A support material and preparation method for electromagnetic compatibility and wireless product testing

A support material, electromagnetic compatibility technology, applied in the coating and other directions, can solve the problems of unsatisfactory, poor mechanical properties and temperature resistance, not meeting the standards and specifications of electromagnetic compatibility and wireless products, and the method is simple and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The raw materials including polyisocyanate, polyether polyol, small molecular polyol and water are prepared into two kinds of prepolymers. The main components of these two prepolymers are different. The main component of one is polyisocyanate, and the main component of the other is polyether polyol, small molecule polyol, and water. Once the two prepolymers are combined, a series of chemical and physical reactions will occur. The ratio of prepolymer is controlled between 1:1 and 1:3. The two prepolymers are placed in two different containers to prevent premature reaction. After the two prepolymers are filled into the same container, they are fully stirred at high speed and quickly filled into the prepared mold. The ratio and total weight of the two prepolymers charged into the mold will affect the density and hardness of the final formed material. The density of the final material should be controlled between 30 kg per cubic meter and 600 kg per cubic meter.

[0019...

PUM

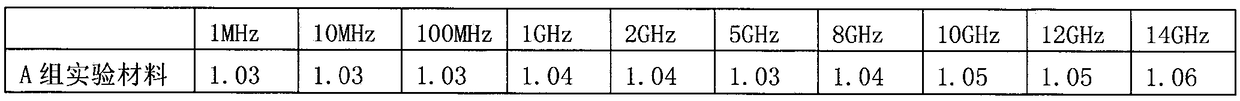

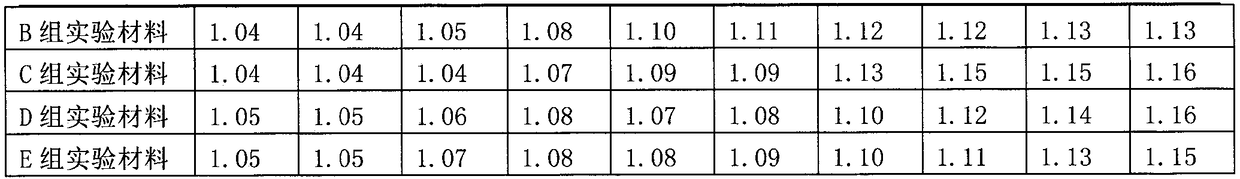

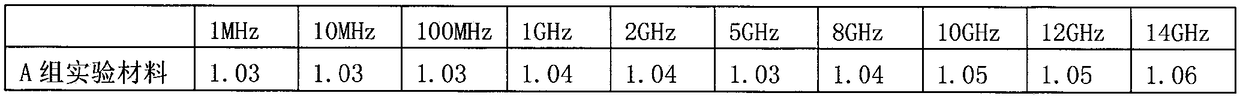

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com