A kind of electric porcelain added with cab2o4 seed crystal and cab2o4 seed amorphous and its preparation method

A technology of seed amorphous and seed crystal, which is applied in the field of electric porcelain with CaB2O4 seed crystal and CaB2O4 seed amorphous and its preparation, can solve the problems of uneven product quality, insufficient strength of electric porcelain, poor process level, etc., and achieve improved flow high performance, stable and mature process, and the effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method comprises the following steps:

[0025] (1) Batching; raw materials are baked at 90~100°C for 12 hours, weighed according to the formula, and compounded;

[0026] (2) Ball milling: zirconium balls are used, the volume ratio of balls to materials is 2:1, and they are passed through a 270-mesh sieve;

[0027] (3) Iron removal, mud squeezing, staleness, and mud refining: Use electromagnetic coils and permanent magnet iron removal equipment to sieve and remove iron. After adding water to squeeze the mud, the moisture content is 22%, the aging time is 72h, and the vacuum degree is 0.05~0.09 Practicing mud under MPa;

[0028] (4) Molding: Extrusion molding is carried out under a vacuum degree of 0.01MPa, and the molded sample is a columnar shape with a diameter of 2.3cm and a length of 13.6cm;

[0029] (5) Drying; first dry in the shade for 12 hours, then bake at 90~100°C for 48 hours;

[0030] (6) Kiln sintering; the heating rate is 5°C / min, the sin...

Embodiment 1

[0033] Embodiment 1: Preparation and sintering of electric porcelain

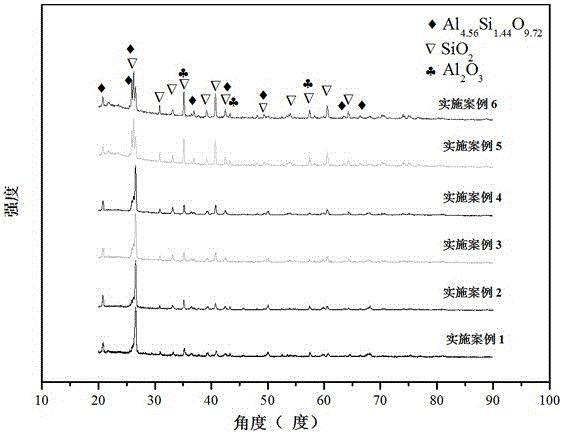

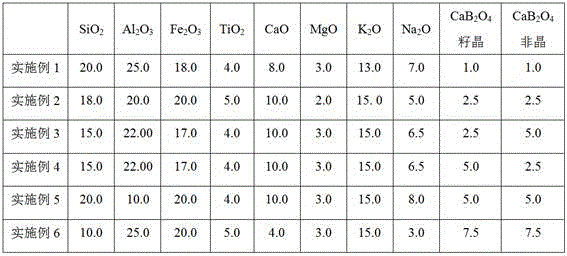

[0034] According to the ratio of each component in Table 1, weigh a certain amount of raw materials (Puxian soil, Xiaxi soil, panning soil, lithium feldspar, Zhangzhou soil, coke gem, feldspar powder, bauxite, composite seed crystal ), and then perform ball milling, iron removal, mud pressing, aging, mud refining, molding and drying in sequence according to the aforementioned ceramic preparation steps. The dried samples were placed in a programmable furnace for sintering. Add 2% composite seed (CaB 2 o 4 Seed and CaB 2 o 4 The phase composition of the sample after sintering at 1230℃ is as follows: figure 1shown. According to quantitative analysis, the mass percentage of mullite phase (ICCD79-1458) contained in this sample is 15.2%. The fracture strength of the sample is low, only 1366±10MPa.

Embodiment 2

[0035] Embodiment 2: Preparation and sintering of electric porcelain

[0036] According to the ratio of each component in Table 1, weigh a certain amount of raw materials (Puxian soil, Xiaxi soil, panning soil, lithium feldspar, Zhangzhou soil, coke gem, feldspar powder, bauxite, composite seed crystal ), and then prepare electric porcelain according to the process of Example 1. Such as figure 1 As shown, adding 5% composite seed (CaB 2 o 4 Seed and CaB 2 o 4 The content of mullite phase can be further increased after sintering at 1230 °C for samples with 2.5% seed amorphous. Among them, the mass percentage of mullite phase is 17.6%. At this time, the fracture strength of the sample is 1421±10MPa, which is improved compared with the original formula.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com