Device and method for recycling and extracting high-purity SF6 gas by employing membrane separation method

A membrane separation method and recovery device technology, which is applied in the direction of sulfur and halogen compounds, can solve the problems of complex devices and methods, and achieve the effects of simple operation, strong controllability, and reduced irreversible impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

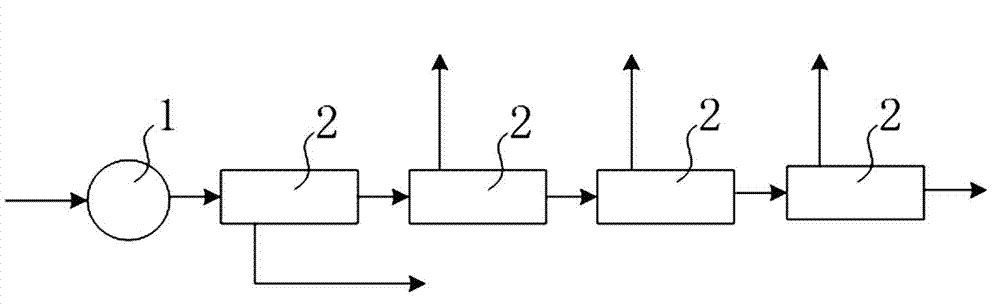

[0041] A method of recovering and extracting high-purity SF by membrane separation method 6 The gas device includes a compressor 1 and a membrane separation and recovery device connected behind the compressor 1; the membrane separation and recovery device is composed of N hollow fiber membranes 2 connected in sequence, where N≥4.

[0042] In this embodiment, the number N of the hollow fiber membranes 2 is preferably set to four stages, which are sequentially named as the first-stage hollow fiber membrane, the second-stage hollow fiber membrane, the third-stage hollow fiber membrane and the fourth-stage hollow fiber membrane along the gas flow direction. ,Such as figure 1 shown. At the same time, the first-stage hollow fiber membranes, the second-stage hollow fiber membranes, the third-stage hollow fiber membranes and the fourth-stage hollow fiber membranes in the present invention can be selected in different sizes according to the amount of recycled gas.

[0043] Utilize ab...

Embodiment 2

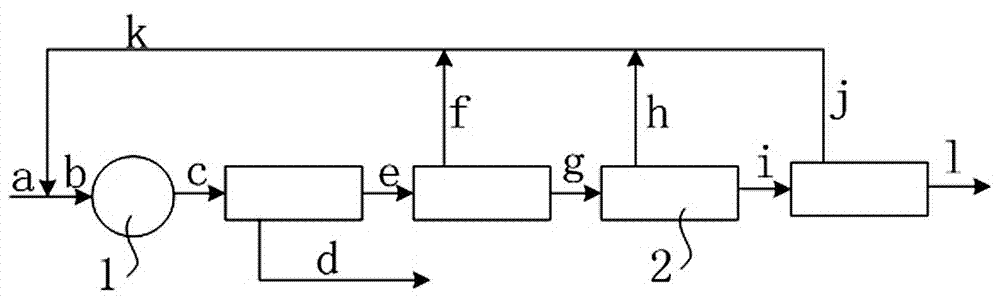

[0049] The difference between this embodiment and Embodiment 1 is that: in the device of the present invention, each hollow fiber membrane 2 has a permeate side exhaust port; The exhaust port on the permeate side of the membrane 2 communicates with the atmosphere, and the exhaust port on the permeate side of the remaining hollow fiber membranes 2 communicates with the air inlet of the compressor 1, as figure 2 shown.

[0050] In this embodiment, the device of this embodiment is used to SF 6 Gas purification methods are as follows:

[0051] (1) will SF 6 After the recovered gas with a content of 2.2% is pressurized by the compressor, a mixed gas with a pressure of 0.7MPaG is obtained, and the mixed gas is passed into the first-stage hollow fiber membrane; SF in a part of the gas separated by the first-stage hollow fiber membrane 6 The content is less than 0.1%, so it meets the gas emission standard and can be discharged directly;

[0052] (2) The recovered gas obtained aft...

Embodiment 3

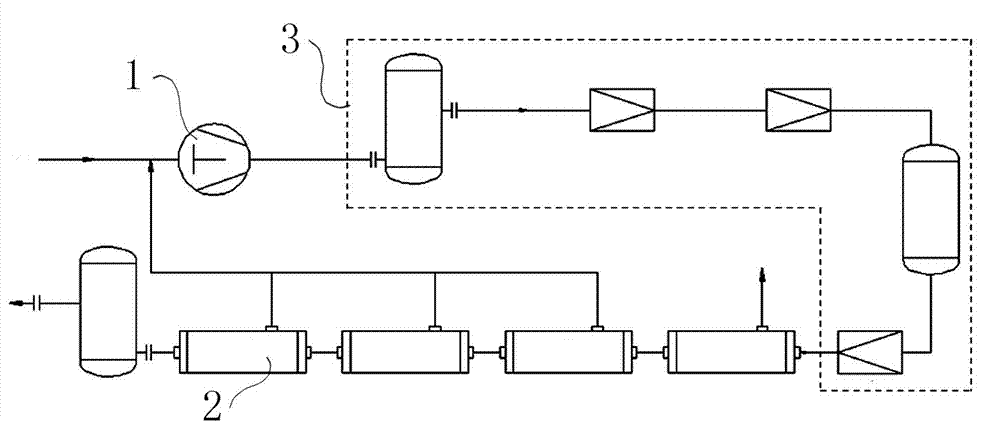

[0060] The difference between this embodiment and Embodiment 2 is that a gas pretreatment purification system is added in this embodiment, and the specific setting method is as follows:

[0061] A gas pretreatment and purification system 3 is also provided between the compressor 1 and the membrane separation and recovery device. The gas pretreatment and purification system 3 includes a compressed gas buffer tank, a precision filter, an ultrafine filter, an active carbon filter and a dust filter connected in sequence along the gas flow direction, such as image 3 shown.

[0062] Further, for the convenience of control, the rear end of the membrane separation and recovery device is also connected with SF 6 The product gas buffer tank, the rear end of the membrane separation and recovery device is also provided with a flow meter and a valve for adjusting the gas flow.

[0063] In this embodiment, the device of this embodiment is used to SF 6 Gas purification methods are as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com