Benzoic acid based anhydrous and solvent-free method for preparing heptanaphthenic acid

A technology for cyclohexanecarboxylic acid and benzoic acid, which is applied in the preparation of carboxylic acids by ozone oxidation, organic chemistry, etc., can solve the problems of difficult solvent separation, harsh reaction conditions, and low product yields, and achieves advanced technical routes, high selectivity, and The effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

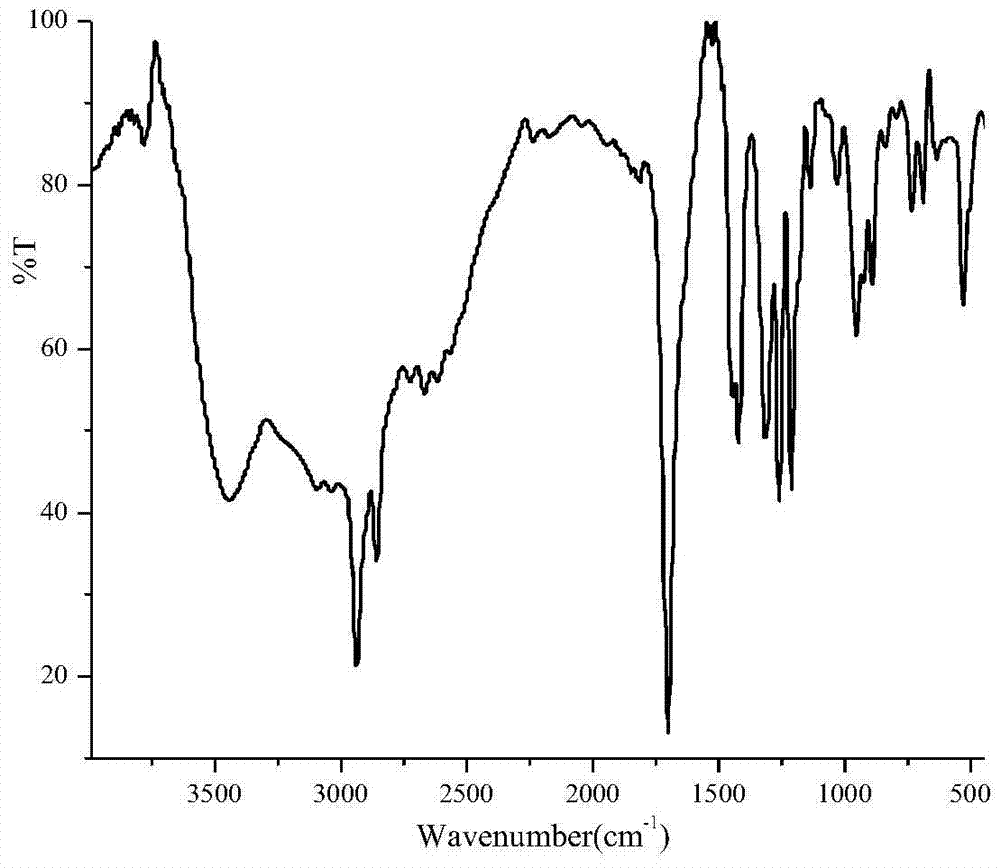

Image

Examples

Embodiment 1

[0059] Weigh benzoic acid and catalyst respectively according to the mass ratio of 7:1;

[0060] The weighed benzoic acid is placed in a heating container for heating and dissolving, and the heating temperature is controlled at 100° C. to obtain the benzoic acid after heating;

[0061] Take the hydrogenation reactor, add the hot-dissolved benzoic acid together with the weighed catalyst into the hydrogenation reactor; heat the hydrogenation reactor, and feed nitrogen into the hydrogenation reactor after heating to room temperature; Heating, when the temperature in the hydrogenation reactor reaches 150°C and the pressure is 1MPa, and the pressure in the hydrogenation reactor is stable at 1MPa and does not absorb hydrogen, the hydrogenation reactor is cooled to At 70°C, open the hydrogenation reactor to obtain reactants; filter the obtained reactants to obtain crude cyclohexanecarboxylic acid;

[0062] Put the crude cyclohexanecarboxylic acid into the rectification tower, after ...

Embodiment 2

[0064] Take respectively benzoic acid and catalyst according to the mass ratio of 8:1;

[0065] The weighed benzoic acid is placed in a heating container for heating and dissolving, and the heating temperature is controlled at 120° C. to obtain hot-dissolved benzoic acid;

[0066] Take the hydrogenation reactor, add the hot-dissolved benzoic acid together with the weighed catalyst into the hydrogenation reactor; heat the hydrogenation reactor, and feed nitrogen into the hydrogenation reactor after heating to room temperature; Heating, when the temperature in the hydrogenation reactor reaches 160°C, the pressure is 1.2MPa, and the pressure in the hydrogenation reactor is stable at 1.2MPa, and no hydrogen is absorbed, the hydrogenation reactor is cooled, and the hydrogenation reactor Lower the temperature to 75°C, open the hydrogenation reactor to obtain reactants; filter the obtained reactants to obtain crude cyclohexanecarboxylic acid;

[0067] Put the crude cyclohexanecarbox...

Embodiment 3

[0069] Take respectively benzoic acid and catalyst according to the mass ratio of 9:1;

[0070] The weighed benzoic acid is placed in a heating container for heating and dissolving, and the heating temperature is controlled at 140° C. to obtain hot-dissolved benzoic acid;

[0071] Take the hydrogenation reactor, add the hot-dissolved benzoic acid together with the weighed catalyst into the hydrogenation reactor; heat the hydrogenation reactor, and feed nitrogen into the hydrogenation reactor after heating to room temperature; Heating, when the temperature in the hydrogenation reactor reaches 170°C, the pressure is 1.5MPa, and the pressure in the hydrogenation reactor is stable at 1.5MPa, and no hydrogen is absorbed, the hydrogenation reactor is cooled, and the hydrogenation reactor Cooling down to 80°C, opening the hydrogenation reactor to obtain reactants; filtering the obtained reactants to obtain crude cyclohexanecarboxylic acid;

[0072] Put the crude cyclohexanecarboxyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com