Novel production method of sodium gluconate

A technology of sodium gluconate and a new method, applied in the field of sodium gluconate production, can solve the problems of high price and increased production cost, and achieve the effects of low cost, easy operation and short fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

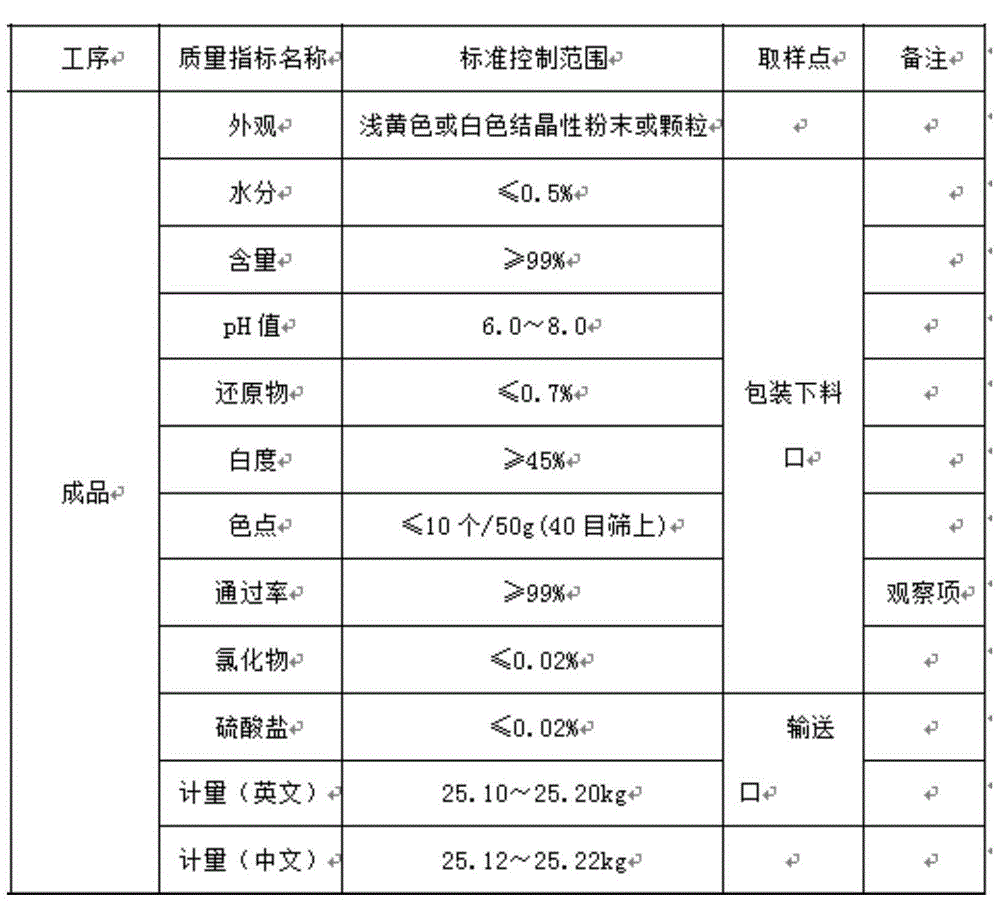

Image

Examples

Embodiment 1

[0040] Sodium gluconate production new method, concrete steps are as follows:

[0041] (1) Adjust the concentration and pH value of the qualified starch milk according to the process requirements, adjust the raw water to control the starch milk Baume degree 16-20, pH 5.3-5.8, add enzyme preparation in proportion, and the dosage of enzyme preparation is 0.5 Kg / T dry base starch, fully stir, and described enzyme preparation is aspergillus niger;

[0042] (2) Put the material obtained in step (1) into the injector, and the injection temperature is controlled at 105-115°C. The material is kept in the pipeline for 60-65 seconds, then enters the liquefaction tank, and keeps the temperature in the liquefaction tank at 80-85°C 30-35 minutes, the obtained material is liquefied liquid;

[0043] (3) Adjust the pH value of the liquefaction solution to 4.3-4.5; the temperature is 60-62°C, add glucoamylase according to the weight of dry starch, the dosage of glucoamylase is 0.45Kg / T dry st...

Embodiment 2

[0053] In step (1), the dosage of the enzyme preparation is 0.4Kg / T dry base starch, that is, 0.4kg enzyme preparation per ton of dry base starch.

[0054] In step (3), the amount of glucoamylase used is 0.55Kg / T dry base starch.

[0055] In step (7), the dosage of activated carbon is 2.0% of the weight of dry matter in the fermentation broth.

[0056] All the other technical features are the same as in Embodiment 1.

Embodiment 3

[0058] In step (1), the dosage of the enzyme preparation is 0.6Kg / T dry basis starch, that is, 0.6kg enzyme preparation per ton of dry basis starch.

[0059] In step (3), the amount of glucoamylase used is 0.38Kg / T dry base starch.

[0060] In step (7), the dosage of activated carbon is 4.0% of the weight of dry matter in the fermentation broth.

[0061] All the other technical features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com