Asphalt temperature performance reinforcing agent, production method and applications thereof

A technology of temperature performance and reinforcing agent, which is applied to building thermal insulation materials, building components, buildings, etc., can solve the problems of insufficient high temperature stability of asphalt, and achieve the effects of maintaining good low temperature performance of pavement, flexible technology and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

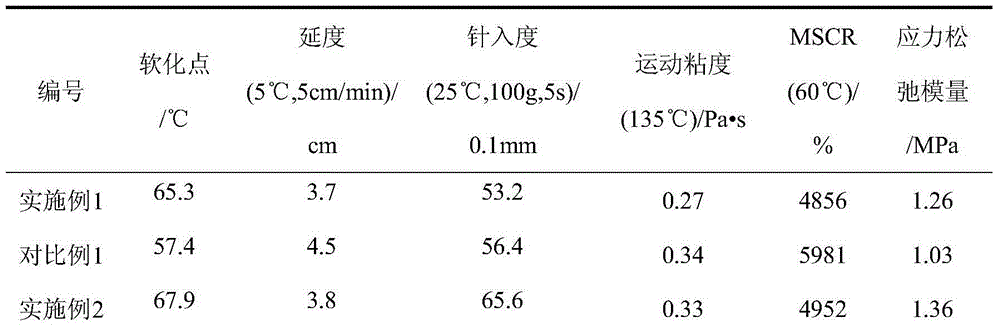

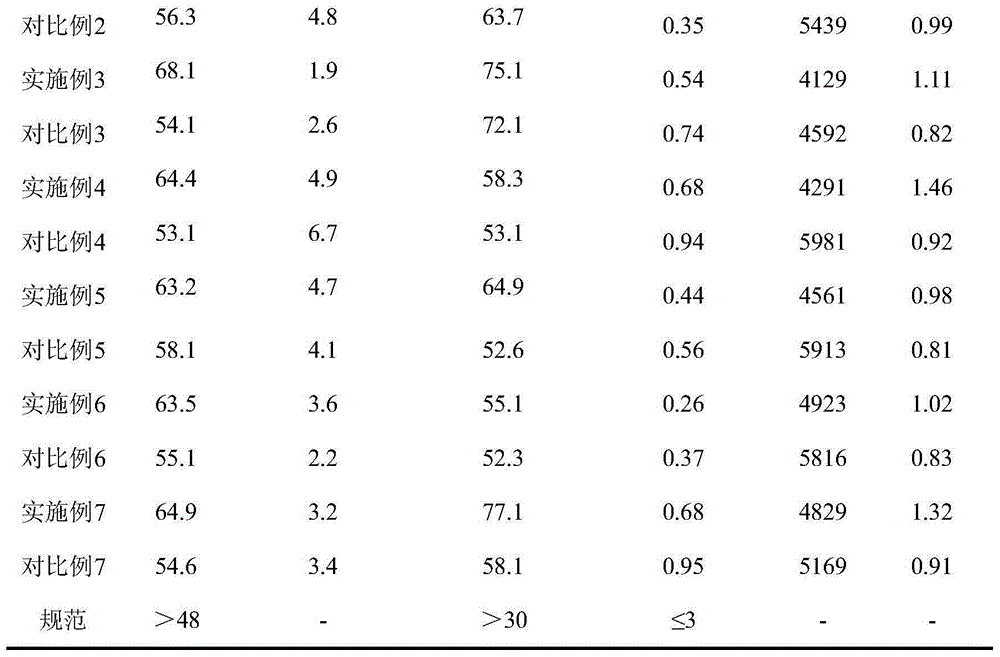

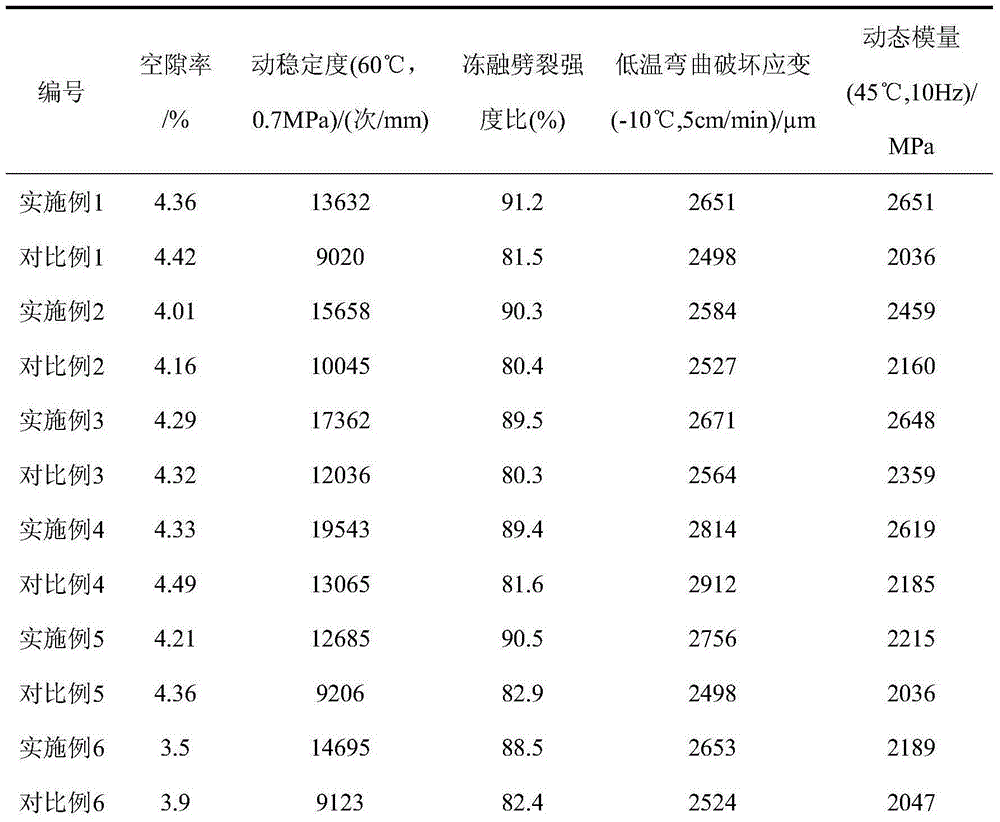

Examples

Embodiment 1

[0052] An asphalt temperature performance enhancer is composed of the following components according to the total weight percentage:

[0053] Vegetable shed film with a PE content of not less than 80% accounts for 38%, PE-based diatomite masterbatch accounts for 12%, rock asphalt accounts for 25%, 80 mesh meridian waste tire rubber powder accounts for 18%, and ricinoleic acid Cadmium stabilizer 1.7%, diphenylamine antioxidant 2.8%, liquid paraffin 1%, PE-based masterbatch 1.5%. A total of 8 kinds of ingredients are mixed in the pre-mixer at room temperature at a stirring speed of 2000r / min for about 5-15 minutes until they are evenly mixed, transported to the hopper of the extrusion molding machine, and added to the extruding in the molding machine. The length-to-diameter ratio of the screw is 32, the screw speed is 400-600r / min, and the hole die is 4-hole die. The temperature of the three sections in the screw is 155-165, 170-175, 155 respectively, and the temperature of th...

Embodiment 2

[0057] An asphalt temperature performance enhancer is composed of the following components according to the total weight percentage:

[0058] Ton bags with a PP content of not less than 80% account for 34%, 400-mesh montmorillonite PP-based masterbatch accounts for 17%, lake asphalt 22%, 80-mesh radial waste tire recycled rubber powder 18%, stabilizer Cadmium ricinoleate 2.2%, antioxidant tetrakis [methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 2.4%, low molecular weight polyethylene lubricant 2.0% , PP-based masterbatch 2.4%. A total of 8 kinds of ingredients are mixed in the pre-mixer at room temperature at a stirring speed of 2000r / min for about 5-15 minutes until they are evenly mixed, transported to the hopper of the extrusion molding machine, and added to the extruding in the molding machine. The length-to-diameter ratio of the screw is 32, the screw speed is 400-600r / min, and the hole die is 4-hole die. The temperature of the three sec...

Embodiment 3

[0062] An asphalt temperature performance enhancer is composed of the following components according to the total weight percentage:

[0063] Waste plastic bottles with a PET content of not less than 80% account for 36%, 200-mesh calcium oxide PE-based masterbatch accounts for 15%, semi-oxidized asphalt 24%, 60-mesh radial waste tire vulcanized rubber powder 18%, stabilizer Combination of calcium laurate and zinc palmitate at a ratio of 1:1 accounts for 2.0%, antioxidant β-(4-hydroxyphenyl-3,5-di-tert-butyl) n-octadecyl propionate 2.2%, PTFE wax lubricant 1.7%, PET-based black color masterbatch 1.9%. A total of 8 kinds of ingredients are mixed in the pre-mixer at room temperature at a stirring speed of 2000r / min for about 5-15 minutes until they are evenly mixed, transported to the hopper of the extrusion molding machine, and added to the extruding in the molding machine. The length-to-diameter ratio of the screw is 32, the screw speed is 400-600r / min, and the hole die is 4-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com