Preparation technology for high-temperature electrothermal film

A preparation process, electric heating film technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of low resistance, high hardness, high melting point, etc., and achieve high heat conversion rate, compact structure, and stable crystallization performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] S1. Take 100ml of alcohol and place it in a conical flask, heat it to 80°C, add 17.529g of tin tetrachloride and 0.57g of antimony trichloride to seal it, and stir at a constant temperature of 80°C for one hour;

[0014] S2. After the solution obtained in step S1 was left to stand for 2 hours, use a glue homogenizer to uniformly coat 15 layers of film on the quartz substrate at a speed of 5.0 kr / min. After the film coating is completed, cool down to room temperature naturally to deposit colloid;

[0015] S3. Place the quartz substrate obtained in step S2 in a high-temperature atmosphere furnace at 450° C. for sintering for 4 hours to obtain a finished product.

Embodiment 2

[0017] Take 100ml of alcohol and place it in a conical flask, heat it to 80°C, add 17.529g of tin tetrachloride and 0.57g of antimony trichloride to seal it, and stir at a constant temperature of 80°C for one hour;

[0018] S2. After the solution obtained in step S1 was left to stand for 2 hours, use a glue homogenizer to uniformly coat 20 layers of film on the quartz substrate at a speed of 5.0 kr / min. After the film coating is completed, naturally cool down to room temperature and deposit the colloid;

[0019] S3. Place the quartz substrate obtained in step S2 in a high-temperature atmosphere furnace at 450° C. for sintering for 4 hours to obtain a finished product.

Embodiment 3

[0021] Take 100ml of alcohol and place it in a conical flask, heat it to 80°C, add 17.529g of tin tetrachloride and 0.57g of antimony trichloride to seal it, and stir at a constant temperature of 80°C for one hour;

[0022] S2. After the solution obtained in step S1 was left to stand for 2 hours, use a glue homogenizer to uniformly coat 18 layers of film on the quartz substrate at a speed of 5.0 kr / min. After the film coating is completed, cool down to room temperature naturally to deposit the colloid;

[0023] S3. Place the quartz substrate obtained in step S2 in a high-temperature atmosphere furnace at 450° C. for sintering for 4 hours to obtain a finished product.

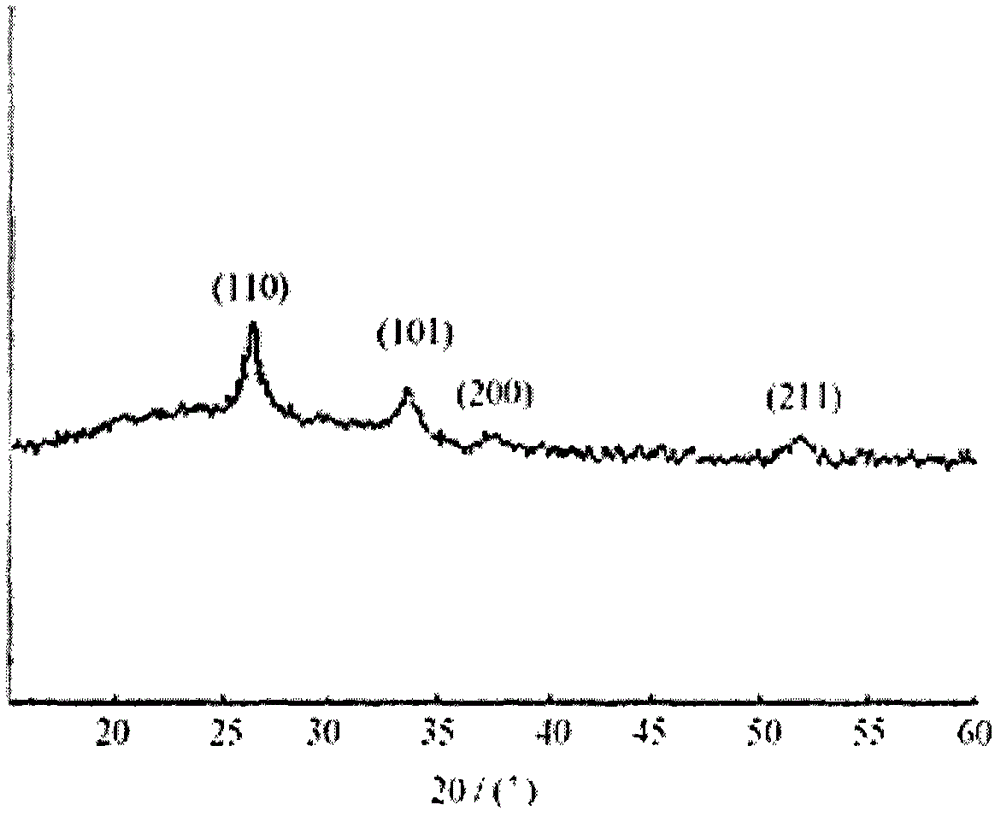

[0024] After testing, the XRD spectrum of the film structure obtained in Examples 1-3 at a temperature of 450°C is as follows: figure 1 shown.

[0025] The present invention can prepare thin films under lower temperature conditions, can accurately control the amount of dopant, and can prepare larger area SnO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com