Long-term environmental protection ship bottom antifouling paint, peelable antifouling paint and ship bottom antifouling treatment method

A technology of antifouling paint and boat bottom, applied in the field of coatings, to achieve the effects of preventing adhesion growth, good adhesion, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

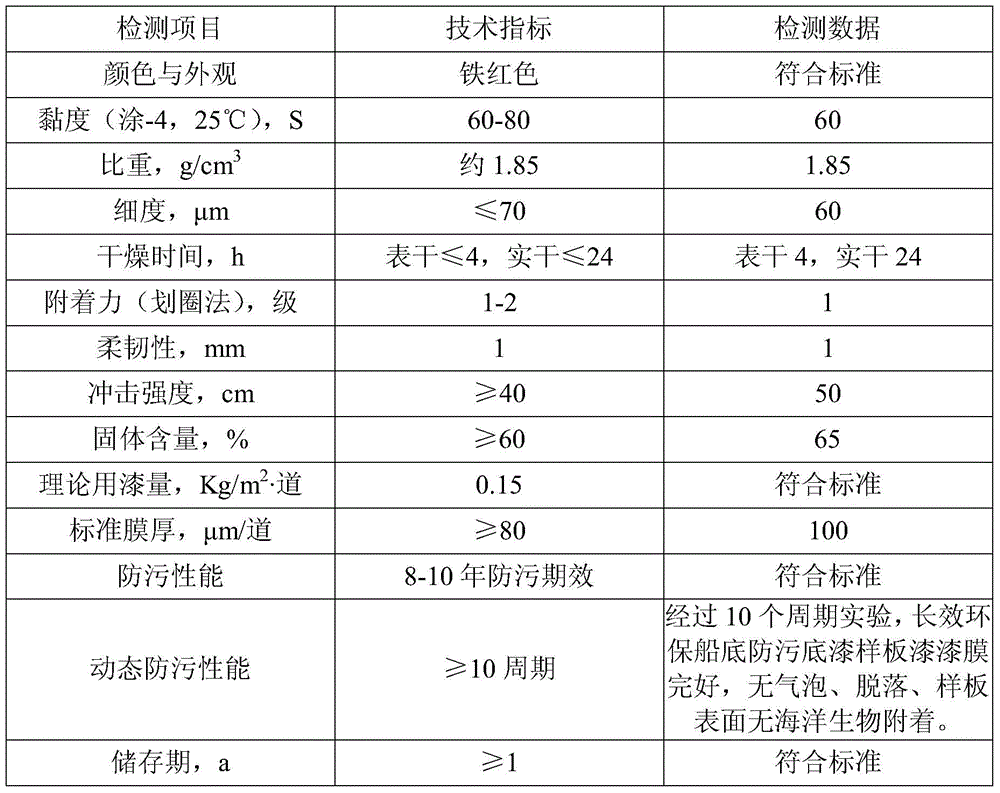

Embodiment 1

[0058] Present embodiment provides a kind of long-acting environmental protection ship bottom antifouling paint, by weight, this long-acting environmental protection ship bottom antifouling primer comprises the following components:

[0059] Acrylic zinc resin 30g;

[0060] Composite organic antifouling agent: flaky cuprous oxide 15g (float rate 80%-85%), superfine cuprous oxide 15g, copper pyrithione 5g, 2-tert-butylamino-4-cyclopropylamino-6- Methylthio-S-triazine 4g;

[0061] Pigment: iron red 6g, zinc oxide 12g;

[0062] Filler: barite 15g;

[0063] Mixed solvent: xylene 20g, trimethylbenzene 3g;

[0064] Dispersant: Propyl Methoxy Acetate 0.2g;

[0065] Anti-sedimentation agent: organic bentonite 2g.

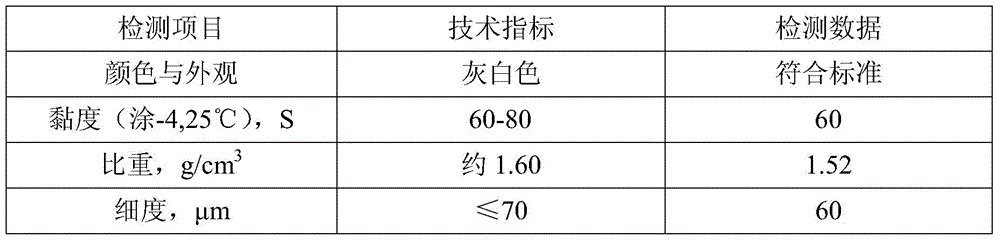

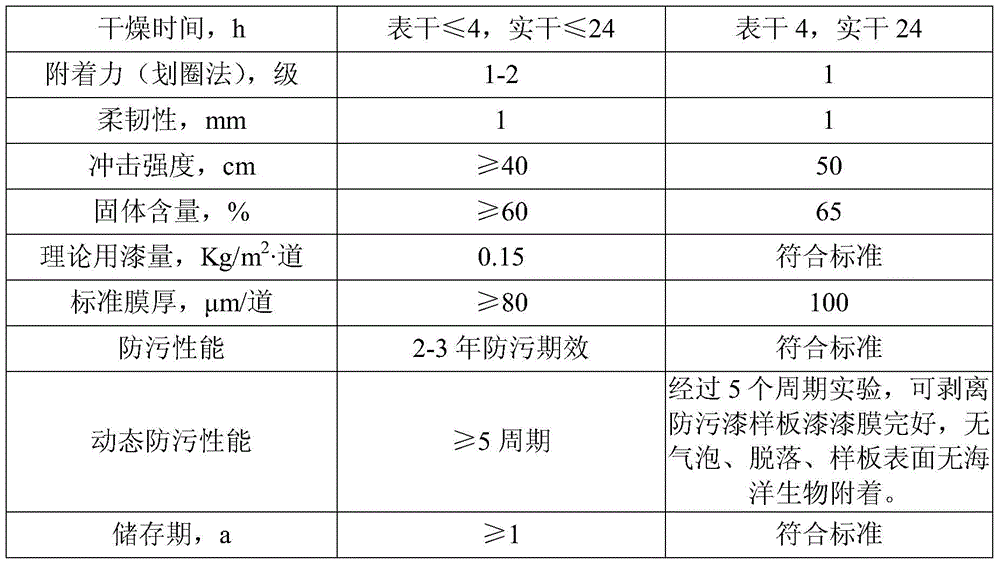

[0066] The present embodiment also provides a strippable antifouling paint, in parts by weight, the strippable antifouling paint comprises the following components:

[0067] Perchlorethylene resin 32g;

[0068] Superfine cuprous oxide 15g, copper pyrithione 3g;

[0...

Embodiment 2

[0087] The present embodiment provides a kind of long-acting environmental protection ship bottom antifouling treatment method, it uses the long-acting environmental protection ship bottom antifouling paint of embodiment 1 and peelable antifouling paint, comprises the steps:

[0088] Apply long-lasting environmental protection ship bottom antifouling paint (4 coats) on the bottom of the ship, the total thickness of the coating film is 380-400μm, forming an internal antifouling coating;

[0089] Then apply peelable antifouling paint (2 coats), the total thickness of the coating film is 20-30μm, forming a middle peelable layer;

[0090] Then recoat the long-term environmental protection ship bottom antifouling paint (4 coats), the total thickness of the coating film is 380-400 μm, and form the external antifouling coating.

[0091] After 4-5 years, the remaining external anti-fouling coating and the middle peelable layer are removed by washing, so that the internal anti-fouling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com