Aerobic granular sludge system construction and operation method for treating culture biogas slurry

A technology of aerobic granular sludge and biogas slurry, which is applied in sustainable biological treatment, chemical instruments and methods, animal husbandry wastewater treatment, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

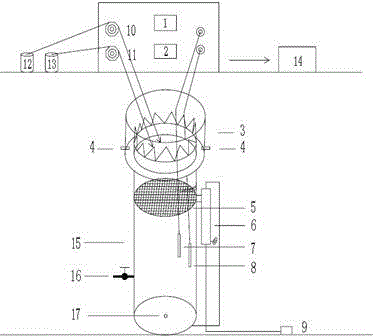

[0020] Such as figure 1 As shown, when constructing the aerobic granular sludge system, the water is introduced into the zigzag water tank (3) through the water inlet pipe (4). It flows into the reactor (15), and washes the inner wall of the reactor (15) while slowly flowing along the wall; the aerobic granular sludge system senses the pH in the solution through the pH electrode (7) during the process of treating the biogas slurry. The pH value is monitored in real time by the pH controller (1); when the pH value exceeds the set range, the computer (14) controls the peristaltic pump-acid (10) and peristaltic pump-base (11) to automatically feed the acid solution ( 12) or alkaline solution (13) to adjust the pH; feel the dissolved oxygen in the solution through the dissolved oxygen electrode (8), display its value through the dissolved oxygen detector (2), and pass the glass rotameter (6) to control the aeration volume range of the aeration equipment (17), the dissolved oxygen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com