Bidirectional waste heat recovery device for outdoor air pretreatment of air conditioner

A waste heat recovery device and pretreatment technology, applied in the field of air conditioning engineering, can solve the problems of complex system, power consumption, air quality decline, etc., and achieve the effects of high energy recovery rate, avoiding fresh air pollution, and reducing structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives and technical solutions of the embodiments of the present invention clearer, the technical solutions of the embodiments of the present invention will be further described clearly and completely in conjunction with the accompanying drawings of the embodiments of the present invention.

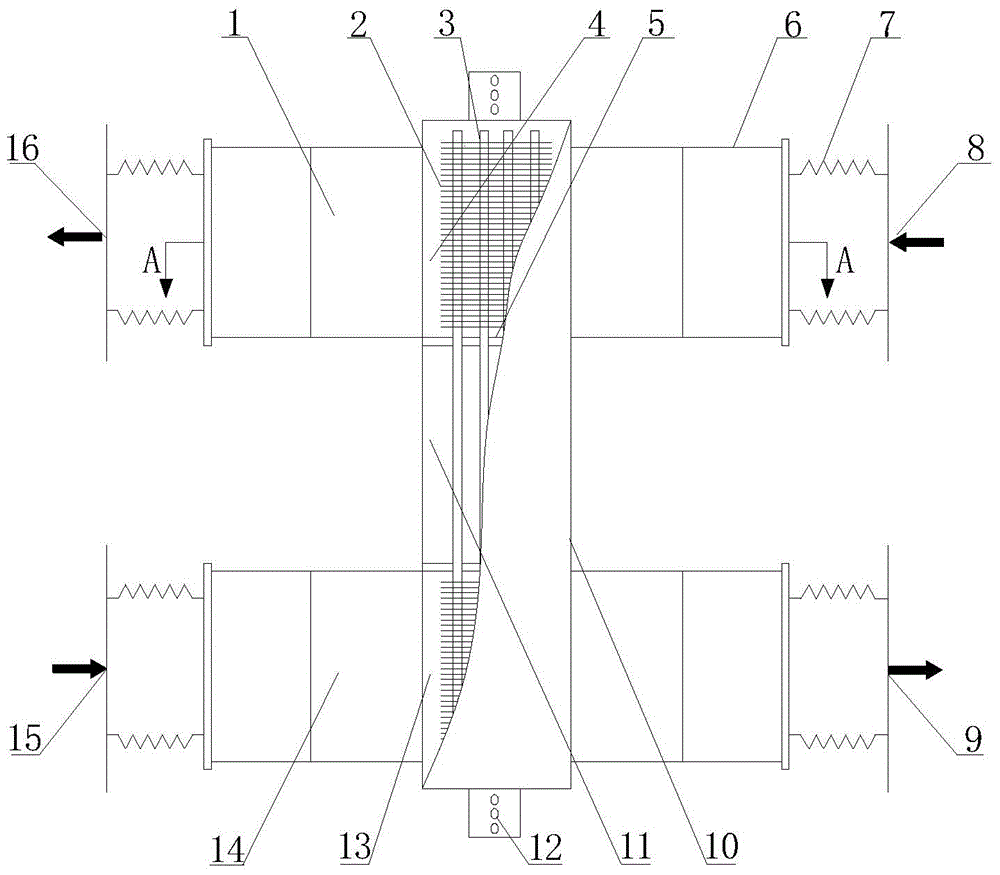

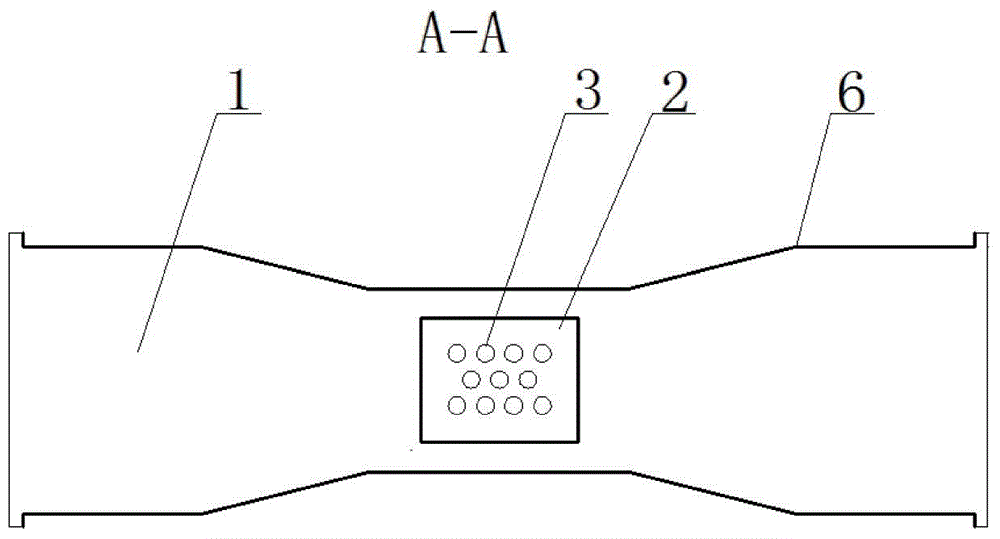

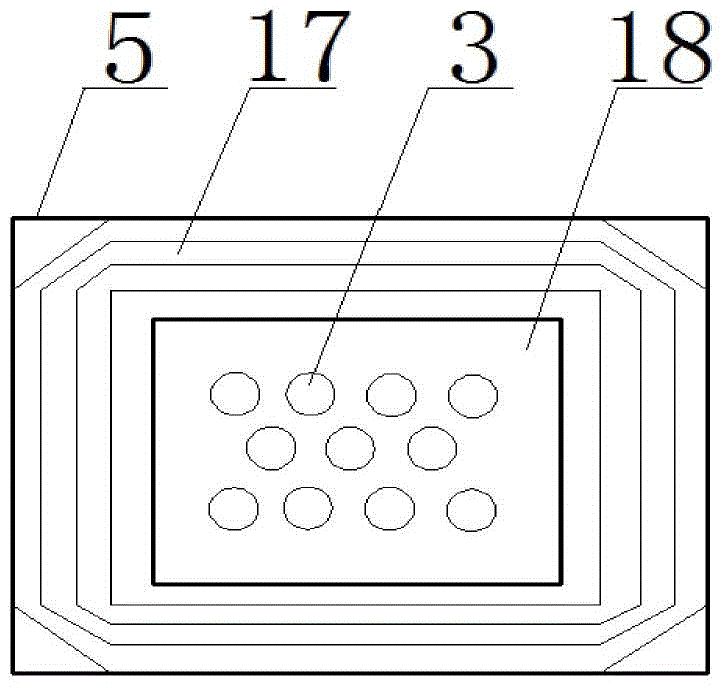

[0025] As attached Figure 1 to 4 Shown here is a two-way waste heat recovery device for air conditioning fresh air pretreatment of the present invention, on the walls of the corresponding air duct shell 6 of the exhaust air heat exchange duct 1 and the fresh air heat exchange duct 14 arranged in parallel and isolated A through hole with a coaxial line is opened, and an open sealing partition 5 is installed in the through hole, and a universal telescopic structure 17 and an internal fixed partition 18 are sequentially installed in the hole of the sealing partition 5 from the outside to the inside. A total of 11 heat pipes 3 arranged in an inverted and authenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com