Concentrator photovoltaic conversion device and manufacturing method thereof

A photoelectric conversion device and manufacturing method technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., capable of solving problems such as inability to obtain power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

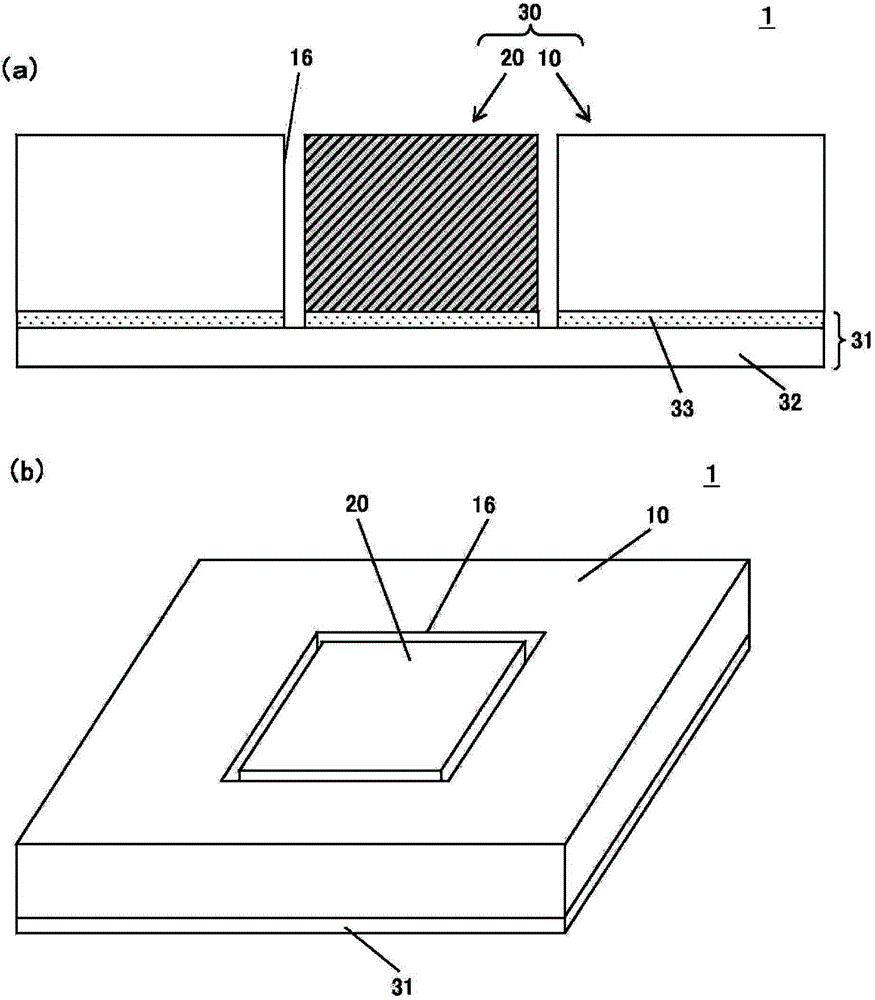

Embodiment 1

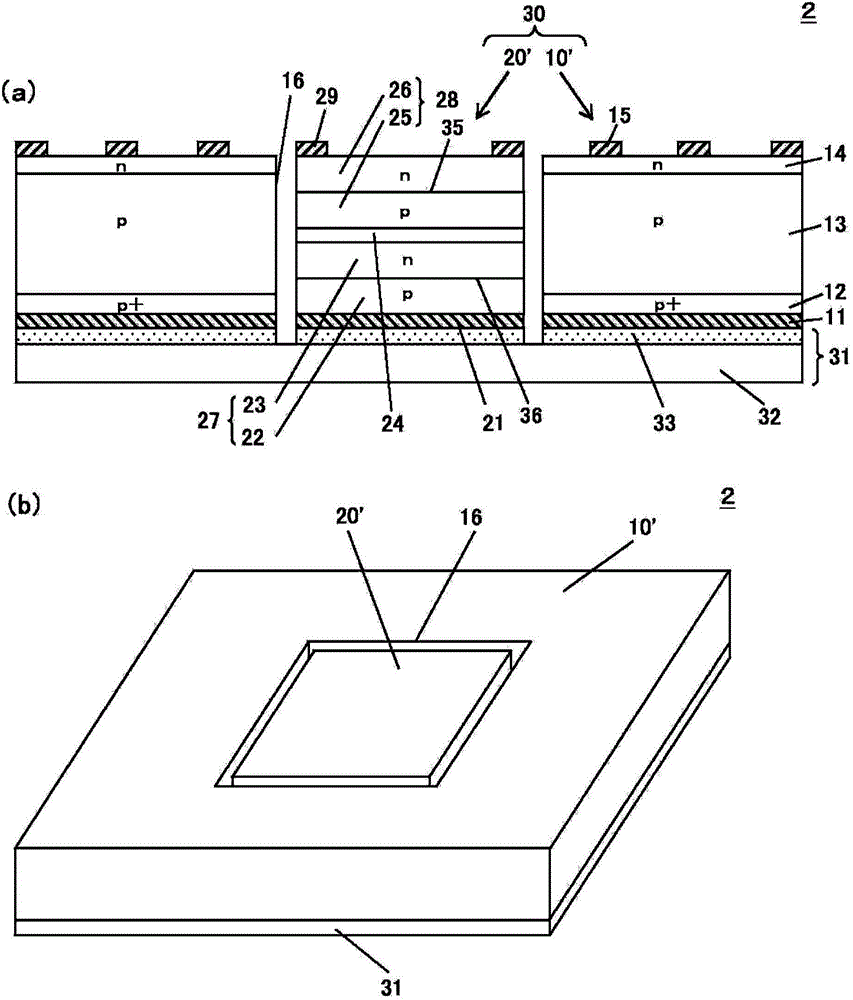

[0201] First, a silicon solar cell 10' having through holes 16 formed by an etching method is prepared.

[0202] Next, using solder paste, the silicon solar cell 10' and the III-V group multi-junction solar cell 20' are placed on the external connection substrate 31, that is, the PCB substrate. The III-V group multi-junction solar cell 20' is mounted It is placed in the through hole 16 part of the silicon solar cell 10'.

[0203] Next, UV ozone treatment is applied.

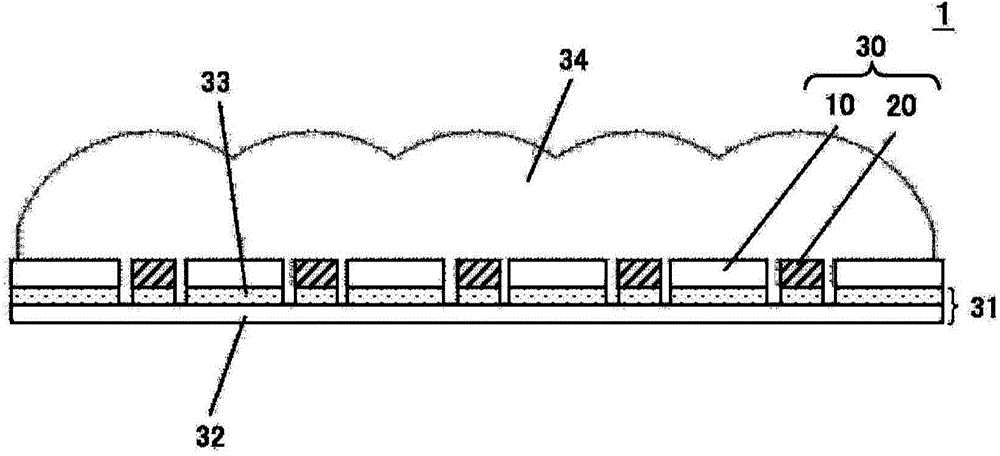

[0204] Next, the photoelectric conversion element 30 and the external connection substrate 31 are placed in a mold, and a silicone resin (LPS-3541 (model): manufactured by Shin-Etsu Chemical Co., Ltd.) is compression molded to form The condenser lens 34 is integrally molded to manufacture the condenser type photoelectric conversion device 2.

Embodiment 2

[0206] First, a silicon solar cell 10' having through holes 16 formed by an etching method is prepared.

[0207] Next, using solder paste, the silicon solar cell 10' and the III-V group multi-junction solar cell 20' are placed on the external connection substrate 31, that is, the PCB substrate. The III-V group multi-junction solar cell 20' is mounted It is placed in the through hole 16 part of the silicon solar cell 10'.

[0208] Next, UV ozone treatment is performed.

[0209] Next, using a vacuum laminating device (manufactured by Nichigo-Morton), a resin film made by mixing silicone resin (AF-500 (model): manufactured by Shin-Etsu Chemical Industry) and phosphor is attached to the silicon solar cell 10' s surface.

[0210] Next, the photoelectric conversion element 30 connected to the external connection substrate 31 is placed in a mold, and a silicone resin (LPS-3541 (model): manufactured by Shin-Etsu Chemical Co., Ltd.) is compression molded to integrally mold the condenser 34 to...

Embodiment 3

[0212] First, a silicon solar cell 10' having through holes 16 formed by an etching method is prepared.

[0213] Next, using solder paste, the silicon solar cell 10' and the III-V group multi-junction solar cell 20' are placed on the external connection substrate 31, that is, the PCB substrate. The III-V group multi-junction solar cell 20' is mounted It is placed in the through hole 16 part of the silicon solar cell 10'.

[0214] Next, UV ozone treatment is performed.

[0215] Next, by spin coating, the surface of the silicon solar cell 10' is coated with a mixture of polysilazane and phosphor, and then cured to form a vitreous layer.

[0216] Next, the photoelectric conversion element 30 connected to the external connection substrate 31 is placed in a mold, and a silicone resin (LPS-3541 (model): manufactured by Shin-Etsu Chemical Co., Ltd.) is compression molded to integrally mold the condenser 34 to produce a poly Light-type photoelectric conversion device 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com