Method for preparation of polyvinyl alcohol embolism microball by synchronous solidification

A technology for embolizing microspheres and polyvinyl alcohol with polyvinyl alcohol, which is used in medical science, surgery, etc., can solve the problems of poor control of product sphericity, difficulty in particle size uniformity of microspheres, etc., and achieve controllable particle size. Preparation, avoid microsphere morphology deformation, avoid cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, the preparation of polyvinyl alcohol aqueous solution

[0047] Weigh 10 grams of polyvinyl alcohol particles (average molecular weight 22,000, hydrolysis 99.2%), add 90 grams of distilled water, stir at 75-80°C for 4 hours, and then dissolve into a transparent liquid to obtain a 10% by weight aqueous solution of polyvinyl alcohol .

[0048] As mentioned above, in the same operation, weigh 5 grams of polyvinyl alcohol particles and add 95 grams of distilled water, stir at 75-80° C. for 3.5 hours, and then uniformly dissolve into a transparent liquid to obtain a 5% by weight aqueous solution of polyvinyl alcohol.

Embodiment 2

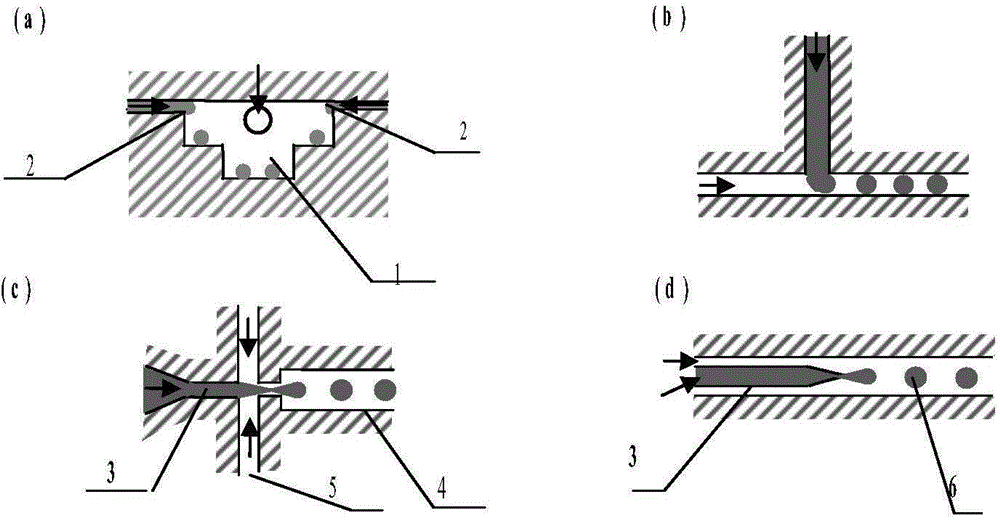

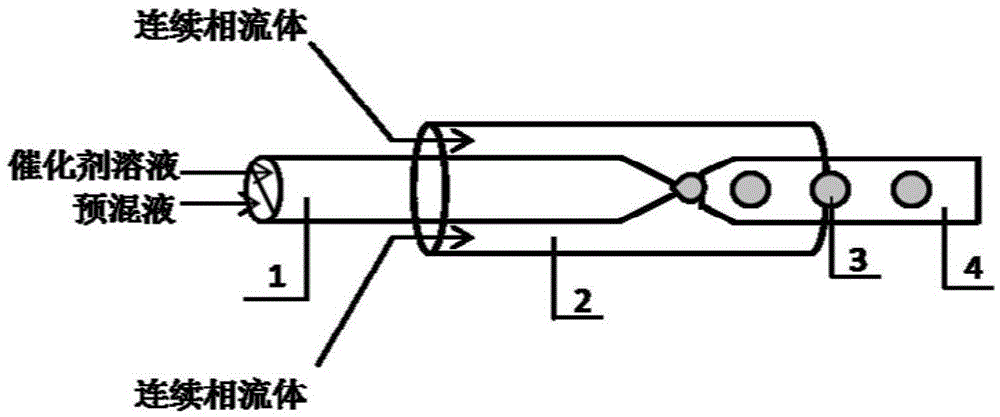

[0049] Embodiment 2, co-flow micro-scale channel, such as figure 2 As shown, the emission microchannel 3 and the continuous phase fluid microchannel 5 are coaxially connected. The discrete phase fluid flows out through the emission microchannel and is in the same flow direction as the continuous phase fluid. Channel junctions are formed near and collected by droplet collection microchannels 4 .

Embodiment 3

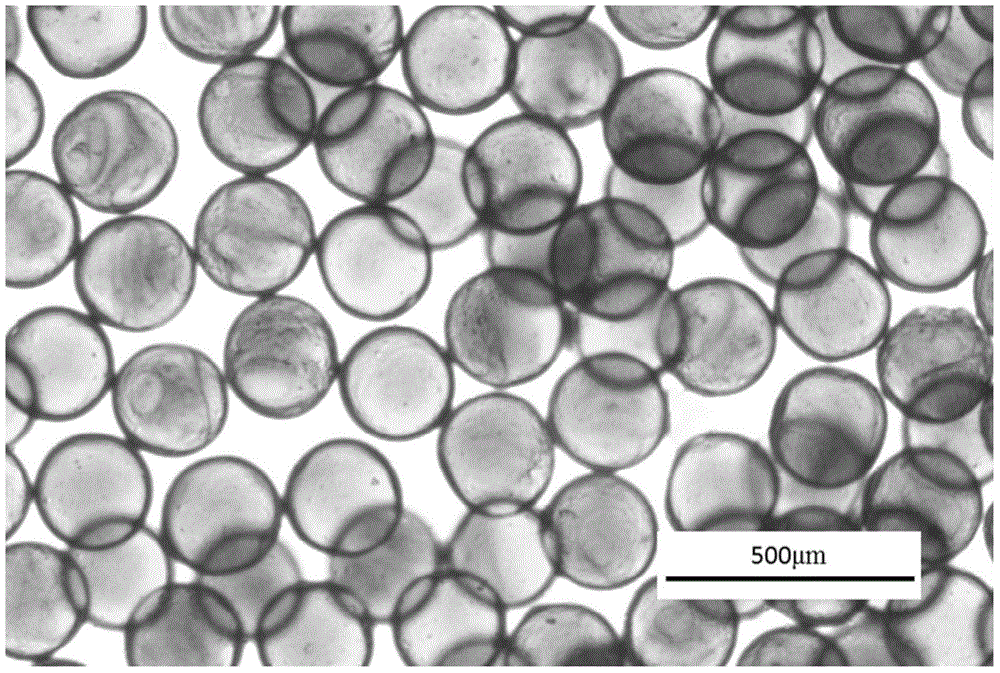

[0050] Embodiment 3, preparation of polyvinyl alcohol microspheres:

[0051] Choose (d) the micro-scale channel of the co-flow channel structure, such as figure 2 As shown, the outlet diameter of the discrete phase fluid channel in the microscale channel is 50 microns, and the diameter of the continuous phase fluid channel is 1000 microns.

[0052] The concentration of the polyvinyl alcohol aqueous solution is 5% by weight, and the aqueous solution of the crosslinking agent is a glutaraldehyde aqueous solution of 50% by weight. The polyvinyl alcohol aqueous solution and the glutaraldehyde The aqueous solution is premixed, and the catalyst aqueous solution is 1 mol / L hydrochloric acid aqueous solution. The premixed solution of polyvinyl alcohol and crosslinking agent and the aqueous catalyst solution were pumped into the discrete phase fluid channel at a constant flow rate of 2mL / h and 0.2mL / h, while liquid paraffin was pumped into the continuous phase at a constant flow rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com