Three-layer concentric high-performance fiber composite material cable core rod and manufacturing method thereof

A composite core, high-performance fiber technology, used in cable/conductor manufacturing, power cables, insulated cables, etc., can solve the problems of high glass fiber density, complex process, and increased weight of composite core rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

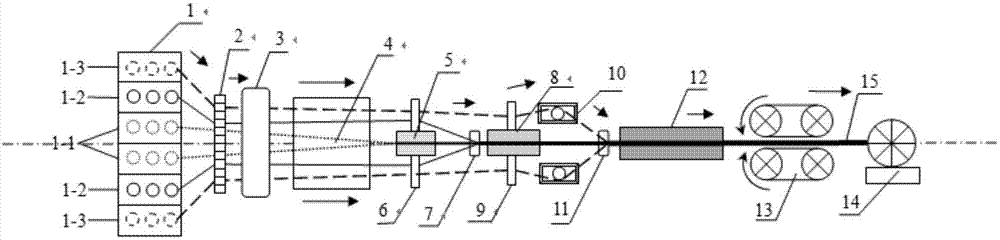

[0035] 1), fix the carbon fiber yarn 1-1, glass fiber yarn 1-2, and aramid fiber yarn 1-3 on the creel 1, and make the yarn bundle pass through the yarn guide plate 2, keep the carbon fiber in the center, and the glass fiber and aramid fiber The fibers are left and right symmetrical, and are distributed on both sides of the carbon fiber from the inside to the outside in order to adjust the tension and prevent the fibers from sagging and winding.

[0036] 2) The above three kinds of fibers are dehumidified through the drying equipment 3, and then enter the glue tank 4 to soak the liquid resin.

[0037] 3) The carbon fiber impregnated with the resin first passes through the first pre-curing mold 5 to form a preformed mandrel of carbon fiber composite material, and the glass fiber and aramid fiber pass through the first dividing plate 6 outside the pre-curing mold 5 .

[0038] 4), passing through the first yarn dividing plate 6 and the first circular yarn collecting plate 7 throu...

Embodiment 2

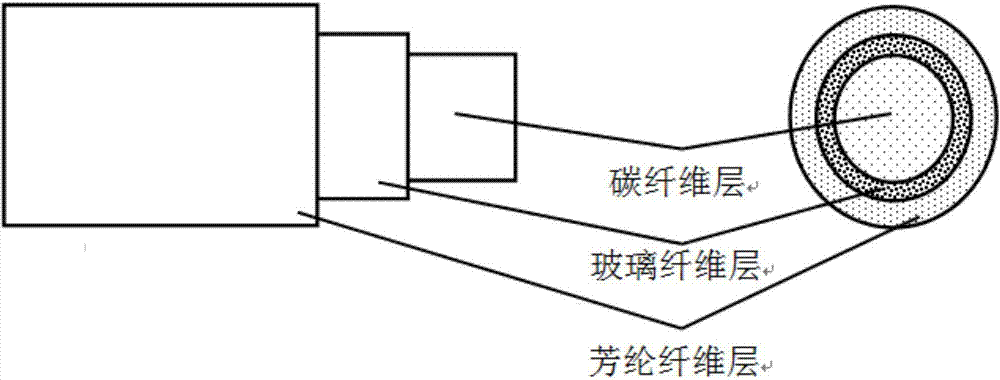

[0059] A three-layer concentric high-performance fiber composite cable mandrel, the mandrel is an epoxy resin-based composite mandrel containing carbon fiber, glass fiber, and aramid fiber, composed of a carbon fiber inner layer at the inner core position, A glass fiber middle layer coated on the outside of the carbon fiber inner layer, and an aramid fiber outer layer wrapped on the outside of the glass fiber middle layer. In the cross section of the mandrel, the carbon fiber inner layer, the glass fiber middle layer and the The outer circumference of the aramid fiber outer layer is concentric circles. The mandrel includes the following components: 35 parts of carbon fiber, 10 parts of glass fiber, 15 parts of aramid fiber, and 20 parts of resin, in parts by volume. Manufactured by the method described in Example 1.

Embodiment 3

[0061] A three-layer concentric high-performance fiber composite cable mandrel, the mandrel is an epoxy resin-based composite mandrel containing carbon fiber, glass fiber, and aramid fiber, composed of a carbon fiber inner layer at the inner core position, A glass fiber middle layer coated on the outside of the carbon fiber inner layer, and an aramid fiber outer layer wrapped on the outside of the glass fiber middle layer. In the cross section of the mandrel, the carbon fiber inner layer, the glass fiber middle layer and the The outer circumference of the aramid fiber outer layer is concentric circles. The mandrel includes the following components: 45 parts of carbon fiber, 15 parts of glass fiber, 25 parts of aramid fiber, and 45 parts of resin, in parts by volume. Manufactured by the method described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com