Preparation method of platinum-palladium nano-alloy anode material for high-performance ethanol catalysis

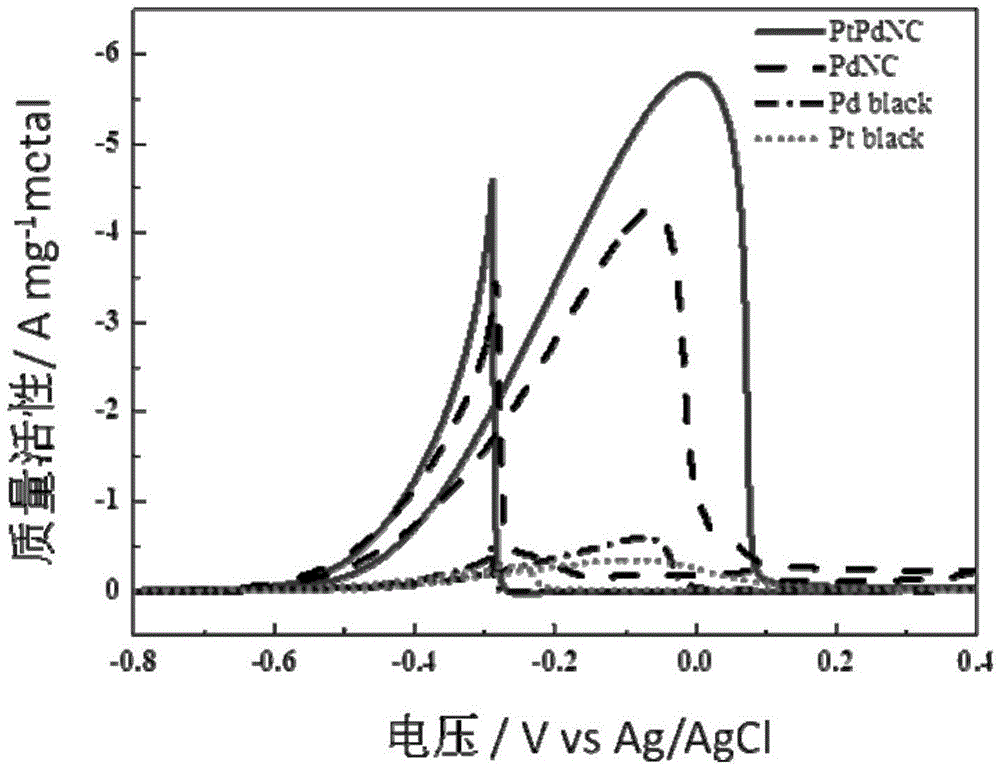

A nano-alloy and anode material technology, applied in battery electrodes, electrical components, circuits, etc., to achieve the effects of large electroactive surface area, high preparation repeatability, high catalytic performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

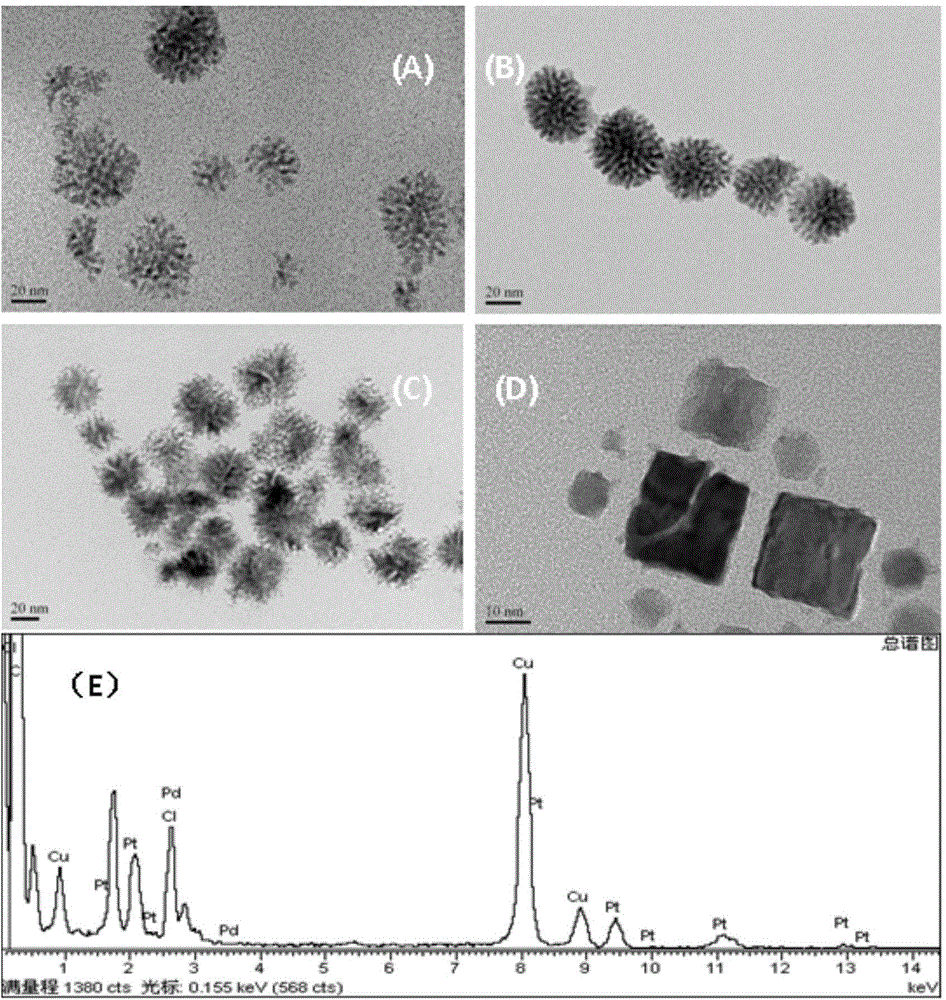

[0028] The preparation method of the platinum-palladium nano-alloy anode material of high-performance catalysis ethanol comprises the following steps:

[0029] (1) Add 30mg cetylpyridinium chloride into 10mL ultrapure water and stir thoroughly, then mix sodium tetrachloropalladate and chloroplatinic acid at 10mM-20mM 1:1 volume into the above solution, add dropwise 0.1 600 μL of mol / L ascorbic acid was kept at a certain temperature, and allowed to stand for 4 hours for complete reaction to obtain a platinum-palladium nanoparticle sol stabilized by cetylpyridine chloride micelles. During the reaction process, the color of the sol was initially light brownish yellow and slowly changed to black.

[0030] (2) Cool the prepared sol at room temperature, centrifuge at 10000-20000 rpm for 10 min, wash with water several times to remove excess cetylpyridinium chloride, and set the volume to 1 mL.

[0031] (3) After polishing, the glassy carbon electrode surface (7mm 2 ), drop-coat 10...

Embodiment 2

[0036] The preparation method of the platinum-palladium nano-alloy anode material of high-performance catalysis ethanol comprises the following steps:

[0037] (1) Sodium tetrachloropalladate (concentration is 10mM) and chloroplatinic acid (concentration is 10mM) are added in the aqueous solution of cetylpyridinium chloride (concentration is 5mM), adds ascorbic acid (concentration is 0.05M), and The molar ratio of sodium tetrachloropalladate, chloroplatinic acid, chlorohexadecylpyridine, and ascorbic acid is 3:3:60:60, keep the temperature at 10°C, and leave it for 6 hours to obtain hexadecyl chloride Pyridine micelles stabilized platinum-palladium nanoparticle sol, and the synthesis of platinum-palladium nanoparticles with different shapes was regulated by different temperatures. During the reaction process, the color of the sol was initially light brownish yellow and slowly changed to black.

[0038](2) Cool the platinum palladium nanoparticle sol stabilized by cetylpyridin...

Embodiment 3

[0042] The preparation method of the platinum-palladium nano-alloy anode material of high-performance catalysis ethanol comprises the following steps:

[0043] (1) Sodium tetrachloropalladate (concentration is 20mM) and chloroplatinic acid (concentration is 20mM) are added in the aqueous solution of cetylpyridinium chloride (concentration is 10mM), adds ascorbic acid (concentration is 0.1M), and The molar ratio of sodium tetrachloropalladate, chloroplatinic acid, chlorohexadecylpyridine, and ascorbic acid is 3:3:90:60, and the temperature is maintained at 100°C, and left standing for 3 hours to obtain hexadecyl chloride Pyridine micelles stabilized platinum-palladium nanoparticle sol, and the synthesis of platinum-palladium nanoparticles with different shapes was regulated by different temperatures. During the reaction process, the color of the sol was initially light brownish yellow and slowly changed to black.

[0044] (2) Cool the platinum-palladium nanoparticle sol stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com