Heat-shrinkable film

A heat-shrinking, weight-saving technology that can be used in packaging recycling, flexible coverings, and other household appliances to solve problems such as surface contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

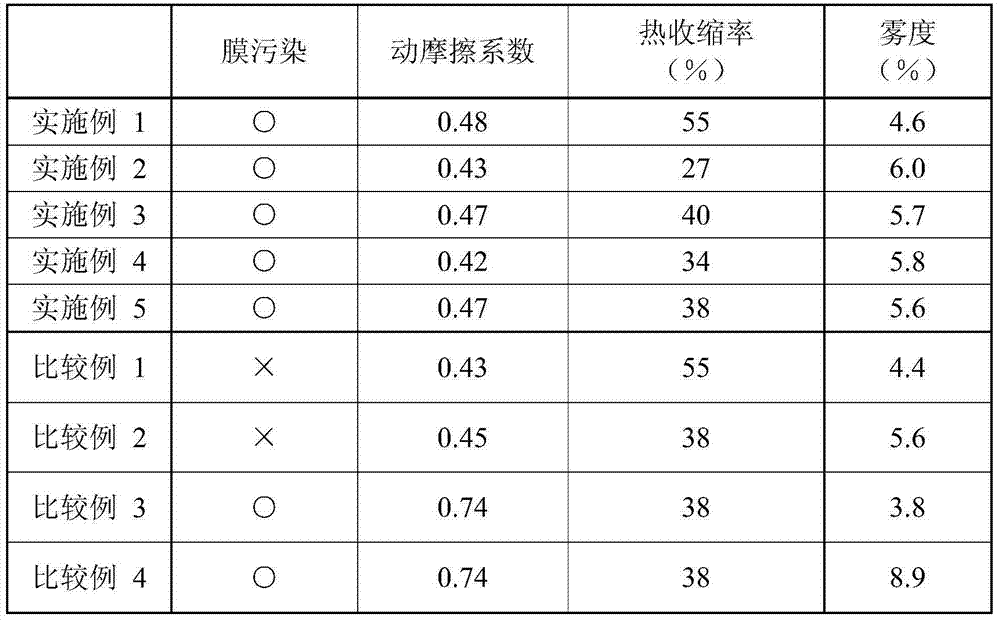

Examples

Embodiment 1

[0075] As the cyclic olefin-based resin, 99.85% by weight of APL8008T (ethylene-tetracyclododecene copolymer, glass transition temperature: 70°C, manufactured by Mitsui Chemicals Co., Ltd.) was used, and 0.15% by weight of organic fine particles was added and mixed therein. Cross-linked styrene microparticles (SX, average particle diameter: 3.5 μm, manufactured by Soken Chemical Co., Ltd.).

[0076] These mixtures were melted at a cylinder temperature of 210° C. using a single-screw extruder, extruded from a T-die, cooled and solidified by a roll cooled to 30° C., and an unstretched sheet was produced. The obtained unstretched sheet was stretched 5 times in the TD direction with a tenter stretching machine at a temperature of 90° C. to form a film with a total thickness of 45 μm.

Embodiment 2

[0078] APL6509T (ethylene-tetracyclododecene copolymer, glass transition temperature: 80° C., manufactured by Mitsui Chemicals Co., Ltd.) 45% by weight, APL8008T (ethylene-tetracyclododecene copolymer) as a cyclic olefin-based resin Mitsui Chemicals Co., Ltd.) 14.9% by weight, linear low-density polyethylene SP2320 (Preman Polymer Co., Ltd.) 40% by weight as vinyl resin, cross-linked polymethacrylic acid as organic fine particles Methyl ester fine particles (MBX Series, average particle diameter 5 μm, manufactured by Sekisui Chemical Industry Co., Ltd.) were mixed at 0.10% by weight.

[0079] Except having used these mixtures, it carried out similarly to Example 1, and obtained the film with the total thickness of 30 micrometers.

Embodiment 3

[0081] As the raw material of the front layer and the back layer, 84.85% by weight of 750R (a hydrogenated product of a norbornene-based ring-opening polymer, manufactured by Japan ZEON Co., Ltd.) as a cyclic olefin resin, and a linear resin as a vinyl resin are used. 15% by weight of low-density polyethylene SP1520 (manufactured by Primeman Polymer Co., Ltd.) and 0.15% by weight of cross-linked polyurethane fine particles (manufactured by Negami Kogyo Co., Ltd., Art Pearl C, average particle size: 6 μm) as organic fine particles were mixed mixture.

[0082] As a raw material for the intermediate layer, 80% by weight of linear low-density polyethylene SP2520 (produced by Primeman Polymer Co., Ltd.) and 750R (hydrogenated norbornene-based ring-opening polymer) as a cyclic olefin resin were used. A mixture obtained by mixing 20% by weight of a product manufactured by Japan ZEON Co., Ltd.

[0083] Using another single-screw extruder, the barrel temperature of the front layer a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com