Preparation method of viscose fiber containing apocynum venetum extract

A technology of apocynum extract and viscose fiber, which is applied in the direction of artificial filaments made of viscose, can solve the problems of poor antibacterial properties of fibers, poor shape retention of fabrics, and weakened antibacterial properties, and achieve strong antibacterial properties and antibacterial agents. Small loss, long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The raw material of embodiment 1 apocynum extract

[0026] The apocynum extract raw material that the present invention selects is the apocynum extract powder, and the requirement of raw material is as follows:

[0027] Loss on drying ≦5.0%, heavy metal content ≦10ppm, total flavonoid glycosides content ≥3.5%, mesh number 80-120.

Embodiment 2

[0029] A preparation method of viscose fiber containing apocynum extract, comprising the following steps:

[0030] (1) Preparation of antibacterial agent solution

[0031] Add Apocynum extract powder to water at a temperature of 25±1°C in an amount of 120g / 1000ml of water, stir well until the powder is completely dissolved to form an antibacterial agent solution, and obtain liquid A.

[0032] (2) Add dispersant

[0033] Add the dispersant to the above liquid A and stir to obtain liquid B.

[0034] (3) Add sodium carboxymethyl cellulose

[0035] Add carboxymethyl cellulose sodium powder into the above liquid B while stirring in a temperature range of 50-60°C in a certain mass ratio to obtain liquid C.

[0036] (4) Blending with spinning dope

[0037] The above liquid C was added to the spinning stock solution at a mass ratio of 15% of the spinning stock solution, stirred and dispersed, and then left to stand for vacuum defoaming to obtain liquid D.

[0038] (5) spinning

...

Embodiment 3

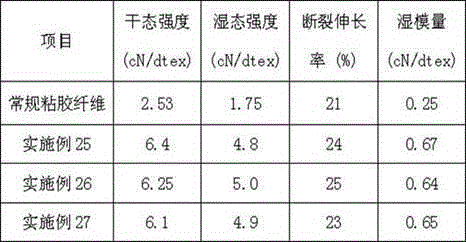

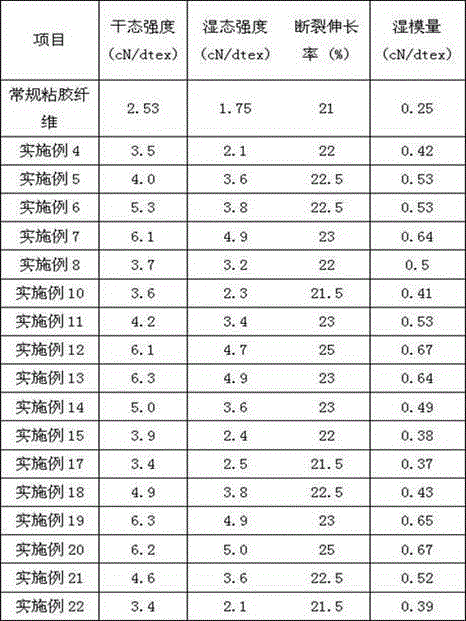

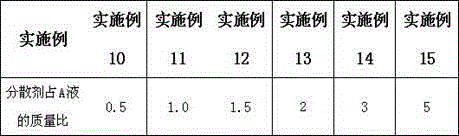

[0042] Example 3 Dispersant Type Single Factor Analysis Experiment

[0043]

[0044] Adopt the dispersant described in embodiment 4-8, the mass ratio that the addition amount of dispersant accounts for A liquid is 1.5%, the mass ratio of sodium carboxymethyl cellulose and B liquid is 1:50, according to implementing 2 Preparation method The viscose fiber containing Apocynum extract was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com