the reaction, use a rotary evaporator to distill off the solvent in the reaction system to obtain an amber solid product (sulfonated polyarylethersulfone, SPAES), stir and heat the product in 3% KOH solution to 60°C for 1h, and filter with suction After washing with water, stir and heat to 60° C. in 5% HCl solution, and finally filter and wash with water for several times, then dry. Repeat the above steps to change the dosage of chlorosulfonic acid to 200 μL, 230 μL, 250 μL, 285 μL, a...

Embodiment 3

[0048] Example 3: Synthesis of polyarylethersulfone derivatives (polyarylethersulfone derivatives obtained by condensation of 4,4'-dichlorodiphenylsulfone and bisphenolfluorene)

[0049] Add DCDPS and bisphenol fluorene (BHPF) at a molar ratio of 1:1 to a 100 mL round bottom flask, and an excess of 15% K 2 CO 3 (dried in an oven at 180°C for 24 hours before use), dried dimethyl sulfoxide (DMSO) and water-carrying agent toluene, and then installed a condenser with a water separator, magnetic stirring, N 2 Under protection, the temperature was slowly raised to 135°C for 3 hours to remove the water generated by the reaction, and then the temperature was raised to 170-190°C to continue the reaction for 20 hours. After the reaction is over, add a certain amount of DMSO to the flask to dilute the product polyarylethersulfone derivative (BHPF-PAES), then pour it into 100mL of methanol to precipitate out, filter and dry, and then stir and dissolve the dried product with DMAc for 2h. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com