Method for preparing zirconium dioxide permeation layer by zirconium or zirconium alloy surface ion oxygen permeation

A technology of ionic oxygen infiltration and zirconium dioxide, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc. , low hardness of zirconium and zirconium alloys, etc., to achieve the effect of improving surface hardness and corrosion resistance, simple equipment and fast growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] This embodiment includes the following steps:

[0017] Step 1: Grinding the surface of the zirconium alloy, then ultrasonically cleaning the polished zirconium alloy, washing with water, and then drying; the zirconium alloy is a Zr-3 alloy, and the ultrasonic cleaning time is 30 minutes;

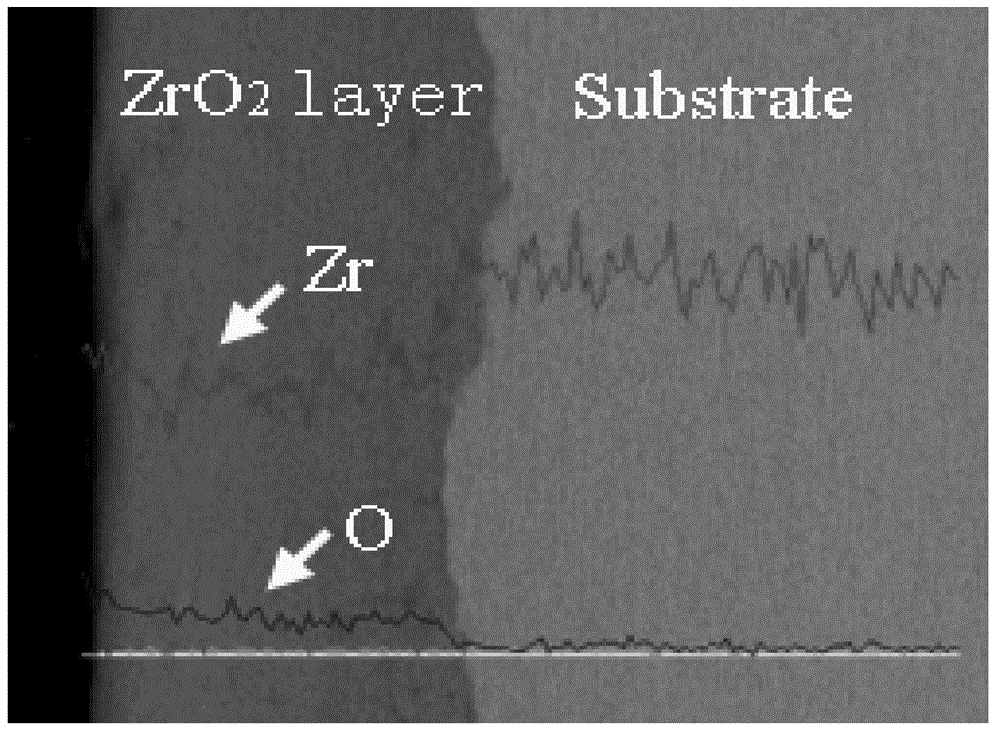

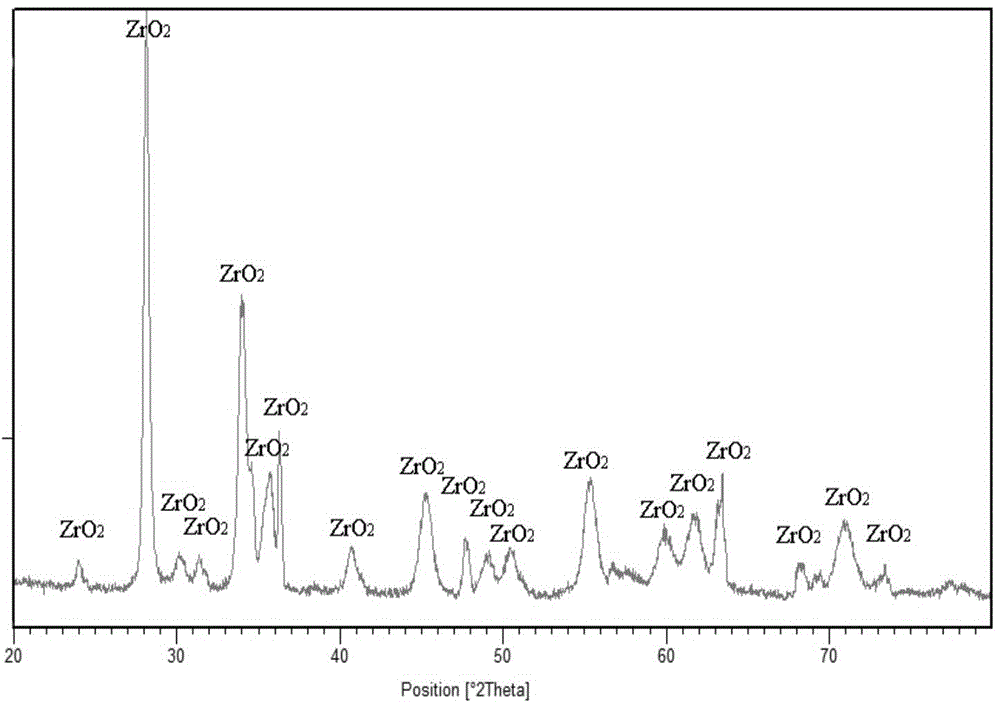

[0018] Step 2. Place the dried zirconium or zirconium alloy in the step 1 in the ion nitriding furnace, vacuumize until the pressure in the furnace is not greater than 10Pa, then feed argon gas into the vacuumized ion nitriding furnace, Under the condition that the air pressure in the furnace is not lower than 20Pa, carry out ion bombardment cleaning on the surface of zirconium or zirconium alloy. The surface of the zirconium alloy after cleaning is subjected to ion oxygen infiltration treatment, and after being cooled to room temperature with the furnace, a zirconium dioxide infiltration layer is obtained on the surface of the zirconium alloy; the time for the ion bombardment cleanin...

Embodiment 2

[0021] This embodiment includes the following steps:

[0022] Step 1. Polish the zirconium surface, then ultrasonically clean the polished zirconium, wash with water and then dry; the zirconium is pure zirconium with a mass purity of not less than 99%, and the ultrasonic cleaning time is 35 minutes;

[0023] Step 2. Place the dried zirconium or zirconium alloy in the step 1 in the ion nitriding furnace, vacuumize until the pressure in the furnace is not greater than 10Pa, then feed argon gas into the vacuumized ion nitriding furnace, Under the condition that the pressure in the furnace is not lower than 20Pa, carry out ion bombardment cleaning on the surface of zirconium or zirconium alloy. The cleaned zirconium surface is subjected to ion oxygen permeation treatment, and after being cooled to room temperature with the furnace, a zirconium dioxide infiltrated layer is obtained on the zirconium surface; the time for the ion bombardment cleaning is 40 minutes, and the time for t...

Embodiment 3

[0026] This embodiment includes the following steps:

[0027] Step 1: Grinding the surface of the zirconium alloy, then ultrasonically cleaning the polished zirconium alloy, washing with water, and then drying; the zirconium alloy is a Zr-1 alloy, and the ultrasonic cleaning time is 40 minutes;

[0028] Step 2. Place the dried zirconium or zirconium alloy in the step 1 in the ion nitriding furnace, vacuumize until the pressure in the furnace is not greater than 10Pa, then feed argon gas into the vacuumized ion nitriding furnace, Under the condition that the pressure in the furnace is not lower than 20Pa, carry out ion bombardment cleaning on the surface of zirconium or zirconium alloy. The surface of the zirconium alloy after cleaning is subjected to ion oxygen infiltration treatment, and after being cooled to room temperature with the furnace, a zirconium dioxide infiltration layer is obtained on the surface of the zirconium alloy; the time for the ion bombardment cleaning is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com