Manufacturing method for traceable high-corrosion-resistance three-piece aerosol can

A manufacturing method and technology of aerosol cans, applied in the direction of manufacturing tools, devices for coating liquid on the surface, resistance welding equipment, etc., can solve the problem of finding the cause of untraceable production information, pitting corrosion in the weld repair area, and no products Retrace solutions and other issues to achieve the effect of broadening product usage, protection without corrosion, and constant and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

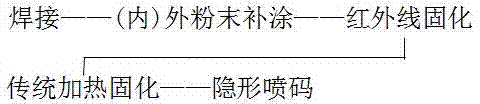

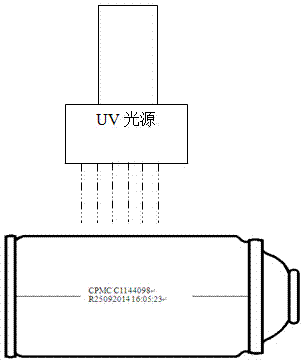

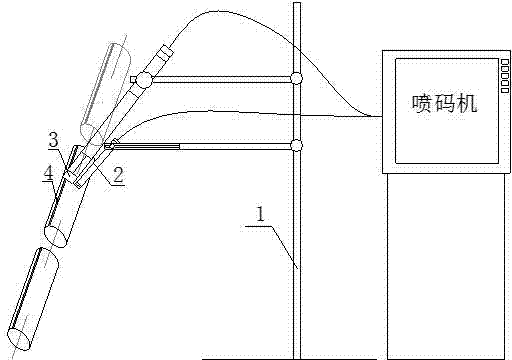

[0018] see Figure 1-Figure 3 , the process steps of the present invention are described in detail.

[0019] 1. Welding.

[0020] Three flat pieces of aerosol cans are combined by resistance welding, and the size of the unilateral gap of the weld is controlled at 2.5-3.25mm. Unspecified parts are the same as the prior art.

[0021] 2. Powder coating inside and outside.

[0022] The same thermoplastic polyester resin powder coating is sprayed on the inner and outer edge areas of the weld, and after being solidified by electrostatic adsorption, the inner weld repair tape and the outer weld repair tape are formed. The main composition of thermoplastic polyester powder coating (m / m): polyester resin 90-95%, leveling agent 2 , the powder and the welding seam are left blank and the internal paint overlap size is recommended to be 1 2mm.

[0023] Taking COFCO Packaging's high corrosion resistance aerosol cans as an example, the formula of thermoplastic polyester powder coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com