Method for preparing rubber-toughened PS foam material through extrusion of supercritical fluid

A supercritical fluid and rubber toughening technology, which is applied in the field of supercritical fluid extrusion to prepare rubber toughened PS foam materials, can solve the problems of complex process, non-continuous production, toxic and side effects, etc., and achieve simple process and improve mechanical properties. The effect of high performance and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

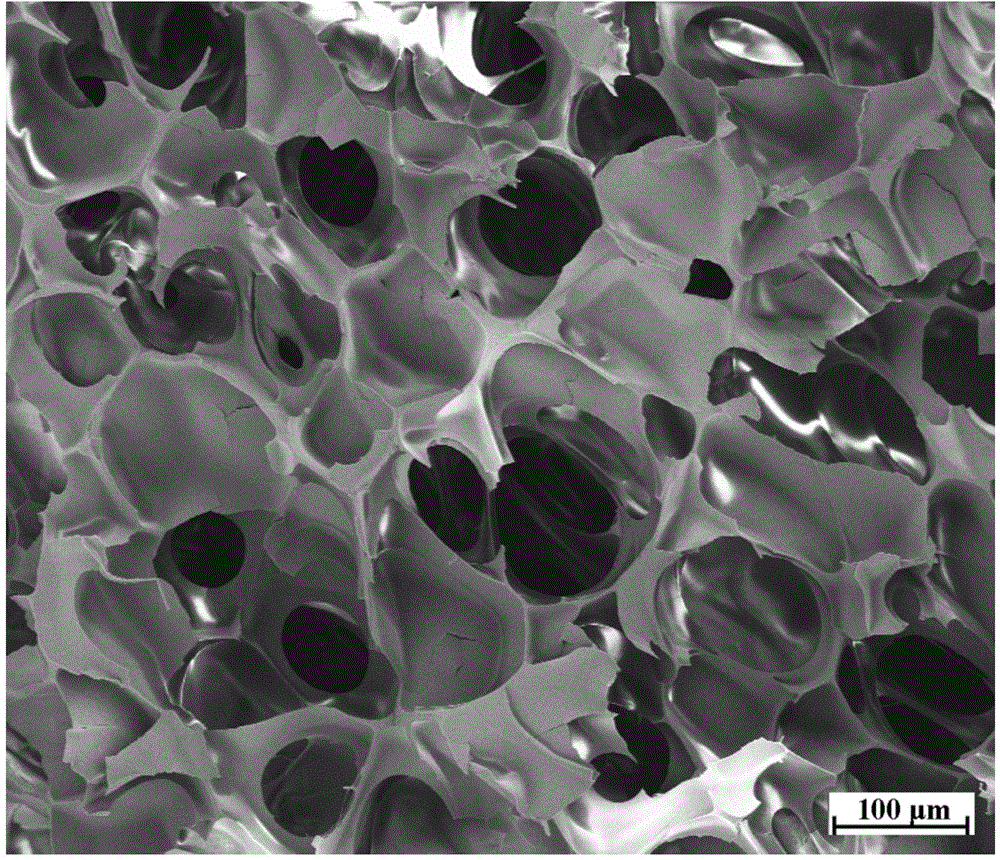

Embodiment 1

[0039] In this embodiment, a method for preparing rubber-toughened polystyrene foam material with supercritical fluid extrusion molding technology, the raw materials include polystyrene, SBS and nano-calcium carbonate; the weight of each raw material is in parts, polystyrene It is 80 parts, SBS is 20 parts, and nanometer calcium carbonate is 1 part.

[0040] The method for preparation comprises the following steps:

[0041] (1) polystyrene, SBS and nano-calcium carbonate are mixed according to the proportioning ratio, and are sent into the first extruder for melt blending and extruded granulation to obtain the polystyrene-based blend of the three-phase system;

[0042] The first extruder adopts a three-screw extruder, the blending temperature is 160-190°C, and the screw speed of the first extruder is 55 rpm;

[0043](2) Send the polystyrene-based blend into the second extruder for heating and melting, and at the same time inject the supercritical fluid into the plasticizing s...

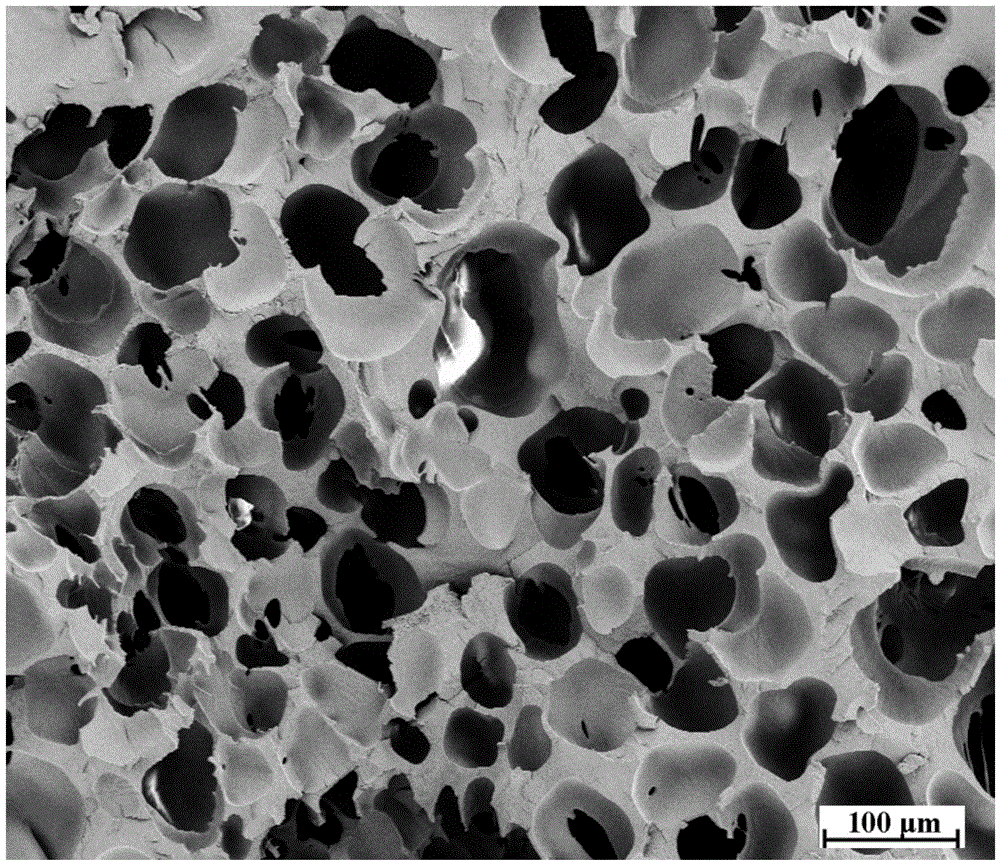

Embodiment 2

[0048] This embodiment is a method for preparing rubber-toughened polystyrene foam material by supercritical fluid extrusion molding technology. The raw materials include polystyrene, SBS and nano-calcium carbonate; wherein, the weight of each raw material is in parts, poly Styrene is 80 parts, SBS is 20 parts, and nano calcium carbonate is 3 parts.

[0049] The method for preparation comprises the following steps:

[0050] (1) polystyrene, SBS and nano-calcium carbonate are mixed according to the proportioning ratio, and are sent into the first extruder for melt blending and extruded granulation to obtain the polystyrene-based blend of the three-phase system;

[0051] The first extruder adopts a three-screw extruder and the blending temperature is 160-190°C, and the screw speed of the first extruder is 55 rpm;

[0052] (2) Send the polystyrene-based blend into the second extruder for heating and melting, and at the same time inject the supercritical fluid into the plasticizi...

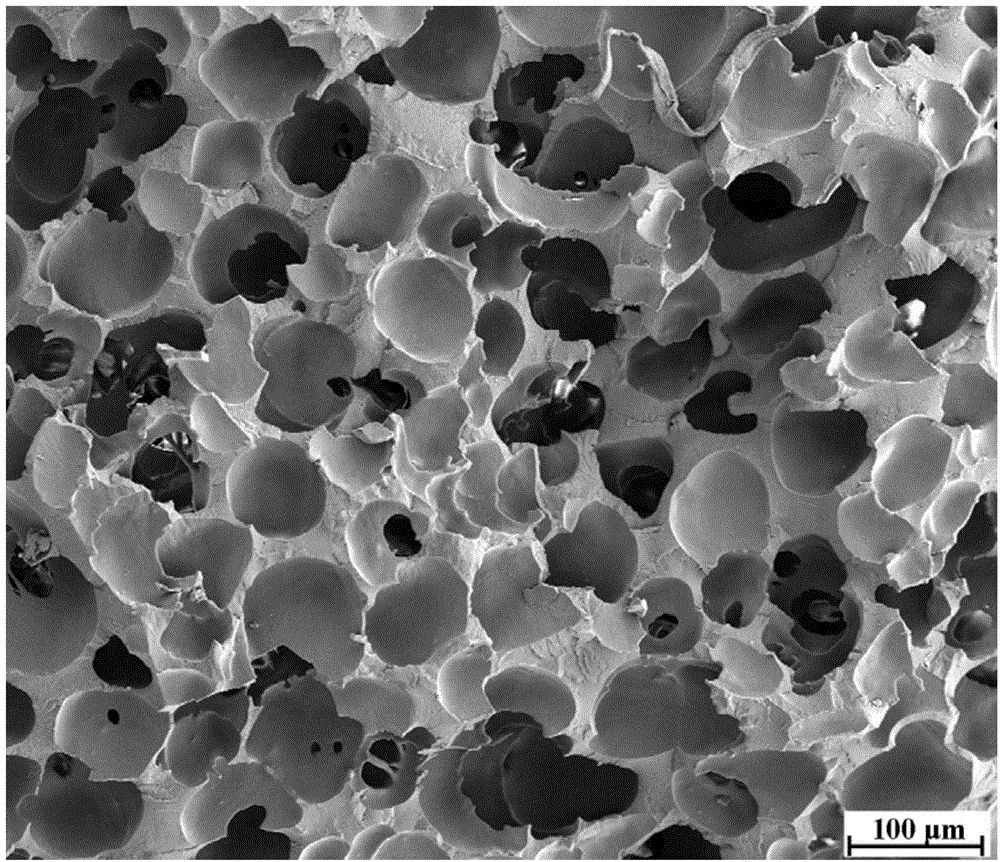

Embodiment 3

[0057] In this embodiment, a method for preparing rubber-toughened polystyrene foam material with supercritical fluid extrusion molding technology, the raw materials include polystyrene, SBS and nano-calcium carbonate; the weight of each raw material is in parts, polystyrene It is 80 parts, SBS is 20 parts, and nanometer calcium carbonate is 5 parts.

[0058] The method for preparation comprises the following steps:

[0059] (1) polystyrene, SBS and nano-calcium carbonate are mixed according to the proportioning ratio, and are sent into the first extruder for melt blending and extruded granulation to obtain the polystyrene-based blend of the three-phase system;

[0060] The first extruder adopts a three-screw extruder and the blending temperature is 160-190°C, and the screw speed of the first extruder is 55 rpm;

[0061] (2) Send the polystyrene-based blend into the second extruder for heating and melting, and at the same time inject the supercritical fluid into the plasticiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com