Good-effect antibiotic mosquito-repellent fabric and making method thereof

A technology for repelling mosquitoes and fabrics, applied in the field of fabrics, can solve the problems of antibacterial and antiviral treatment in the budding state, and achieve the effect of raw material source method, low cost, and excellent antibacterial and mosquito repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

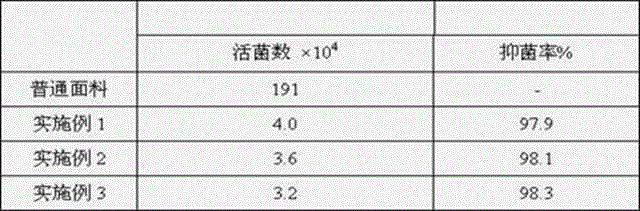

Examples

Embodiment 1

[0019] The antibacterial mosquito repellent fabric with good effect comprises a base fabric layer, a fabric layer and an antibacterial mosquito repellent layer arranged between the base fabric layer and the fabric layer; the antibacterial mosquito repellent layer is woven from warp and weft; the The warp is an antibacterial fiber treated with an antibacterial finishing solution; the weft is an antibacterial fiber treated with a mosquito repellent finishing solution.

[0020] The base cloth layer is milk protein fiber, the fabric layer is polyacrylonitrile fiber, and the antibacterial fiber is soybean protein fiber, cotton fiber, bamboo charcoal fiber, viscose fiber, spandex or acrylic fiber; the base cloth layer and The thickness of the fabric layer is 0.6 μm.

[0021] The preparation of antibacterial fiber comprises the following steps:

[0022] Preparation of antibacterial finishing solution: decoct Radix Isatidis, Coptis Rhizoma, Houttuynia cordata, Folium Isatidis, Be...

Embodiment 2

[0029] The antibacterial mosquito repellent fabric with good effect comprises a base fabric layer, a fabric layer and an antibacterial mosquito repellent layer arranged between the base fabric layer and the fabric layer; the antibacterial mosquito repellent layer is woven from warp and weft; the The warp is an antibacterial fiber treated with an antibacterial finishing solution; the weft is an antibacterial fiber treated with a mosquito repellent finishing solution.

[0030] The base cloth layer is milk protein fiber, the fabric layer is polyacrylonitrile fiber, and the antibacterial fiber is soybean protein fiber, cotton fiber, bamboo charcoal fiber, viscose fiber, spandex or acrylic fiber; the base cloth layer and The thickness of the fabric layer is 0.4 μm.

[0031] The preparation of antibacterial fiber comprises the following steps:

[0032] Preparation of mosquito repellent finishing solution: decoct mugwort leaves, perilla, vanilla, clove, mint, eucalyptus leaves, ...

Embodiment 3

[0039] The antibacterial mosquito repellent fabric with good effect includes a base fabric layer, a fabric layer and an antibacterial mosquito repellent layer arranged between the base fabric layer and the fabric layer; the antibacterial mosquito repellent layer is woven from warp and weft; the The warp is an antibacterial fiber treated with an antibacterial finishing solution; the weft is an antibacterial fiber treated with a mosquito repellent finishing solution.

[0040] The base cloth layer is milk protein fiber, the fabric layer is polyacrylonitrile fiber, and the antibacterial fiber is soybean protein fiber, cotton fiber, bamboo charcoal fiber, viscose fiber, spandex or acrylic fiber; the base cloth layer and The thickness of the fabric layer is 0.8 μm.

[0041] The preparation of antibacterial fiber comprises the following steps:

[0042] Preparation of mosquito repellent finishing solution: decoct mugwort leaves, perilla, vanilla, clove, mint, eucalyptus leaves, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com