Rechargeable aluminum ion fused salt battery and preparation method thereof

A molten salt battery, aluminum ion technology, applied in secondary batteries, sustainable manufacturing/processing, circuits, etc., can solve problems such as potential safety hazards, and achieve the effect of reducing production costs, reducing internal resistance, and cheap prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

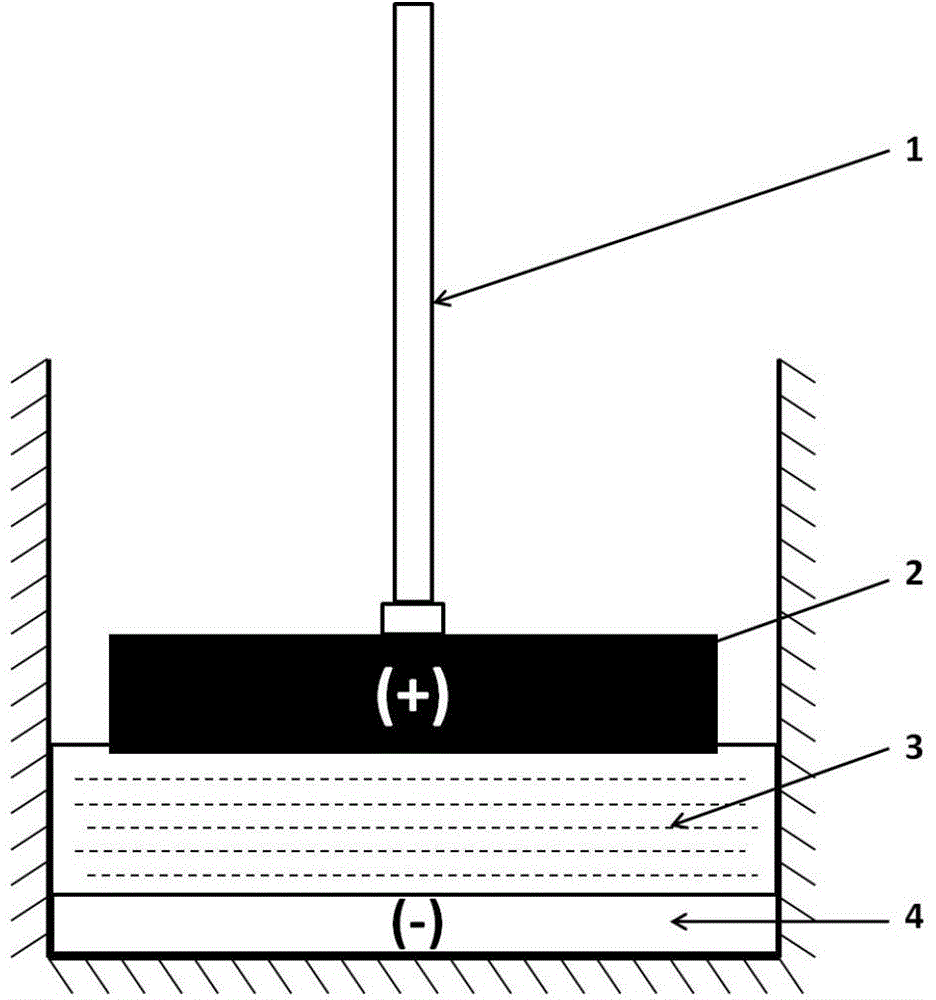

[0028] Take a graphite block with a purity of more than 99% and process it into a circular block with a diameter of 1000mm and a thickness of 200mm, and process a thread with a depth of 100mm and a diameter of 100mm at the center of the cross-section of the chip, and connect by thread A stainless steel rod with a diameter of 60mm was used as the conductive rod of the anode graphite. A cylindrical electrolytic cell with an inner diameter of 1200mm and a depth of 1000mm is built as a reaction vessel with conductive bottom and sidewalls insulated. Under the protection of an inert atmosphere, an aluminum ingot with a purity greater than 99% is selected and pre-melted at the bottom of the reaction vessel to form a cylindrical-like aluminum ingot with a thickness of about 100 mm covering the entire bottom of the reaction vessel. Equimolar NaF and KF were used as supporting electrolytes, and 10% Na was added 3 AlF 6 to provide aluminum ions. When assembling the battery, a uniforml...

Embodiment 2

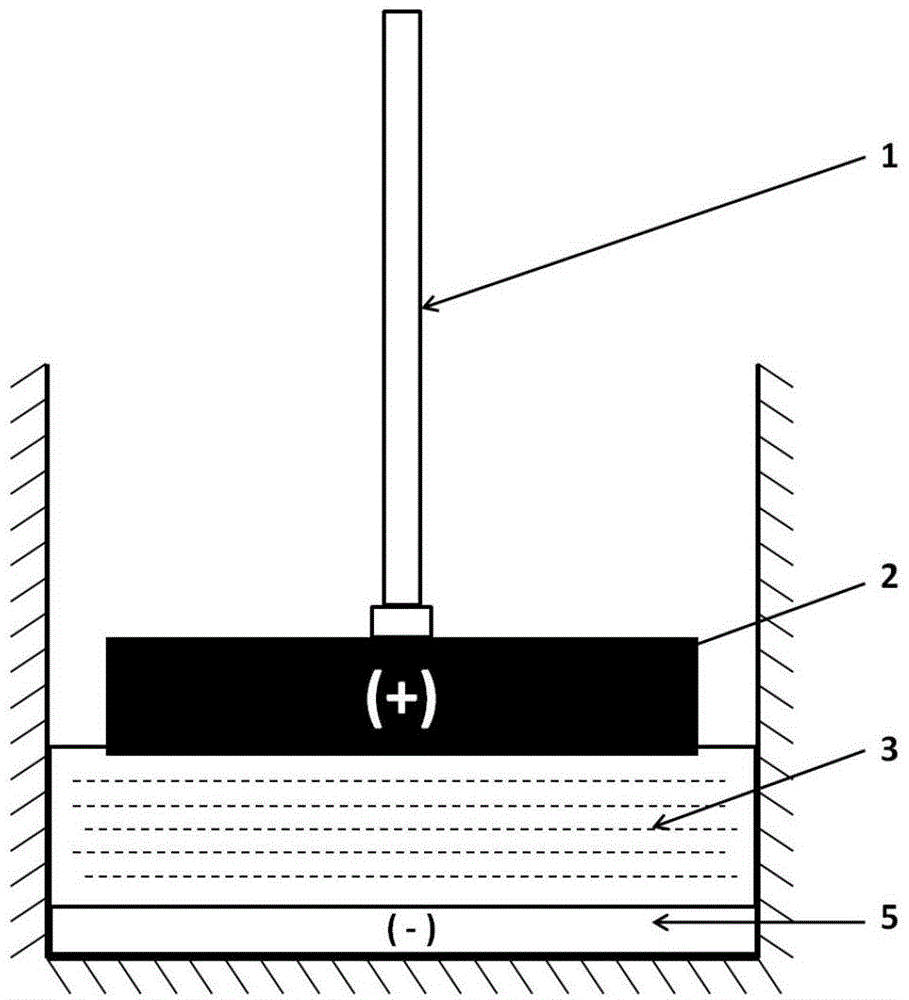

[0030] Take a graphite block with a purity of more than 99%, and process it into a square block with a side length of 1000mm and a height of 200mm, and process a thread with a depth of 100mm and a diameter of 100mm at the center of the cross-section of the chip. Connect a stainless steel rod with a diameter of 60mm as the conductive rod of the positive graphite. A rectangular parallelepiped electrolytic cell with a side length of 1200mm and a depth of 1000mm in masonry is conductive and the sidewall is insulated as a reaction vessel. Under the protection of an inert atmosphere, a copper-aluminum ingot is selected and pre-melted at the bottom of the reaction vessel to form a cylindrical-like copper-aluminum alloy ingot with a thickness of about 60 mm covering the entire bottom of the reaction vessel. Using equimolar LiF and KF as supporting electrolyte, and adding 8% AlCl 3 to provide aluminum ions. When assembling the battery, a uniformly mixed electrolyte was added to the r...

Embodiment 3

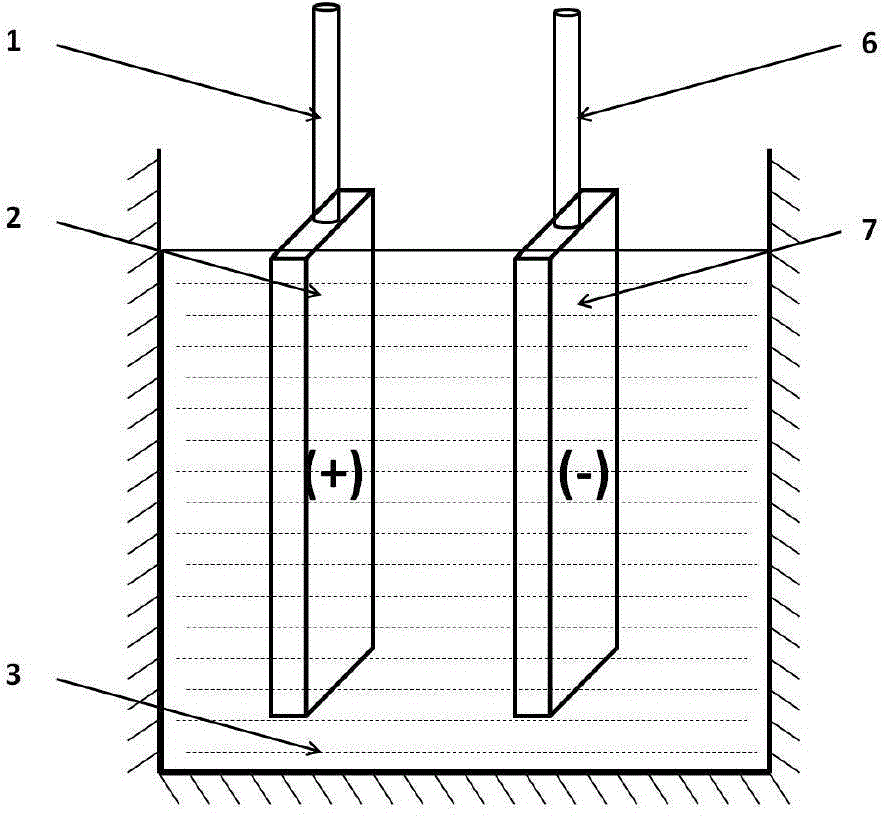

[0032] The graphite block with a purity of more than 90% is processed into a square block with a side length of 1000mm and a thickness of 100mm, and a thread with a depth of 200mm and a diameter of 60mm is machined on one side of the sheet, and a stainless steel with a diameter of 60mm is connected by the thread. The rods act as conductive rods for the anode graphite. A cubic electrolytic cell with a side length of 1200mm and a depth of 1200mm was built as a reaction vessel. Select an aluminum ingot with a purity greater than 99%, process it into a square sheet with a side length of 1000mm and a thickness of 50mm, and process a thread with a depth of 100mm and a diameter of 30mm on one side of the sheet, and connect a stainless steel with a diameter of 30mm through the thread. The rod acts as the conductive rod of the negative aluminum sheet. In equimolar CaCl 2 and LiCl as supporting electrolyte, and add 8% AlF 3 to provide aluminum ions. When assembling the battery, a unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com