Concentrated ammonia rectification apparatus for treating titanium dioxide industrial wastewater

A technology for industrial wastewater and concentrated ammonia, applied in the direction of heating water/sewage treatment, etc., can solve the problems of low conversion efficiency of free ammonia nitrogen, inability to achieve degradation effect, high operating costs, etc., achieve small footprint, low treatment cost, and realize separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

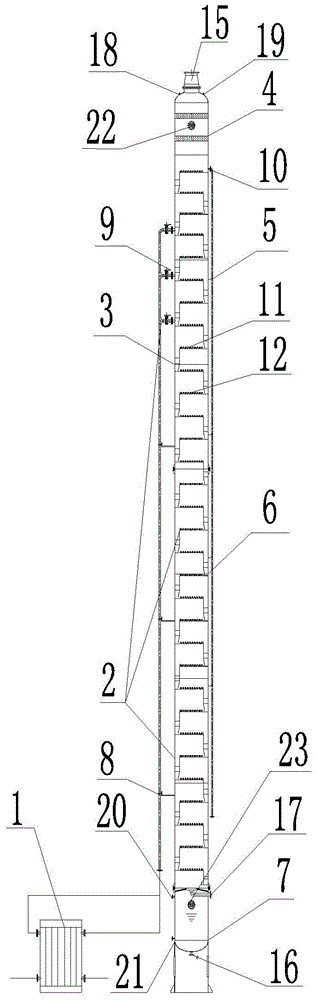

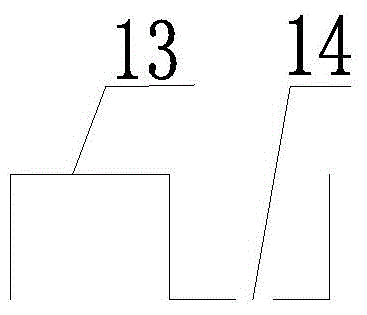

[0025] like figure 1 and figure 2 As shown, a kind of concentrated ammonia rectification device for treating titanium dioxide industrial wastewater according to the present invention includes a preheater 1 and a stripping deamination tower 2, and the stripping deamination tower 2 includes a tower still 3 , the tower kettle 3 is divided into a rectification section 4, a waste water feed section 5, a separation section 6 and a raffinate separation section 7 from top to bottom, and a water inlet pipe 8 is arranged on the outer side of the tower kettle 3, and The upper part of the water inlet pipe 8 is provided with three water inlets 9, and an ammonia reflux pipe 10 is additionally provided on the outer side of the tower kettle 3, and a through-flow tray 11 is provided inside the tower kettle 3, and in the through-flow type A plate-type gas separation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com