Steel for marine hose armor layers in deep sea and preparation method thereof

An armoring layer and marine technology, which is applied in the field of steel for the armoring layer of deep-sea marine hoses and its preparation, can solve the problems of expensive nickel-based alloys, resistance to hydrogen sulfide stress corrosion, hydrogen-induced cracking corrosion, and hydrogen embrittlement corrosion. It is difficult to meet the requirements, limit the use and development, etc., to achieve the effect of excellent mechanical properties, high strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Smelt and cast according to the set composition to make continuous casting slab, its composition contains C 0.061%, Si 0.247%, Mn 1.48%, Cr 2.94%, Mo 0.31%, Al 0.02%, Ni 0.11%, S 0.003 by weight percentage %, P 0.015, the balance being Fe and unavoidable impurities;

[0033] Heat the continuous casting slab to 1220°C, control the heating rate at 6min / cm, and soak for 30min to make the austenite uniform, and control the temperature difference between the inside and outside of the continuous casting slab to be less than 30°C;

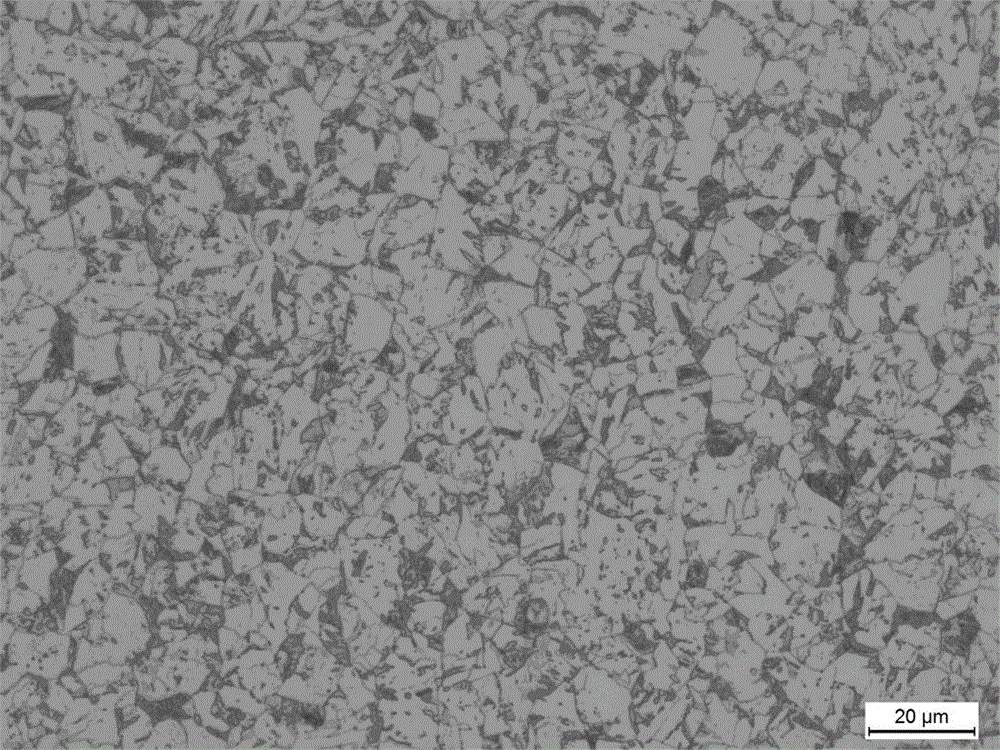

[0034] After the continuous casting slab is released from the furnace, hot rolling is completed on a high-speed wire rod rolling mill. The starting rolling temperature is 1150°C, the final rolling temperature is 920°C, and the compression ratio is 12; The spinning temperature is 810°C; the microstructure of the hot-rolled wire rod is as follows: figure 1 shown;

[0035] The hot-rolled wire rod after spinning is cooled on the Stelmo controlled coo...

Embodiment 2

[0040] It is smelted and cast according to the set composition to make continuous casting slab, and its composition contains C 0.12%, Si 0.35%, Mn 0.84%, Cr 2.16%, Mo 0.72%, Al 0.018%, Ni 0.23%, S 0.002% by weight %, P 0.013, the balance being Fe and unavoidable impurities;

[0041] Heat the continuous casting slab to 1160°C, control the heating rate at 8min / cm, and soak for 40min to make the austenite uniform, and control the temperature difference between the inside and outside of the continuous casting slab to be less than 30°C;

[0042] After the continuous casting slab is released from the furnace, it is hot-rolled on a high-speed wire rod mill. The starting temperature is 1120°C, the final rolling temperature is 930°C, and the compression ratio is 10; The spinning temperature is 830°C;

[0043] After spinning, the hot-rolled wire rod is cooled on the Stelmo controlled cooling line, and the delay type cooling is adopted with an insulating cover, the cooling rate is contr...

Embodiment 3

[0048] It is smelted and cast according to the set composition to make a continuous casting slab, and its composition contains C 0.16%, Si 0.49%, Mn 1.26%, Cr 1.11%, Mo 0.98%, Al 0.028%, Ni 0.28%, S 0.002% by weight %, P 0.012, the balance being Fe and unavoidable impurities;

[0049] Heat the continuous casting slab to 1150°C, control the heating rate at 10min / cm, and soak for 50min to make the austenite uniform, and control the temperature difference between the inside and outside of the continuous casting slab to be less than 30°C;

[0050] After the continuous casting slab is released from the furnace, it is hot-rolled on a high-speed wire rod rolling mill. The starting rolling temperature is 1100°C, the final rolling temperature is 950°C, and the compression ratio is 8; The spinning temperature is 850°C;

[0051] After spinning, the hot-rolled wire rod is cooled on the Stelmo controlled cooling line, and the delay type cooling is adopted with an insulating cover, the coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com