Optical assembly for being vertically coupled with photoelectric transceiving array and manufacturing method

An optical component, photoelectric transceiver technology, applied in optical components, optical waveguide coupling, optics, etc., can solve the problems of easy damage, unusability, and fiber breakage of optical fibers, and achieve high pass rate, high reflection accuracy, and easy processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

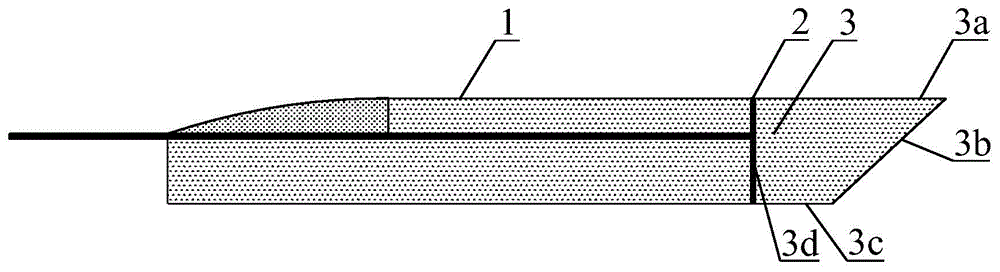

[0037] see figure 1 As shown, Embodiment 1 provides an optical assembly for vertical coupling with an optoelectronic transceiver array, the optical assembly includes a multi-core optical fiber array 1 and a reflective prism 3 . The reflective prism 3 is a right-angled trapezoidal prism, which includes an upper bottom surface 3c, a lower bottom surface 3a, a right-angled waist surface 3d and an oblique waist surface 3b, and the angle between the oblique waist surface 3b and the lower bottom surface 3a is 41°~45°, and the right-angle waist surface The height of the surface 3d is equal to the height of the multi-core optical fiber array 1, and is connected to the multi-core optical fiber array 1 by an adhesive 2. The right-angled trapezoidal prism can be set upright or upside down. In this embodiment, the right-angled trapezoidal prism is set upside down. .

[0038] Adhesive 2 is shadowless glue, such as acrylate. The adhesive 2, the reflective prism 3 and the multi-core optica...

Embodiment 2

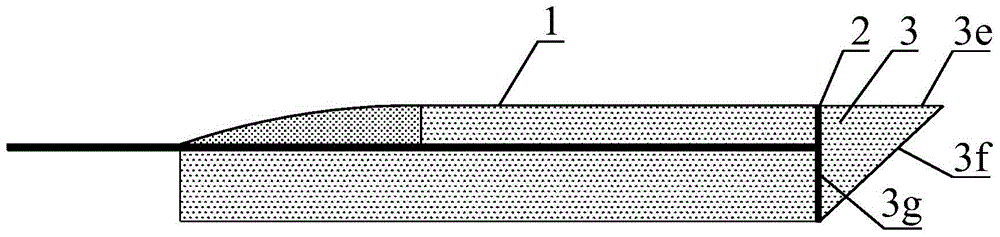

[0046] see figure 2 As shown, Embodiment 2 provides an optical assembly for vertical coupling with a photoelectric transceiver array, the optical assembly includes a multi-core optical fiber array 1 and a reflective prism 3 . Reflecting prism 3 is a right-angled triangular prism, which includes a first right-angled surface 3e, a second right-angled surface 3g and an inclined surface 3f, the angle between the first right-angled surface 3e and the inclined-plane 3f is 41°~45°, and the second right-angled surface 3g The height is equal to the height of the multi-core optical fiber array 1, and is connected to the multi-core optical fiber array 1 through the adhesive 2, the first rectangular surface 3e can be located above the slope 3f, and can also be located above the slope 3f, in this embodiment, The first right-angled surface 3e is located above the inclined surface 3f.

[0047] Adhesive 2 is shadowless glue, such as acrylate. The adhesive 2, the reflective prism 3 and the ...

Embodiment 3

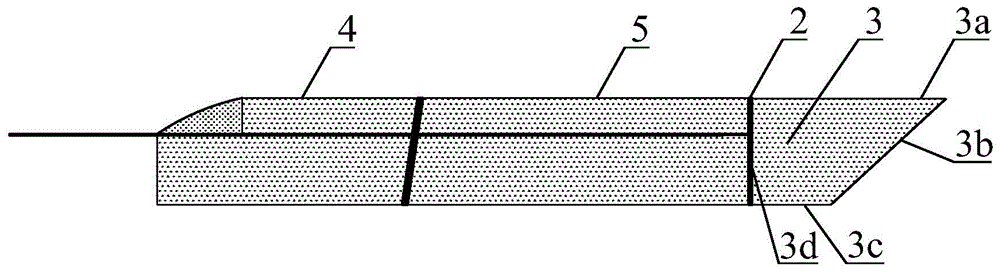

[0055] see image 3 As shown, Embodiment 3 provides an optical assembly for vertical coupling with an optoelectronic transceiver array, the optical assembly includes an arrayed waveguide grating chip 5 and a reflective prism 3 . The reflective prism 3 is a right-angled trapezoidal prism, which includes an upper bottom surface 3c, a lower bottom surface 3a, a right-angled waist surface 3d and an oblique waist surface 3b, and the angle between the oblique waist surface 3b and the lower bottom surface 3a is 41°~45°, and the right-angle waist surface The height of the surface 3d is equal to the height of the arrayed waveguide grating chip 5, and is connected to the arrayed waveguide grating chip 5 through the adhesive 2. The right-angled trapezoidal prism can be set upright or upside down. In this embodiment, the right-angled trapezoidal prism is set upside down. .

[0056] Adhesive 2 is shadowless glue, such as acrylate. In this embodiment, the arrayed waveguide grating chip 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com