Composite carrier-supported cobalt-based Fischer-Tropsch synthesis catalyst, and preparation method and application thereof

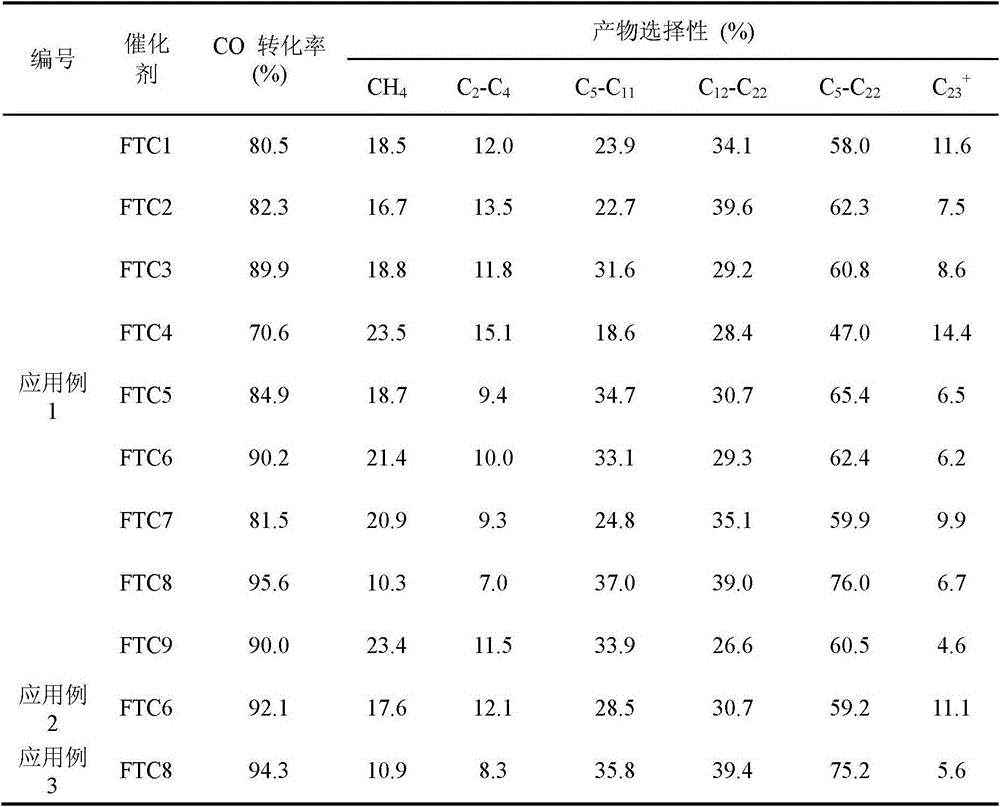

A composite carrier and Fischer-Tropsch synthesis technology, which is applied in the preparation of liquid hydrocarbon mixtures, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of high selectivity of heavy hydrocarbons, low selectivity of methane to CO conversion, and complex catalyst preparation process problems such as low CH4 and CO2 selectivity and high CO conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] 1) Preparation of composite carrier: For example, one or more commercially purchased USY, ZSM-5, MCM-22, HY or beta zeolite molecular sieves are formulated into slurry, and then the ordered mesoporous material TiO 2 , SBA-15, SiC or ZrO 2 One or more of them are added to the slurry, and subjected to ultrasonic treatment for 0.5-10 hours, for example, ultrasonic vibration for 4 hours, to obtain the composite carrier.

[0025] 2) Introduction of additives: one or more soluble salt solutions of Ni, Mn, Zr, La, Ce, Ca or Re such as nitrate aqueous solution, for example, using the method of equal volume impregnation, equal volume impregnation to the step 1) on the composite carrier prepared, then dried and calcined. For example, dry at 100-120°C for 12-36h, such as 12h; bake at a temperature of 300-600°C for 2-8h, for example, bake at 400-600°C for 4-6h;

[0026]3) Introduction of active component cobalt: impregnating an equal volume of cobalt salt solution onto the compos...

preparation example 1

[0037] Weigh 2g of commercially purchased USY zeolite molecular sieve sieved to below 200 mesh and dissolve it in 15mL of absolute ethanol solution, stir at a constant speed with a magnetic stirrer for 2-4h to prepare a slurry, and then slowly add 18g of purchased USY zeolite to the slurry and grind to Mesoporous material ZrO below 200 mesh 2 , using a dual-frequency numerically controlled ultrasonic reactor to ultrasonically vibrate for 4 hours to form a homogeneous mixture of the two materials. Then dry it in an oven at 110°C for 12 hours and take it out. Weigh 1.3g of purchased analytically pure Ca (NO 3 ) 2 4H 2 The O powder was formulated into an aqueous solution, impregnated with an equal volume on the above-mentioned dried composite carrier, dried at 120°C for 12h, and baked in a muffle furnace at 400°C for 4h before taking it out. The analytically pure Co(NO 3 ) 2 ·6H 2 The O powder was formulated into an aqueous solution, impregnated with an equal volume on the...

preparation example 2

[0039] The process is the same as in Preparation Example 1, except that 2 g of USY zeolite molecular sieve is replaced by 2 g of ZSM-5 zeolite molecular sieve to obtain cobalt-based Fischer-Tropsch synthesis catalyst FTC2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com