A kind of modification method of graphene oxide

A graphene and graphene dispersion technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as no verification of water reducing agent, and achieve the effect of uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for graphene oxide modification, comprising the steps of:

[0029] Step 1, the preparation of graphene oxide:

[0030] Add 1 g of graphite powder into a three-necked flask, add 23ml of 98% wt concentrated sulfuric acid, stir in an ice-water bath at 0°C for 15mins; add 1g of NaNO to the mixed solution 3 (purity ≥ 99.0%), slowly add 3g of potassium permanganate (purity ≥ 99.5%) after reacting for 20 mins, continue stirring for 40 mins; then raise the temperature to 35°C for 2 hrs, slowly add 70 ml of deionized water, and finally add 3 ml 30% hydrogen peroxide, after the solution is cooled and reacted completely, the product is centrifuged and washed to obtain graphene oxide;

[0031] Step 2, modification of graphene oxide:

[0032] Dissolve the graphene oxide sol with an ultrasonic cleaner for 1 h to obtain a light brown graphene oxide dispersion with a concentration of 2 mg / ml; take 30 ml of the solution and place it in a water bath at 80°C, and slowly drop it...

Embodiment 2

[0035] A method for graphene oxide modification, comprising the steps of:

[0036] Step 1 is the same as embodiment 1;

[0037] Step 2, modification of graphene oxide:

[0038] Dissolve the graphene oxide sol with an ultrasonic cleaner for 1 h to obtain a light brown graphene oxide dispersion with a concentration of 1 mg / ml; take 50 ml of the solution and place it in a water bath at 70°C, and slowly drop it under stirring. Add 2 g of polycarboxylate superplasticizer with a mass fraction of 20%, react for 30 mins, and then ultrasonicate for 1 h to obtain modified graphene oxide.

[0039] The modified graphene oxide obtained in Example 2 was dropped into a saturated calcium hydroxide solution, and slightly oscillated, but no coagulation phenomenon occurred, indicating that the modification was successful.

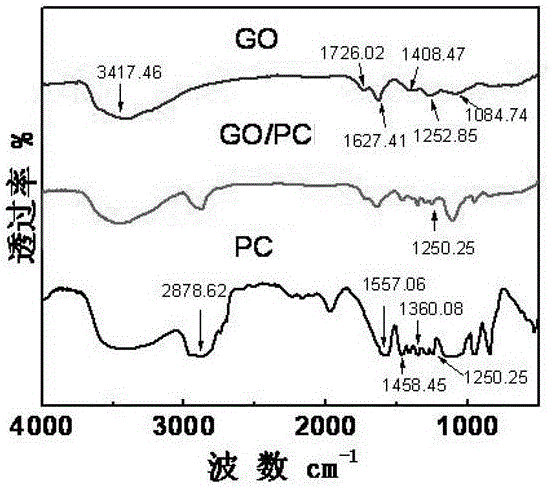

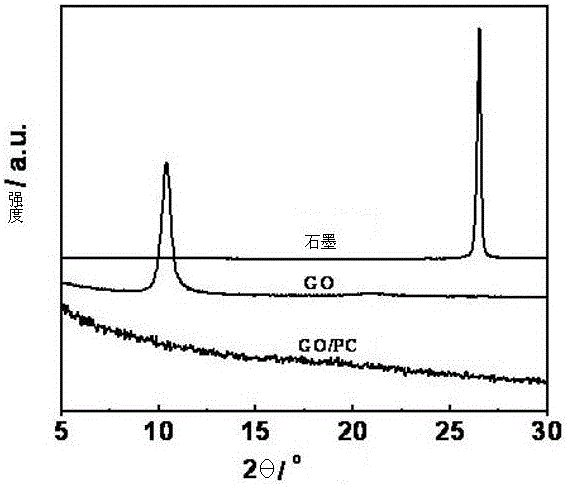

[0040] figure 1 Infrared spectrograms before and after modification of modified graphene oxide in Example 1 and infrared spectrograms of polycarboxylate superplasticizer (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com