A method for preparing soluble polyimide by induction heating of magnetic particles

A soluble polyimide and induction heating technology, applied in the field of preparation of soluble polyimide, can solve the problems of long imidization cycle, unstable resin performance, slow heating and heating rate, etc., to avoid temperature instability, Improved stability and consistent response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

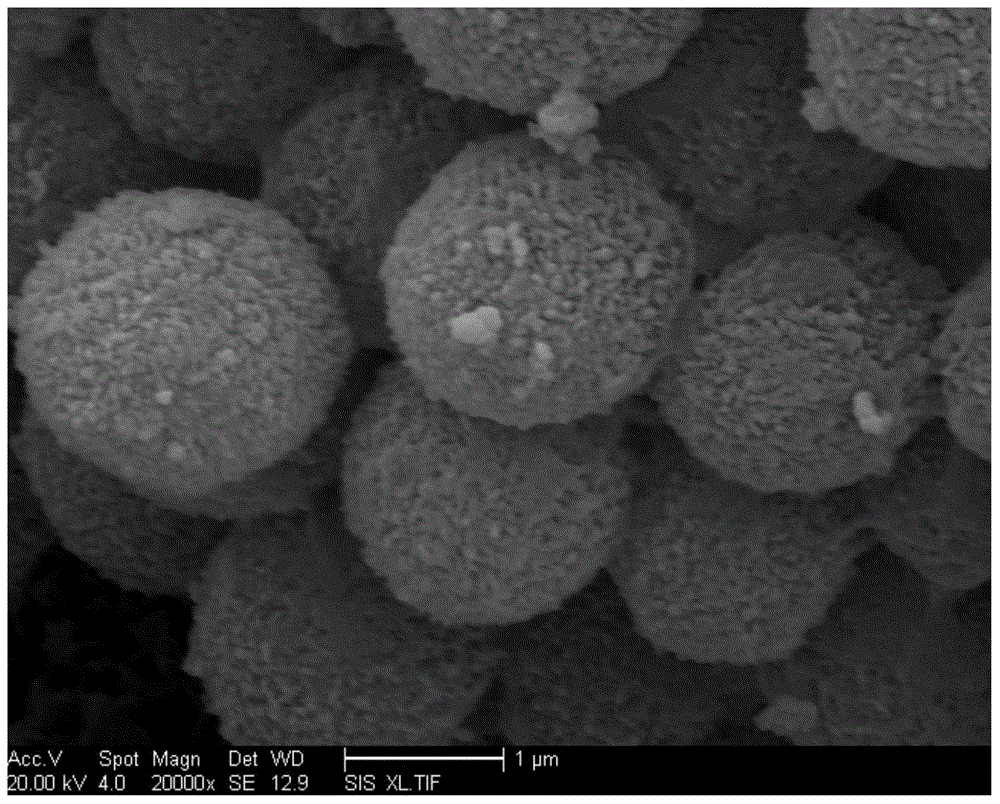

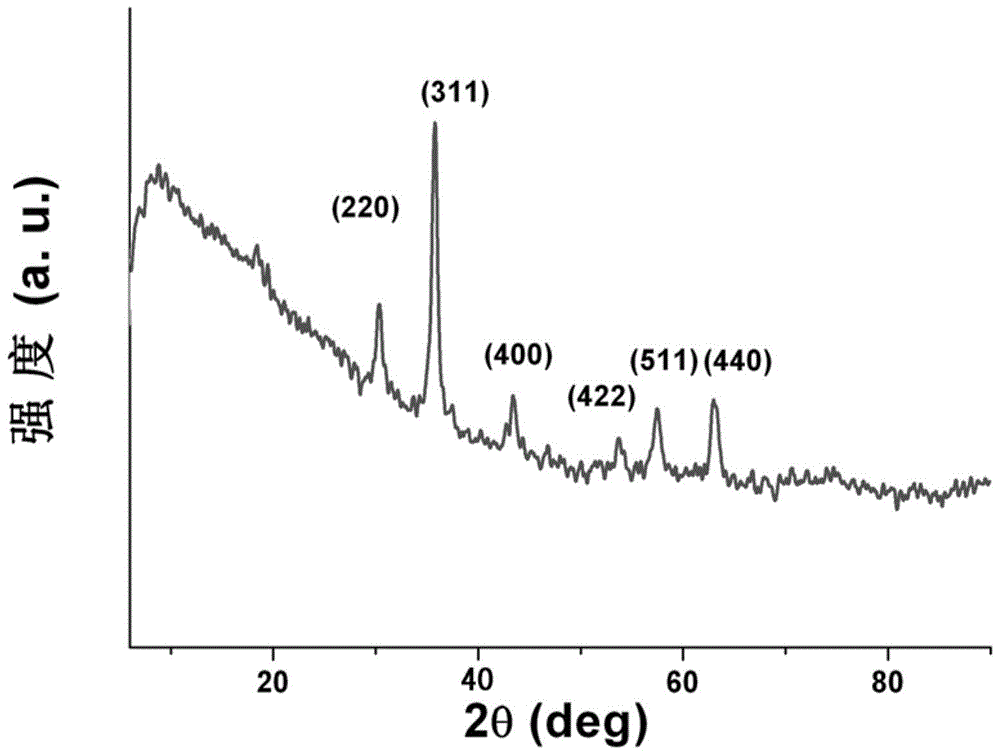

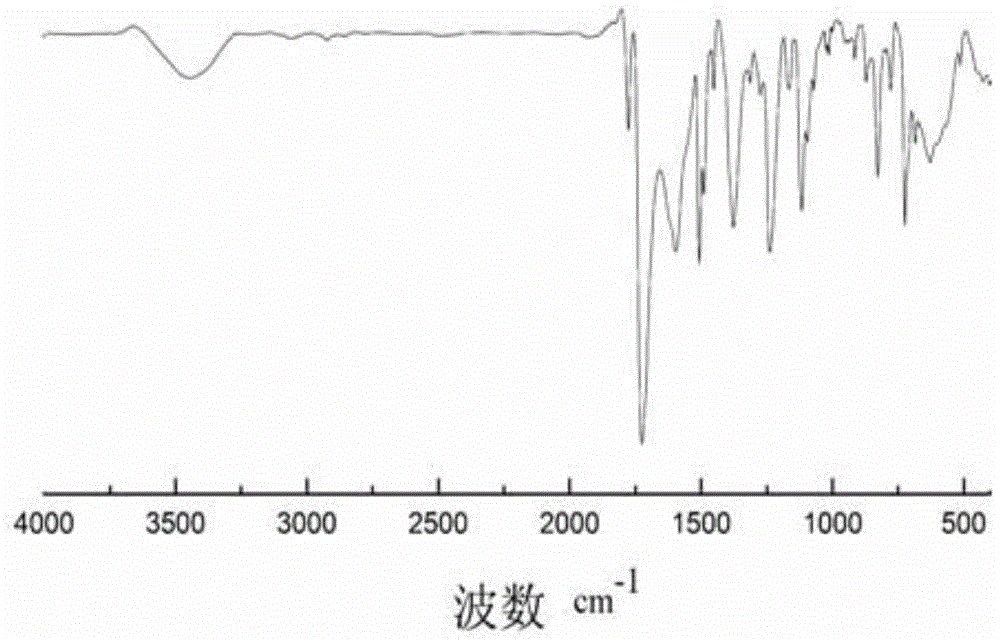

[0038] Specific implementation mode one: combine Figure 5 Specifically illustrate this embodiment, a method for preparing soluble polyimide by induction heating of magnetic particles described in this embodiment is carried out according to the following steps:

[0039] 1. ①. Under nitrogen atmosphere, room temperature and stirring conditions, add high boiling point polar solvent and aromatic diamine into the three-necked flask, react for 0.5h~1h, then add aromatic dianhydride into the three-necked flask, react for 1h~ 5h, then add tertiary amine into the three-necked flask, react for 2h~3h, stop stirring to get the reaction solution, under stirring condition, drop the reaction solution into acetone at the speed of 2mL / s~10mL / s, the dropwise addition is completed Afterwards, continue to stir for 1h-6h, then stand still for 3 days to 10 days to obtain a standing liquid containing filaments, take out the filaments in the standing liquid containing filaments, Dry the filaments i...

specific Embodiment approach 2

[0063] Embodiment 2: This embodiment differs from Embodiment 1 in that: the permanent magnet described in Step 4 has a magnetic induction of 0.1 tesla to 1.5 tesla. Others are the same as in the second embodiment.

specific Embodiment approach 3

[0064] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the water-carrying agent described in step 2 is one of toluene and xylene or a mixture of two of them. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com