A kind of equipment for preparing trichlorosilane by cold hydrogenation method

A technology of trichlorosilane and cold hydrogenation, applied in halogenated silicon compounds, halogenated silanes, etc., can solve the problems of large purification workload, affecting reaction efficiency, complicated operating system, etc., to improve the multi-functional integration and simplification of containers Operating procedures, the effect of improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

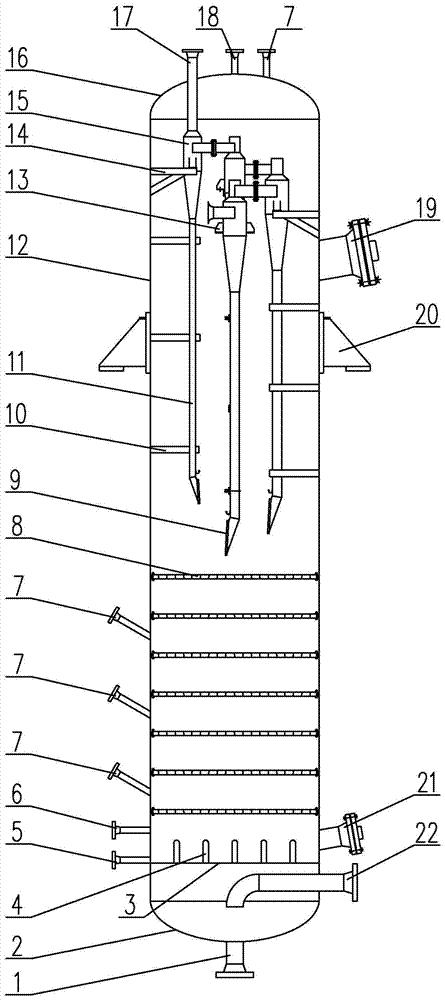

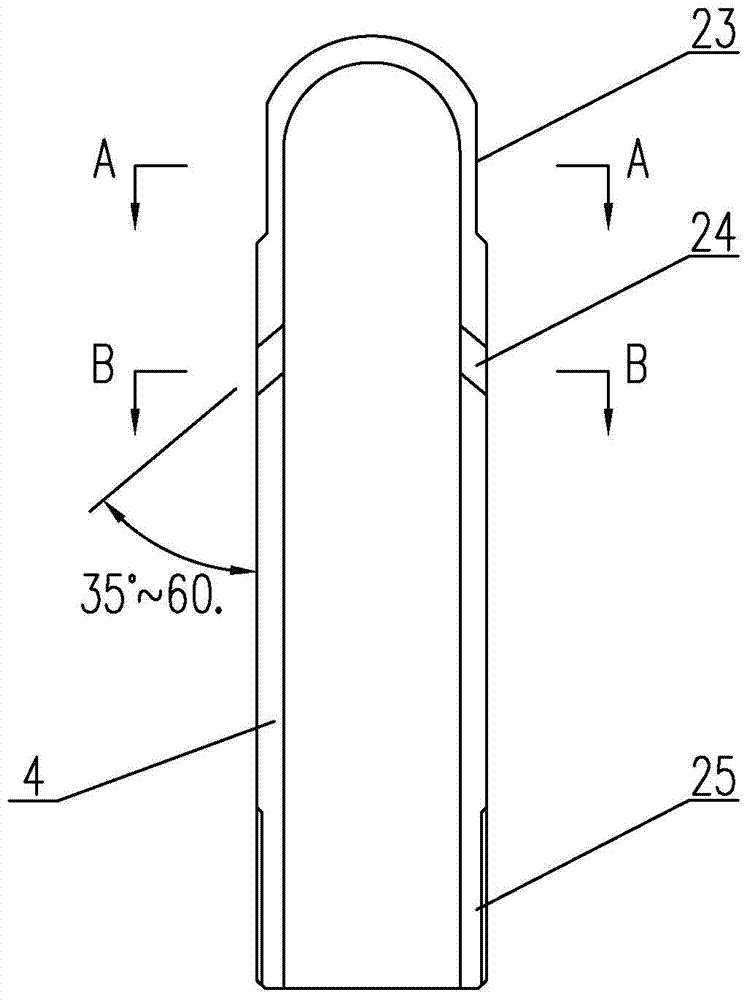

[0036] A kind of equipment for preparing trichlorosilane by cold hydrogenation method, such as figure 1As shown, it includes a vertically arranged cylindrical body 12, the top of the body 12 is provided with an oval upper head 16, the bottom of the body 12 is provided with an oval lower head 2, and the upper head 16 A syngas outlet 17 and a vent port 18 are provided on the top, a residue outlet 1 is provided at the bottom of the lower head 2, and a raw material gas inlet 22 is provided at the lower end of the cylinder wall of the cylinder body 12 close to the lower head 2, and the raw material gas inlet 22 is Extending to the center of the cylinder 12 with the opening facing downward, a distributor support plate 3 is horizontally arranged in the cylinder 12 at the upper position close to the feed gas inlet 22, and several distributor nozzles 4 are evenly distributed on the distributor support plate 3. The injection direction of the nozzle 4 of the cylinder is downward, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com