Method for preparing silicon nanostructured material based on external electric field

A technology of structural materials and external electric field, applied in the direction of nanotechnology, chemical instruments and methods, crystal growth, etc., can solve the problems of complicated operation and difficult control, and achieve the effect of simple and easy method, which is conducive to large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

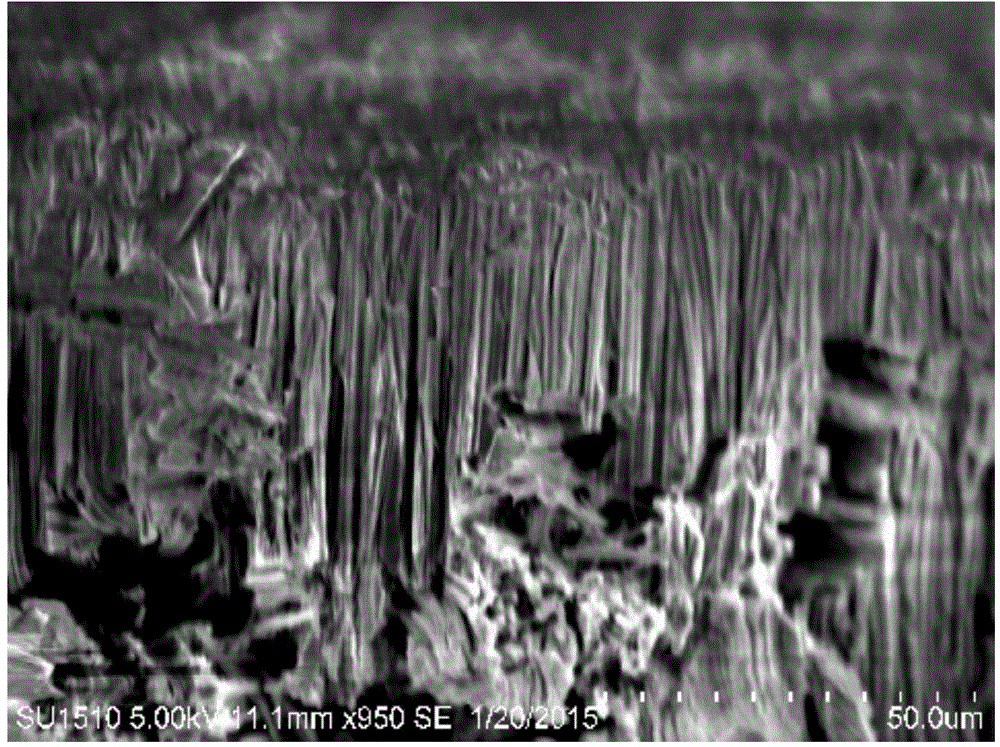

Image

Examples

Embodiment 1

[0019] Put the clean monocrystalline silicon (100) into the mixed solution of silver nitrate and hydrofluoric acid to deposit a layer of silver film on the surface of the silicon wafer, and then quickly put it into the corrosion solution. The corrosion solution is filled in the container, and the two sides of the container are fixed. A pair of graphite electrodes, the graphite electrodes are immersed in the corrosion solution. The proportion of components of the corrosion solution is hydrofluoric acid: hydrogen peroxide at a volume ratio of 12:1, the mass concentration of hydrofluoric acid is 40%, and the mass concentration of hydrogen peroxide is 30%. Turn on the power supply of the graphite electrode, keep the voltage at 1.4mV, corrode at 15°C-25°C for 90min, take it out, wash and dry it, and obtain the silicon nanowire structure.

Embodiment 2

[0021] Put the clean monocrystalline silicon (110) into the mixed solution of silver nitrate and hydrofluoric acid to deposit a layer of silver film on the surface of the silicon wafer, and then quickly put it into the corrosion solution. The corrosion solution is filled in the container, and the two sides of the container are fixed. A pair of graphite electrodes, the graphite electrodes are immersed in the corrosion solution. The proportion of components of the corrosion solution is hydrofluoric acid: hydrogen peroxide at a volume ratio of 12:1, the mass concentration of hydrofluoric acid is 40%, and the mass concentration of hydrogen peroxide is 30%. Turn on the graphite electrode power supply, keep the voltage at 5mV, corrode at 15°C-25°C for 90min, take it out, wash and dry it, and obtain a silicon nanowire structure.

Embodiment 3

[0023] Put the clean monocrystalline silicon (111) into the mixed solution of silver nitrate and hydrofluoric acid to deposit a layer of silver film on the surface of the silicon wafer, and then quickly put it into the corrosion solution. The corrosion solution is filled in the container, and the two sides of the container are fixed. A pair of graphite electrodes, the graphite electrodes are immersed in the corrosion solution. The proportion of components of the corrosion solution is hydrofluoric acid: hydrogen peroxide at a volume ratio of 12:1, the mass concentration of hydrofluoric acid is 40%, and the mass concentration of hydrogen peroxide is 30%. Turn on the power supply of the graphite electrode, keep the voltage at 8mV, corrode at 15°C-25°C for 90min, take it out, wash and dry it, and obtain a silicon nanowire structure.

[0024] The invention belongs to the technical field of preparing silicon nanostructure materials, and in particular relates to a method for preparin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com