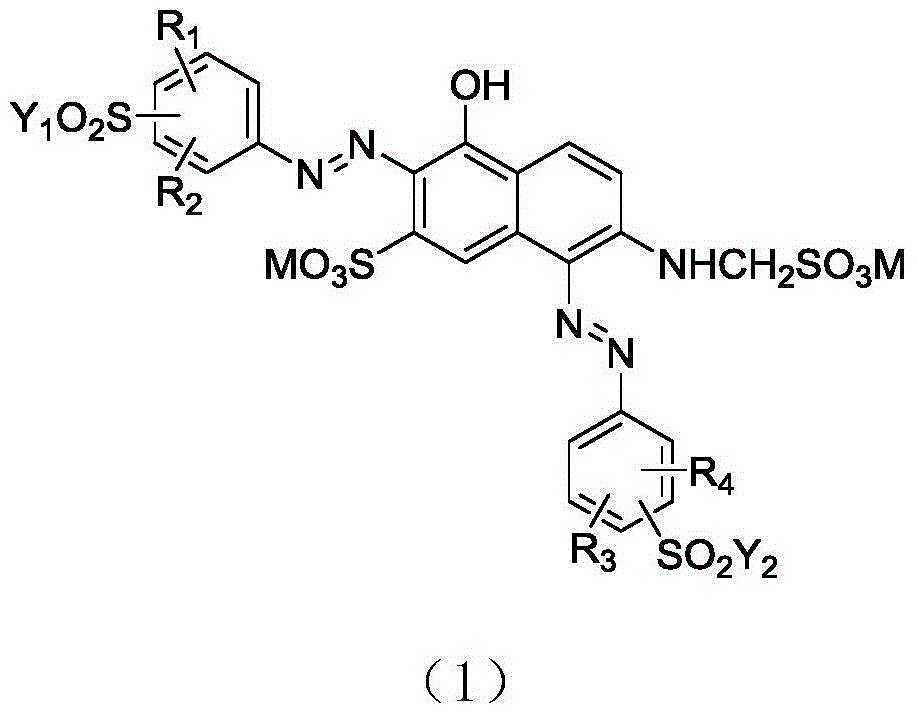

Red reactive dye and preparation method thereof

A reactive dye, red technology, applied in the field of red reactive dyes, can solve the problems of poor rubbing fastness, poor washing fastness, difficult to improve and dye depth, difficult to satisfy customers, etc., to improve rubbing fastness, excellent quality The effect of color synchronization and improved washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

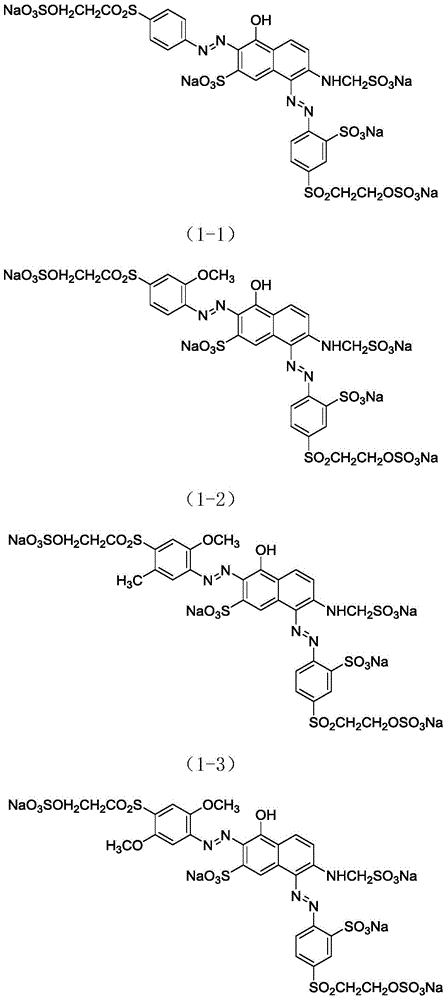

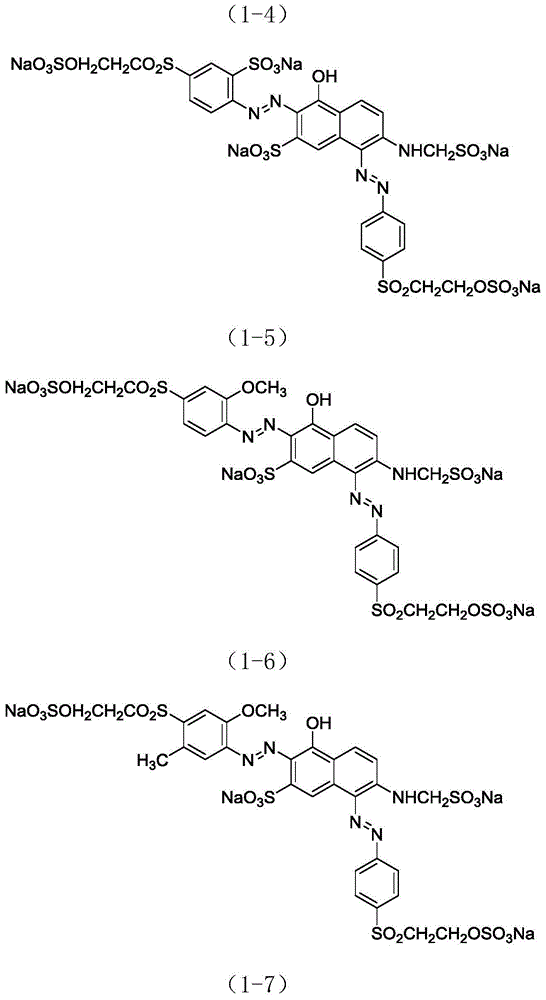

[0064] Embodiment 1: a kind of red reactive dye, is made up of the compound of simple formula (1-1) structure:

[0065]

[0066] (1-1) Its synthetic method step of the compound of structure is as follows:

[0067] 1. Condensation reaction: add 100g of bottom water to the beaker, control the temperature at 25-45°C, add 10g of sodium metabisulfite and stir until completely dissolved, add 9g of formaldehyde solution slowly, measure the pH at 5.0-9.0 after the addition is complete, and then Raise the temperature to 50-70°C, keep the temperature and keep the pH value, and continue stirring for 1-2 hours. The condensation reaction formula is shown in formula (a):

[0068] Na 2 S 2 o 5 +2HCHO+H 2 O→2HOCH 2 SO 3 Na

[0069] Formula (a)

[0070] 2. Sulfomethylation reaction: Cool the above reaction solution to 30-50°C, then add 26g of 2-amino-5-naphthol-7-sulfonic acid, namely J acid, and add 12g of baking soda to raise the pH to 6.0- 8.0, keep warm at 30-50°C and react un...

Embodiment 2

[0080] Embodiment 2: a kind of red reactive dye, is made up of the compound of simple formula (1-2) structure:

[0081]

[0082] (1-2) Its synthetic method step of the compound of structure is as follows:

[0083] 1. Condensation reaction: add 100g of bottom water to the beaker, control the temperature at 25-45°C, add 10g of sodium metabisulfite and stir until completely dissolved, add 9g of formaldehyde solution slowly, measure the pH at 5.0-9.0 after the addition is complete, and then Raise the temperature to 50-70°C, keep the temperature and keep the pH value, and continue stirring for 1-2 hours. The condensation reaction formula is shown in formula (a):

[0084] Na 2 S 2 o 5 +2HCHO+H 2 O→2HOCH 2 SO 3 Na

[0085] Formula (a)

[0086] 2. Sulfomethylation reaction: Cool the above reaction solution to 30-50°C, then add 26g of J acid, add 12g of baking soda to increase the pH to 6.0-8.0, keep warm at 30-50°C until the residue of J acid liquid phase is ≤2.0 % is the...

Embodiment 3

[0096] Embodiment 3: a kind of red reactive dye, is made up of the compound of simple formula (1-3) structure:

[0097]

[0098] (1-3) Its synthetic method step of the compound of structure is as follows:

[0099] 1. Condensation reaction: add 100g of bottom water to the beaker, control the temperature at 25-45°C, add 10g of sodium metabisulfite and stir until completely dissolved, add 9g of formaldehyde solution slowly, measure the pH at 5.0-9.0 after the addition is complete, and then Raise the temperature to 50-70°C, keep the temperature and keep the PH value, and continue to stir and react for 1-2 hours. The condensation reaction formula is shown in formula (a):

[0100] Na 2 S 2 O5+ 2 HCHO+H 2 O→2HOCH 2 SO 3 Na

[0101] Formula (a)

[0102] 2. Sulfomethylation reaction: Cool the above reaction solution to 30-50°C, then add 26g of J acid, add 12g of baking soda to raise the pH to 6.0-8.0, keep warm at 30-50°C until the residue of J acid liquid phase is ≤2.0 % ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com