Preparation method of in-plane anisotropy Bi-substituted garnet magneto-optic single crystal thin film

An anisotropic, single-crystal thin film technology, applied in the field of materials, can solve the problems of high conversion efficiency, large bandwidth, and impossibility, and achieve the effect of improving film quality, high stability, and good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

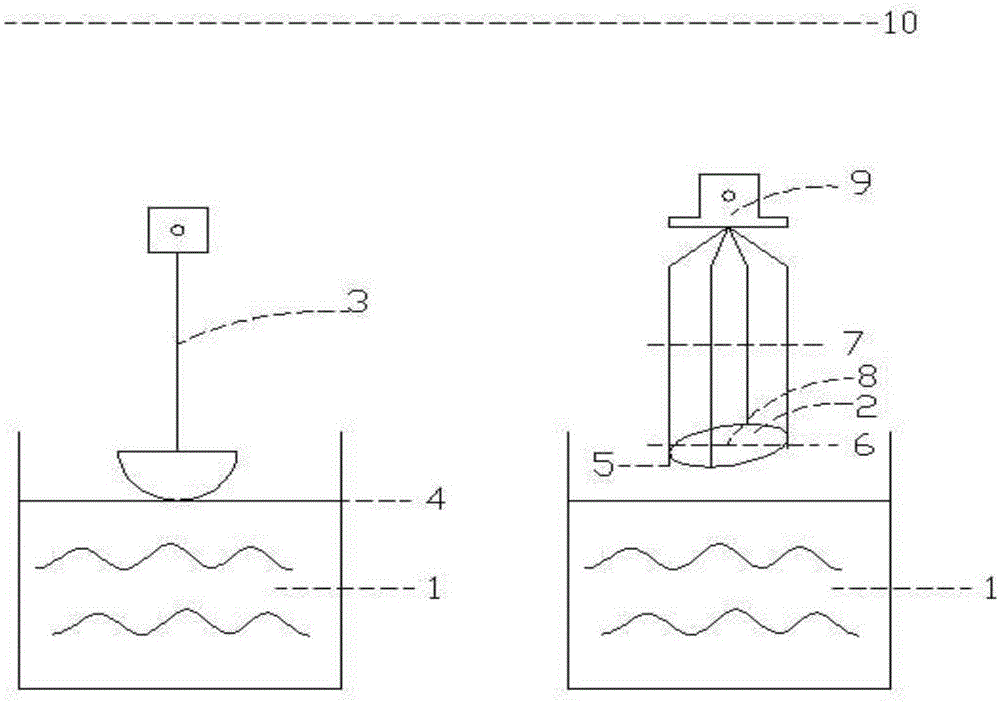

[0022] A preparation method of an in-plane anisotropic Bi-generation garnet magneto-optical single crystal film, comprising the following steps:

[0023] Step 1. Formula, ingredients:

[0024] Formula is Bi x Lu 3-x IG, according to the best matching relationship, take x as 0.9; this implementation example uses lead-free epitaxy, with Lu2O3, Bi2O3, Fe2O3 as raw materials, that is, melt, Bi2O3 as flux, CaO as additive, R0=1, R1= 0.1294, R2=0.1751, R3=0.01; the ratio of each component is determined according to the ratio, the amount of each raw material is determined according to the weight specific gravity and the total quality, the specific gravity of Bi2O3, Lu2O3, Fe2O3, CaO is 92.195%, 1.898%, 5.886 %, 0.021%, the total amount is 6000g; because the volume of the powder is larger than the volume of the melt and the size of the crucible is fixed, the material should be added to the crucible several times, and the method of adding material, melting, cooling, and refilling is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com