Method for using waste oil and grease as raw material to prepare fatty acid methyl ester

A technology of fatty acid methyl ester and waste oil, which is applied in fatty acid esterification, fuel, petroleum industry and other directions, can solve the problem of cost competition in the preparation of immobilized lipase catalyst, and achieve the effects of lowering temperature, preventing saponification and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

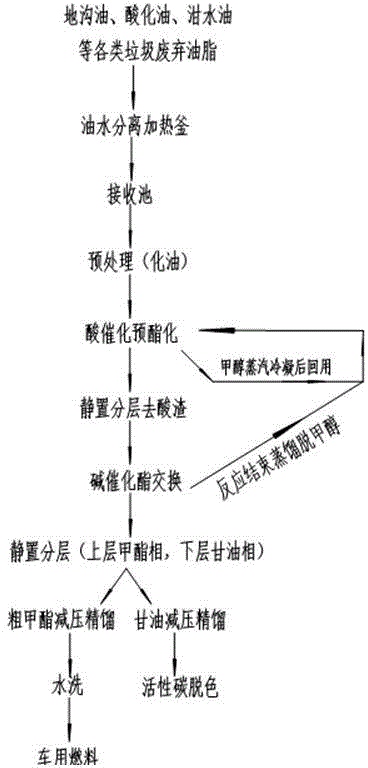

Method used

Image

Examples

Embodiment 1

[0072] 1. Raw material pretreatment: send the raw material oil with an acid value of 102mgKOH / g into the carburetor pool, and raise the temperature of the carburetor room to 60-80°C for 1 hour through the steam sent by the boiler system, and send the heated material through the feeding pump Put it into the separation tower and let it rest for 8 hours to drain the water impurities, and the water impurities will be reduced to below 3%, and the static temperature is kept at 40°C.

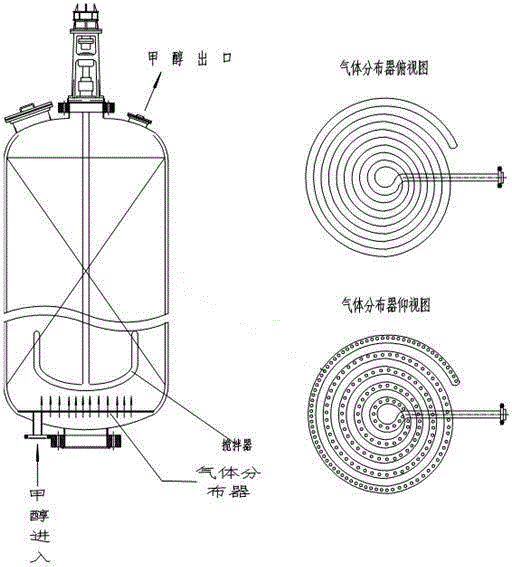

[0073] 2. Pre-esterification: Send 4500L of static oil into the pre-esterification reaction kettle through the pre-esterification feed pump, start stirring, and heat up while feeding. When feeding, when the liquid surface submerges the first stirring fin, start stirring, and open the steam valve of the pre-esterification kettle, and heat up while feeding, and the steam pressure is controlled at 0.4MPa. ℃, feed crude methanol gas, the flow rate is not lower than 450L / h. After passing methanol for 5 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com