A kind of high thermal conductivity heat conduction glue and preparation method thereof

A technology of high thermal conductivity and thermally conductive adhesive, applied in the direction of non-polymer adhesive additives, adhesive additives, etc., can solve the problems of low thermal conductivity, high density, low stability, etc., to improve thermal conductivity and electrical conductivity performance, improve dispersion, and solve the effect of chip heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

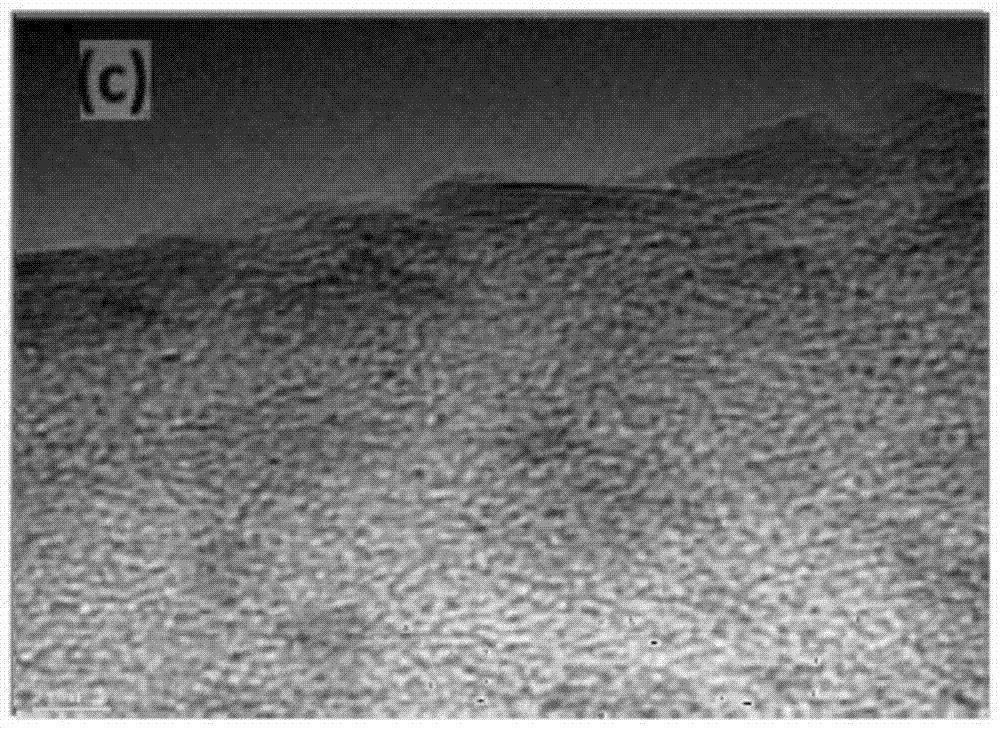

[0030] In order to further understand the technical means and characteristics of the present invention, I would like to give an example to further describe in detail in conjunction with the accompanying drawings:

[0031] The preparation method of thermally conductive adhesive of the present invention comprises the steps:

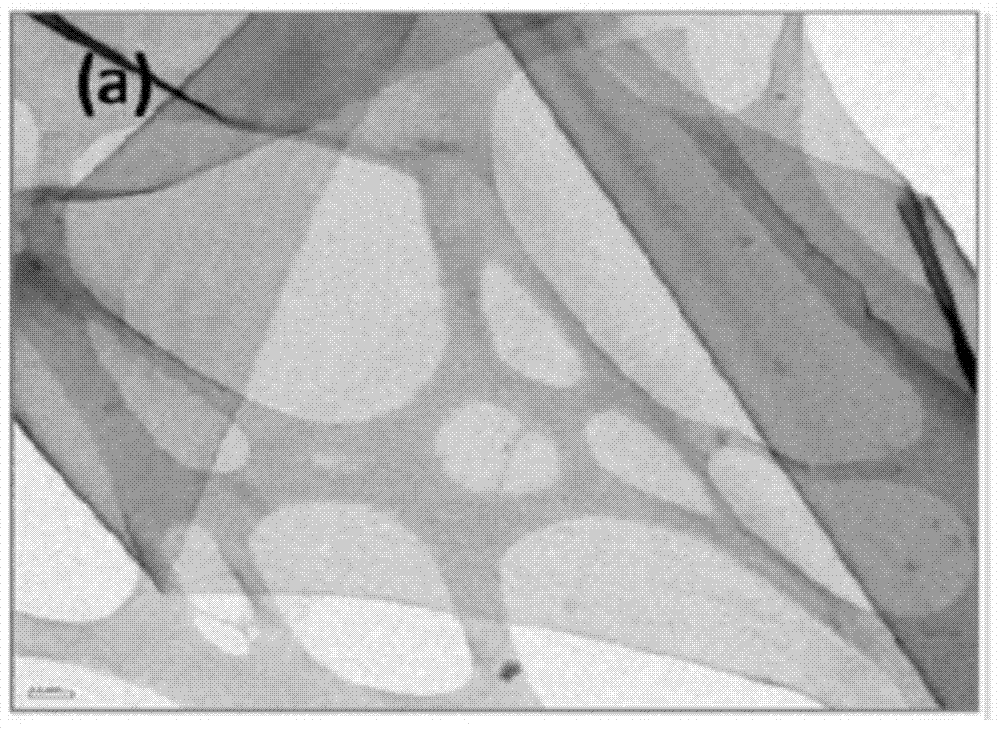

[0032] Step 1, prepare graphene oxide solution: first, oxidize and exfoliate natural scaly graphite powder in strong acid and strong oxidant to obtain graphene oxide; then put graphene oxide into deionized water, perform ultrasonic dispersion, and then centrifuge to remove untreated The exfoliated graphite particles are recovered to recover the supernatant, which is the graphene oxide solution.

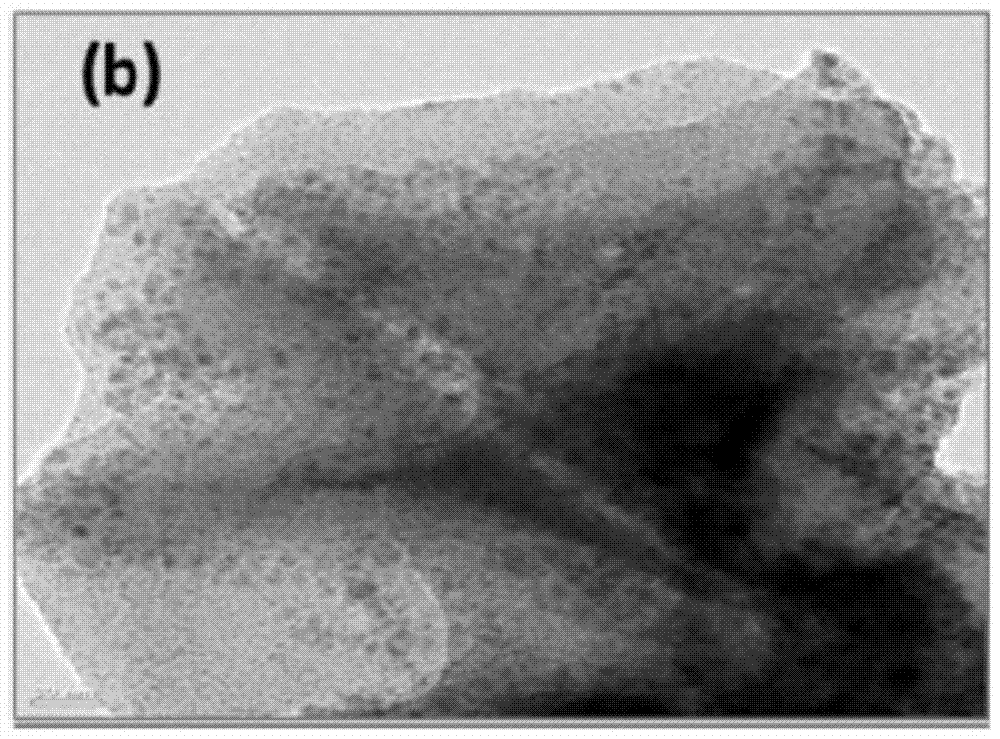

[0033] Step 2, graphene oxide reduction: add a first reducing agent to the graphene oxide solution, and perform a reduction reaction in an environment of 90-98° C. for 1 hour to reduce it into graphene particles.

[0034] In the third step, the reduced graphene pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com