Ammonium sulfate-polyglutamic acid slow-release fertilizer and preparation method thereof

A technology of polyglutamic acid and ammonium sulfate, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as high grain and vegetable sales prices, reduced marginal efficiency of chemical fertilizers and pesticides, stagnant crop production, etc., to improve agricultural products Mass, Utilization Increased, Unbreakable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

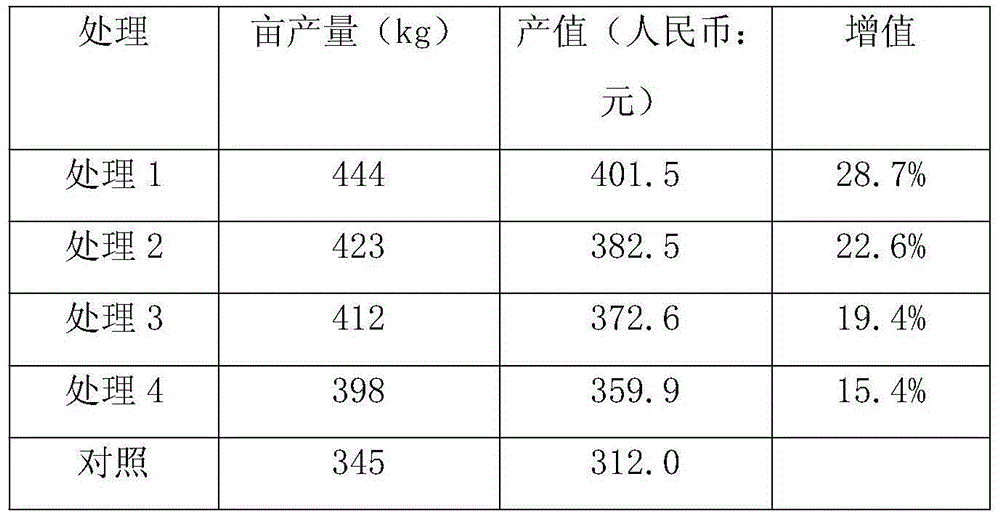

Examples

Embodiment 1

[0030] Ammonium sulfate-polyglutamic acid slow-release fertilizer of the present invention comprises the composition of following weight:

[0031] Ammonium sulfate 46000kg Potassium dihydrogen phosphate 11000kg

[0032] Potassium chloride 16000kg polyglutamic acid 0.6kg.

[0033] The preparation method of ammonium sulfate-polyglutamic acid slow-release fertilizer of the present invention comprises the following steps:

[0034] 46,000kg of ammonium sulfate, 11,000kg of potassium dihydrogen phosphate and 16,000kg of potassium chloride were pulverized and mixed uniformly to obtain a mixture, and 0.6kg of polyglutamic acid was added to the mixture, and the mixture was fully mixed to obtain a base material. The base material is pulverized by a chain crusher and transported to the drum granulator for granulation. The drum speed is controlled at 15rpm and the inclination is 15°. At the same time, water with 8% of the base material mass is added, and the material from the granulator ...

Embodiment 2

[0037] Ammonium sulfate-polyglutamic acid slow-release fertilizer of the present invention comprises the composition of following weight:

[0038] Ammonium sulfate 50000kg Potassium dihydrogen phosphate 13000kg

[0039] Potassium chloride 18000kg polyglutamic acid 0.8kg.

[0040] 50,000kg of ammonium sulfate, 13,000kg of potassium dihydrogen phosphate and 18,000kg of potassium chloride were pulverized and mixed uniformly, and 0.8kg of polyglutamic acid was added, and mixed thoroughly to obtain the base material. The base material is pulverized by a chain crusher and transported to the drum granulator for granulation. The drum speed is controlled at 16rpm and the inclination is 15°. At the same time, water with 7% of the base material mass is added, and the material from the granulator is transported to the drum dryer. Dryer, control the combustion of the hot air stove so that the temperature at the front of the drum dryer is 80°C and the temperature at the tail is 60°C. The ...

Embodiment 3

[0043] Ammonium sulfate-polyglutamic acid slow-release fertilizer of the present invention comprises the composition of following weight:

[0044] Ammonium sulfate 53000kg Potassium dihydrogen phosphate 15000kg

[0045] Potassium chloride 25000kg polyglutamic acid 1.2kg.

[0046] 53000kg of ammonium sulfate, 15000kg of potassium dihydrogen phosphate and 25000kg of potassium chloride were respectively pulverized and then mixed uniformly, 1.2kg of polyglutamic acid was added, and fully mixed to obtain the base material. The base material is pulverized by a chain crusher and transported to the drum granulator for granulation. The drum speed is controlled at 15rpm and the inclination is 17°. At the same time, water with 9% of the base material mass is added, and the material from the granulator is transported to the drum dryer. Dryer, control the combustion of the hot air stove so that the temperature at the front of the drum dryer is 80°C and the temperature at the tail is 60°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com