Powder coating for polypropylene sanitary product, preparation method and application

A technology for bathroom products and powder coatings, applied in powder coatings, epoxy resin coatings, coatings, etc., can solve the problems of undiscovered patent publications, etc., and achieve high value, chemical resistance, and high safety and hygiene. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

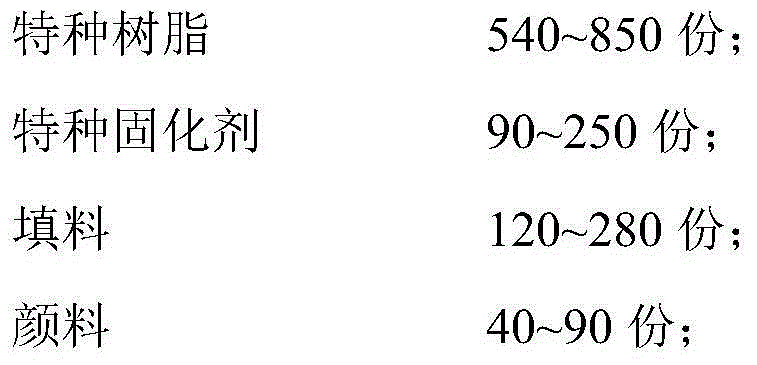

[0032] A powder coating for polypropylene sanitary products, its raw material components and parts by weight are respectively:

[0033]

[0034] The weight ratio of the booster, the leveling agent, the anti-interference agent and the degassing agent in the auxiliary agent is 5-9:10-14:9-16:6-11.

[0035] The steps of the above-mentioned preparation method for the powder coating of polypropylene sanitary products are as follows:

[0036] Add the above-mentioned materials to the high-speed mixer according to the parts by weight, and then add them to the extruder after dry mixing, and perform conventional melting, mixing, cooling, tableting at the extrusion temperature of 80-90 ° C, and then pass through the pulverizer Crushing, grading, sieving, and packaging, it becomes the finished powder coating.

[0037] The coating effect of the above powder coating is as follows: figure 1 shown.

Embodiment 2

[0039] A powder coating for polypropylene sanitary products, its raw material components and parts by weight are respectively:

[0040]

[0041] The steps of the preparation method of the above-mentioned special decorative and protective powder coating are the same as in Example 1.

Embodiment 3

[0043] A powder coating for polypropylene sanitary products, its raw material components and parts by weight are respectively:

[0044]

[0045] The steps of the preparation method of the above-mentioned special decorative and protective powder coating are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com