Road design method and mixing method

A technology for road design and mix ratio design, which is applied in the field of mixing process and mix ratio design of semi-flexible asphalt mixture, can solve the problems of difficult to grasp the effect of slurry injection, difficult to control quality, and many construction procedures, and to overcome the high temperature stability. The effect of reducing energy consumption and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

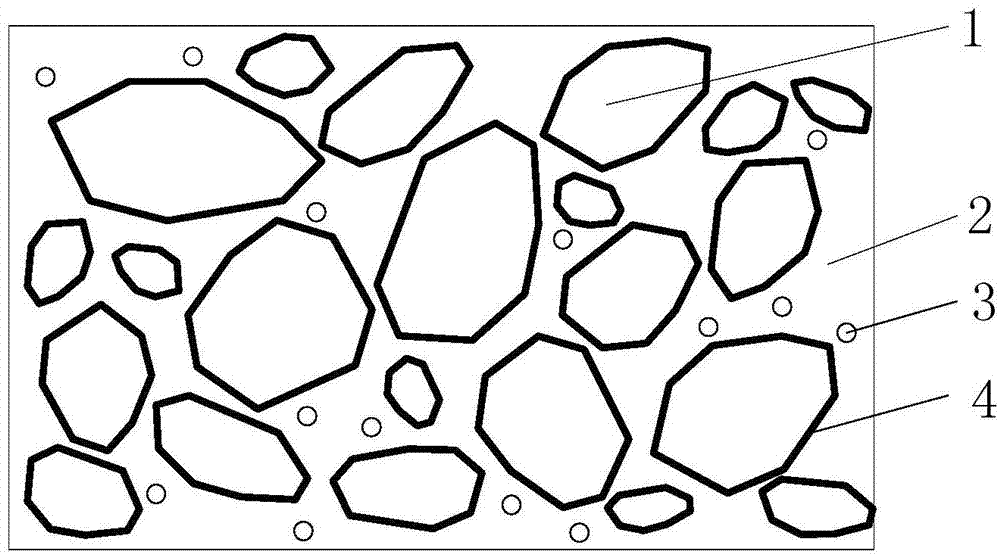

[0064] Embodiment: The mixing ratio design and mixing process of direct-mix semi-flexible normal temperature asphalt mixture SFAC-10 with a final porosity of 4% includes the following steps:

[0065] (1) Basic data of raw materials

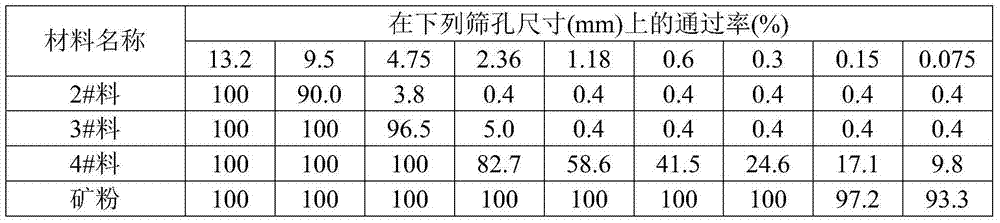

[0066] The mineral materials used in the mix ratio design are 3 kinds of aggregates and 1 kind of mineral powder with different specifications. The screening results of various mineral materials are shown in Table 1.

[0067] Table 1 Mineral screening results

[0068]

[0069] The bitumen used in the mix ratio design is cationic modified emulsified bitumen, the demulsification time is 2min, and the solid content is 61% obtained by the evaporation residue test.

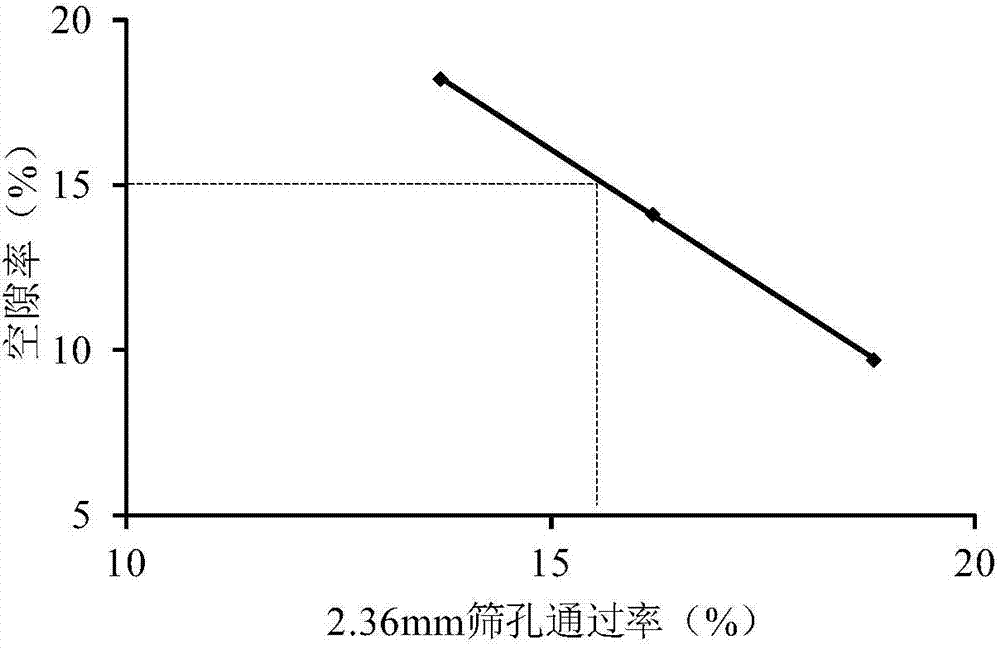

[0070] (2) Mineral material gradation design of the mixture matrix

[0071] Since the nominal maximum particle size of the semi-flexible asphalt mixture SFAC-10 is 9.5 mm, the gradation range of OGFC-10 with a nominal maximum particle size of 9.5 mm was selected in the "Technical Spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com