New method for quick preparation of high-purity cadmium telluride powder

A technology of cadmium telluride and a new method, which is applied in the field of new energy photoelectric material preparation, can solve the problems that restrict the batch preparation and commercial application of cadmium telluride, high equipment dependence, long synthesis cycle, etc., and achieve high efficiency, energy saving and temperature rise The effect of speed, avoidance of process flow, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A new method for rapidly preparing high-purity cadmium telluride powder, comprising the following steps:

[0026] 1) Mix 4N cadmium powder and 4N tellurium powder at a molar ratio of 1:1, the total mass of the raw materials is 5g, and then grind and mix the raw material powders evenly to obtain the mixed raw materials;

[0027] 2) cold pressing the mixed raw material obtained in step 1) into a cylindrical block body with a diameter of 10mm, wherein the pressing process is to hold the pressure at 3MPa for 5min;

[0028] 3) The bulk green body obtained in step 2) is ignited at one end to initiate a high-temperature self-propagating synthesis reaction. After the reaction is completed, it is naturally cooled and ground to obtain high-purity cadmium telluride powder.

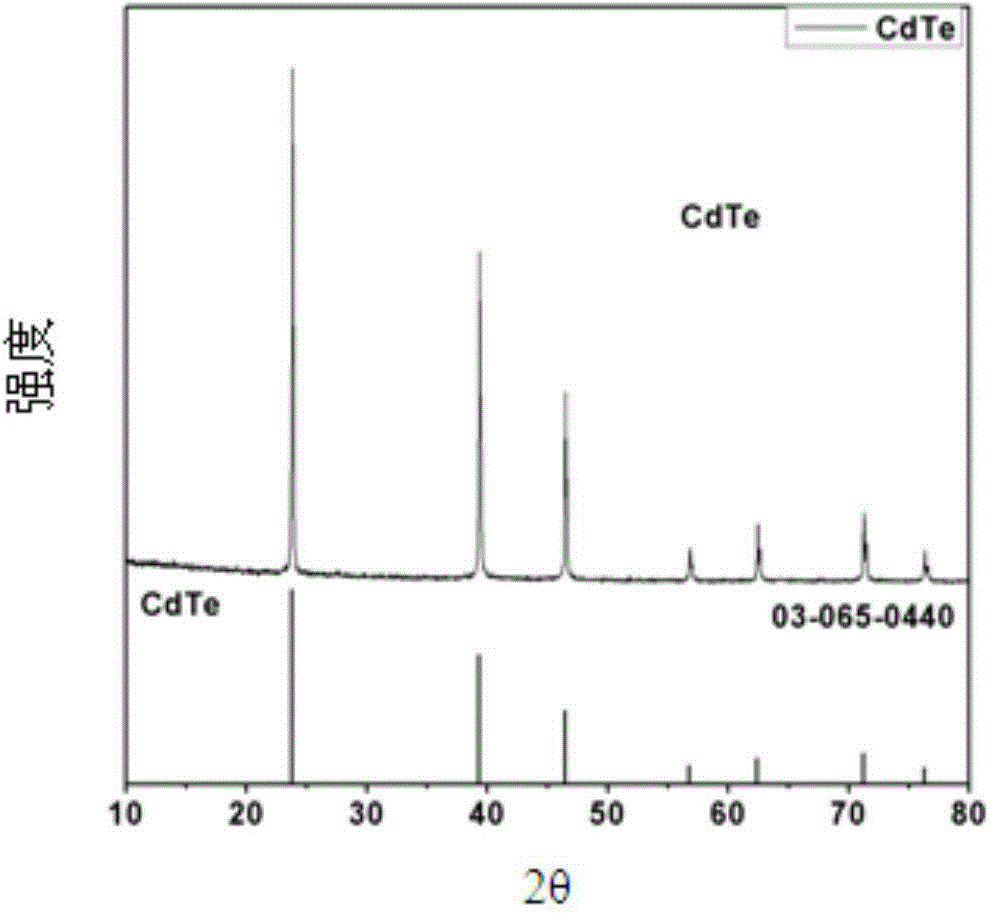

[0029] figure 1 For the X-ray diffraction pattern (XRD) of the cadmium telluride powder that the present embodiment makes, show in the figure: the product powder X-ray characteristic diffraction peak that obt...

Embodiment 2

[0032] A new method for rapidly preparing high-purity cadmium telluride powder materials, which comprises the following steps:

[0033] 1) Mix 5N cadmium powder and 5N tellurium powder at a molar ratio of 1:1, the total mass of the raw materials is 10g, and then grind and mix the raw material powders evenly;

[0034] 2) Press the homogeneously mixed powder obtained in step 1) into a cylindrical block body with a diameter of 12 mm, wherein the pressing process is 4 MPa for 8 minutes;

[0035] 3) The bulk green body obtained in step 2) is ignited at one end to initiate a high-temperature self-propagating synthesis reaction. After the reaction is completed, it is naturally cooled and ground to obtain high-purity cadmium telluride powder.

Embodiment 3

[0037] A new method for rapidly preparing high-purity cadmium telluride powder materials, which comprises the following steps:

[0038] 1) Mix 5N cadmium powder and 5N tellurium powder at a molar ratio of 1:1, the total mass of the raw materials is 20g, and then grind and mix the raw material powders evenly;

[0039] 2) Press the homogeneously mixed powder obtained in step 1) into a cylindrical block body with a diameter of 15 mm, wherein the pressing process is 5 MPa and holding pressure for 2 min;

[0040] 3) The bulk green body obtained in step 2) is ignited at one end to initiate a high-temperature self-propagating synthesis reaction. After the reaction is completed, it is naturally cooled and ground to obtain high-purity cadmium telluride powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com