Treatment method of fosfomycin calcium salt-containing high-concentration organic process wastewater

A technology of fosfomycin calcium and its treatment method, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, organic chemistry, etc., and can solve the problems of difficult safety guarantee, high temperature and pressure, equipment investment and operation cost High cost and other problems, to achieve the effect of small investment, lower pollution load, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

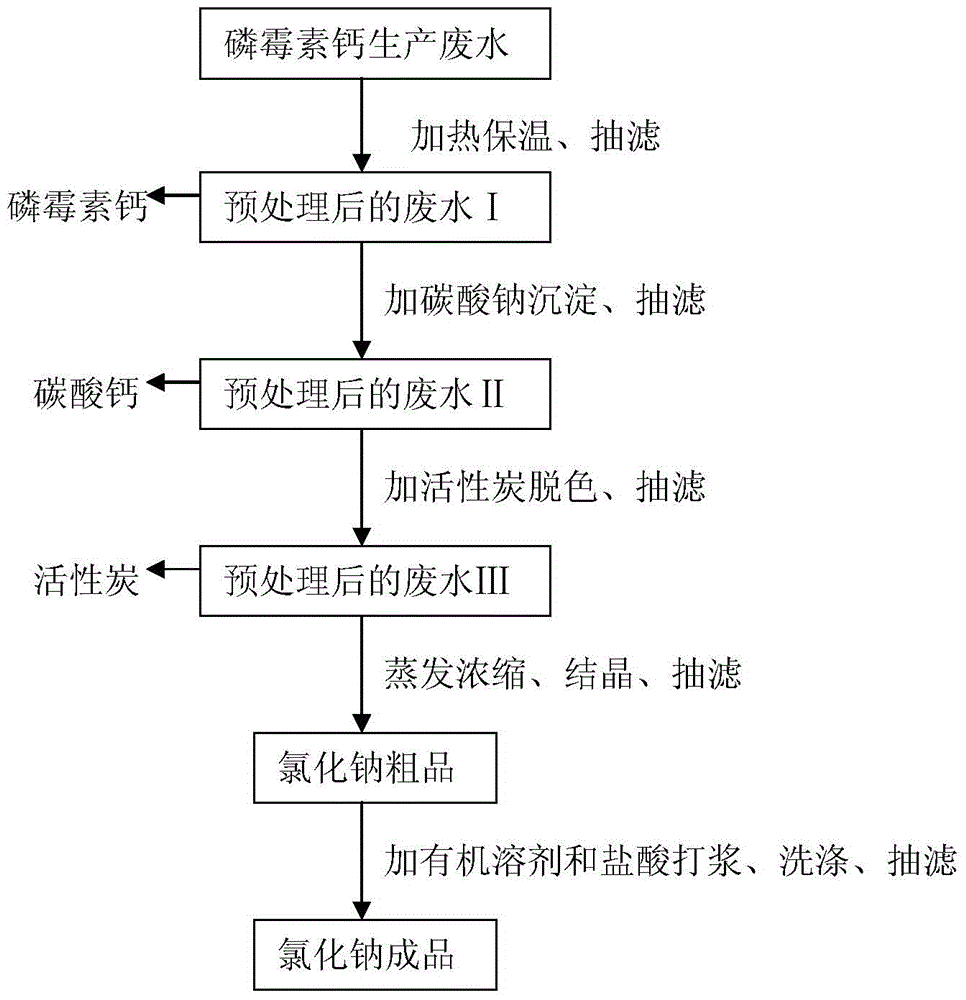

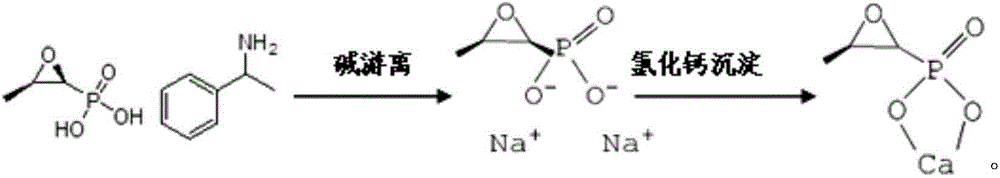

[0081] Embodiment 1, the comprehensive treatment and resource utilization method of the saline high-concentration organic process wastewater produced in the production process of fosfomycin calcium, the saline high-concentration organic process wastewater is produced in the production process of fosfomycin calcium; Follow the steps in order:

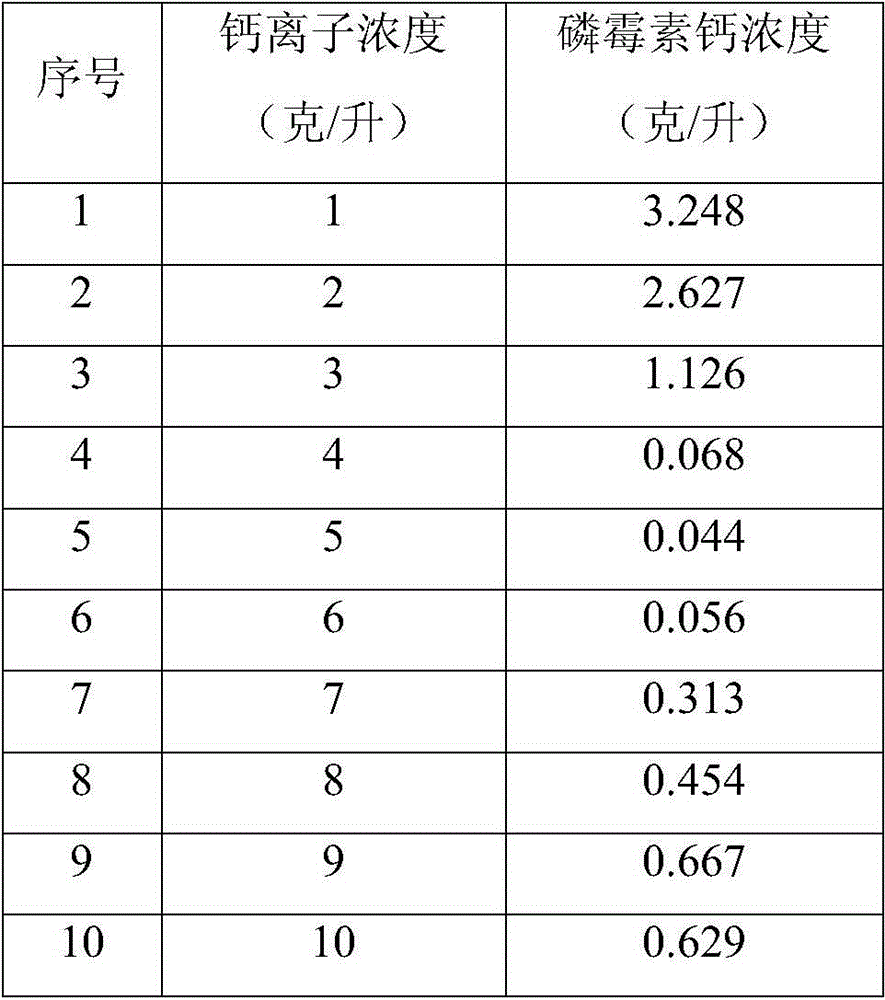

[0082] 1), take 50 liters of salt-containing high-concentration organic process wastewater (collected from the wastewater storage tank of the company's fosfomycin calcium production workshop) produced in the production process of fosfomycin calcium, and the concentration of calcium ions is 1.2 grams per liter. Add about 537 grams of anhydrous calcium chloride to the water, adjust the calcium ion concentration in the waste water to 5 grams per liter, heat it to 70°C, keep it warm for 30 minutes, and suction filter while it is hot to get 180 grams of fosfomycin calcium crude product and about 50 liters of pre- Treated waste water I, fosfom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com