Pradaxa-containing microemulsion preparation

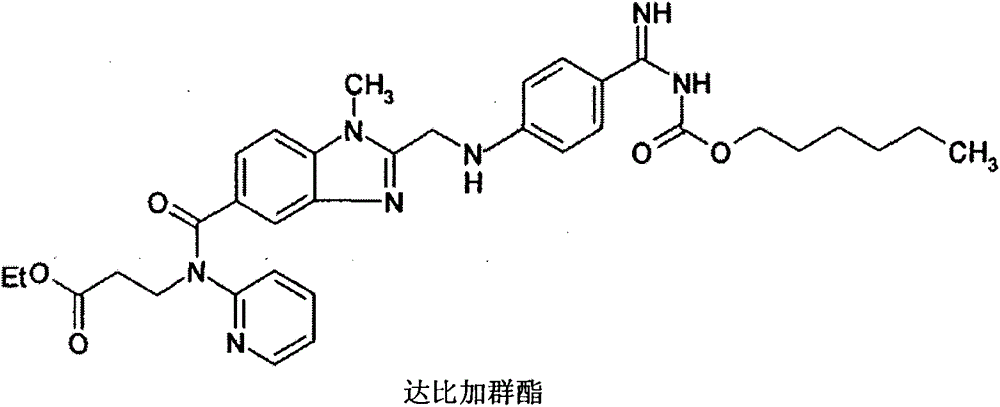

A dabigatran etexilate and microemulsion technology, applied in the field of medicine, can solve the problems of low bioavailability, complex process, poor dissolution of dabigatran etexilate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

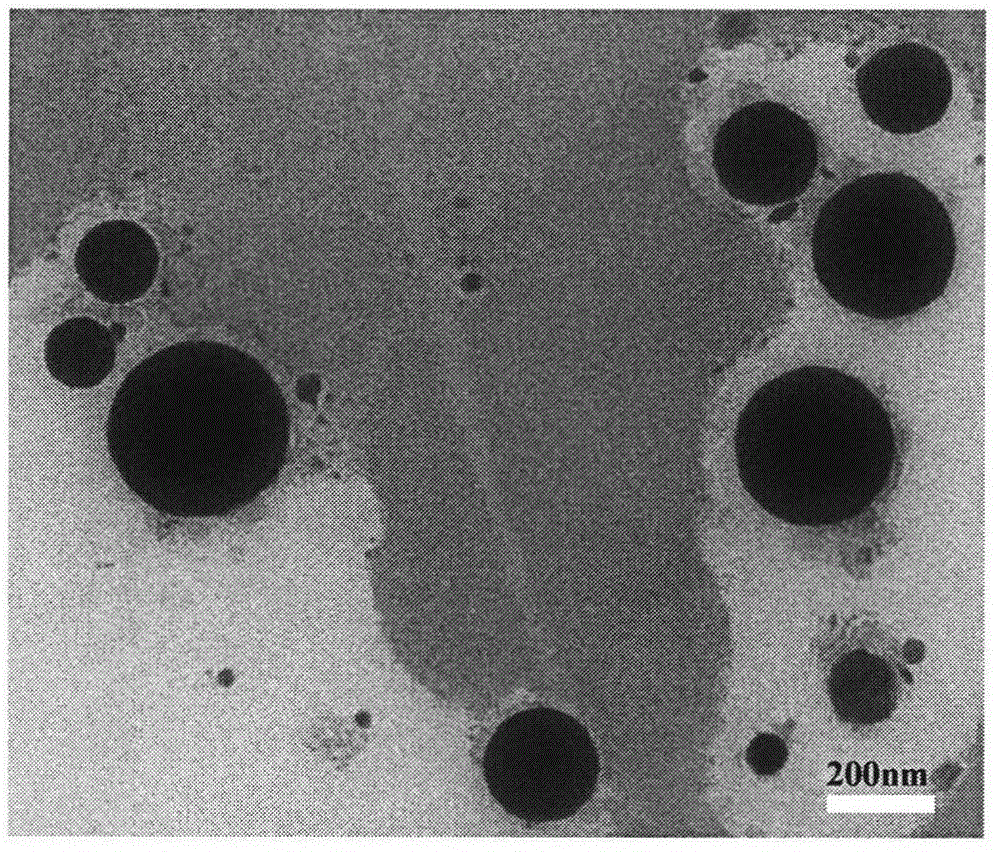

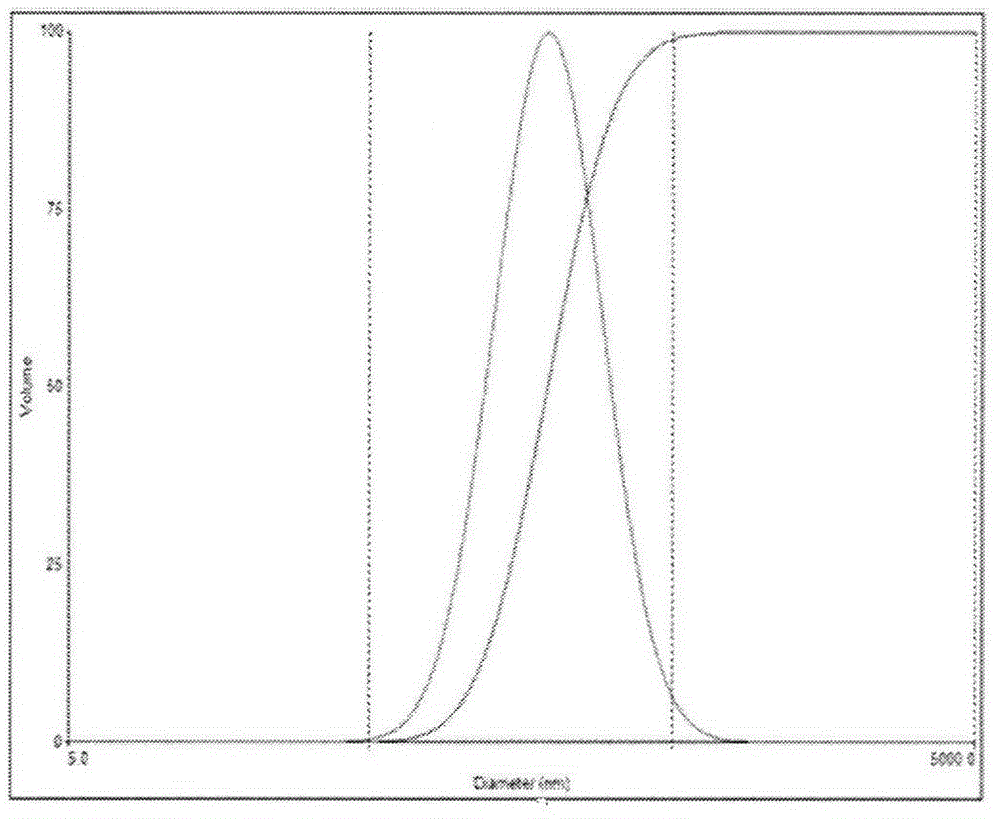

[0054] Embodiment 1 A kind of dabigatran etexilate microemulsion preparation, each raw material proportioning of this microemulsion preparation is as follows:

[0055] Specifications: 100ml

[0056]

[0057] Preparation process: Accurately weigh 0.25 g of dabigatran etexilate according to the prescription ratio, dissolve it in propylene glycol, add medium-carbon chain triglycerides, polyoxyethylene hydrogenated castor oil, and oleic acid, and stir continuously at room temperature until dissolved and mixed evenly. Obtain the drug-containing oil phase of dabigatran etexilate; dissolve poloxamer 188 and povidone K30 in deionized water, and mix uniformly to obtain the water phase; heat the oil phase and the water phase to 60° C. Slowly drop the oil phase into the water phase, stir at high speed for 8 minutes, continue to add sorbic acid, stevioside, and aspartame, and finally add deionized water to make the volume to 100ml to obtain dabigatran etexilate microemulsion.

Embodiment 2

[0058] Embodiment 2 A kind of dabigatran etexilate microemulsion preparation, each raw material proportioning of this microemulsion preparation is as follows:

[0059] Specifications: 100ml

[0060]

[0061] Preparation process: Accurately weigh 0.25 g of dabigatran etexilate according to the prescription ratio, dissolve it in propylene glycol, add medium-carbon chain triglycerides, castor oil, polyoxyethylene hydrogenated castor oil, and oleic acid, and stir continuously at room temperature until dissolved and Mix well to obtain the drug-containing oil phase of dabigatran etexilate; dissolve poloxamer 188 and povidone K30 in deionized water, and mix uniformly to obtain the water phase; heat the oil phase and the water phase to 60°C respectively, Under magnetic stirring, the oil phase was slowly dropped into the water phase, stirred at a high speed for 8 minutes, continued to add sorbic acid, stevioside, and aspartame, and finally added deionized water to settle to 100ml to...

Embodiment 3

[0062] Embodiment 3 A kind of dabigatran etexilate microemulsion preparation, each raw material proportioning of this microemulsion preparation is as follows:

[0063] Specifications: 100ml

[0064]

[0065] Preparation process: Accurately weigh 0.25 g of dabigatran etexilate according to the prescription ratio, dissolve it in propylene glycol, add medium-carbon chain triglycerides, egg yolk lecithin, and oleic acid, and stir continuously at room temperature until dissolved and mixed to obtain Dabigatran etexilate Gatran etexilate containing drug oil phase; Dissolve Poloxamer 188 and Povidone K30 in deionized water, mix well to obtain water phase; heat oil phase and water phase to 60°C respectively, under magnetic stirring, The oil phase was slowly dropped into the water phase, stirred at high speed for 8 minutes, continued to add sorbic acid, stevioside, and aspartame, and finally added deionized water to make the volume to 100ml, and obtained dabigatran etexilate microemu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com