Method for preparing high-purity 4-(2-hydroxyerhyl) piperazine-1-erhaesulfonic acid through nanofiltration

A technology of hydroxyethylpiperazineethanesulfonic acid and hydroxyethylpiperazine, which is applied in the field of organic matter preparation, can solve the problems of high salt content in wastewater, small treatment capacity, environmental pollution, etc., and achieve simple operation process and environmental protection in the production process , The effect of low purification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

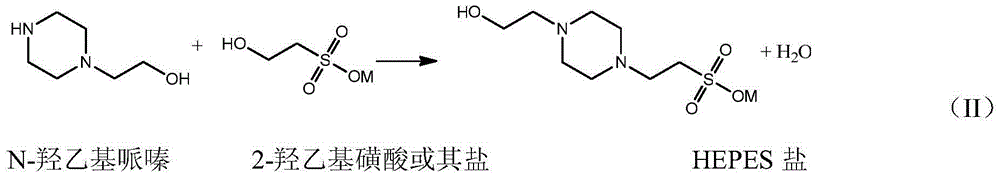

[0030] Add 0.5mol N-hydroxyethylpiperazine, 0.525mol sodium 2-isethionate and 500mL deionized water into a 1000mL four-necked flask with a reflux tube, and carry out condensation reaction under full stirring; React for 1.0 hour, then gradually increase the temperature and boil to reflux, and continue to react for 2.0 hours; then lower the temperature to obtain a reaction mother liquor containing sodium 4-hydroxyethylpiperazineethanesulfonate. Through high-performance liquid chromatography analysis, the calculated yield of sodium 4-hydroxyethylpiperazineethanesulfonate was 88.4%.

Embodiment 2

[0032] Add 0.5mol of N-hydroxyethylpiperazine, 0.575mol of sodium 2-isethionate and 500mL of methanol into a 1000mL four-neck flask with a reflux tube, and carry out condensation reaction under full stirring; first react at 50°C for 2.0 Hours, then gradually increase the temperature and boil to reflux, and continue to react for 3.0 hours; then cool down to obtain a reaction mother liquor containing 4-hydroxyethylpiperazine sodium ethanesulfonate. Through high-performance liquid chromatography analysis, the calculated yield of sodium 4-hydroxyethylpiperazineethanesulfonate was 93.6%.

Embodiment 3

[0034] Add 0.5mol N-hydroxyethylpiperazine, 0.5mol 2-isethionic acid and 500mL acetone into a 1000mL four-neck flask with a reflux tube, then slowly add aqueous sodium hydroxide solution (mass concentration of 30%, containing 1.1mol sodium hydroxide); then react at 40°C for 2.0 hours, then gradually heat up and boil to reflux, and continue to react for 1.5 hours; then cool down to obtain the reaction mother liquor containing 4-hydroxyethylpiperazine ethanesulfonate . Through high-performance liquid chromatography analysis, the calculated yield of sodium 4-hydroxyethylpiperazineethanesulfonate was 89.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com