Shielding film with high heat-conducting coefficient

A technology with high thermal conductivity and coefficient, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve problems such as human health hazards, electromagnetic interference, abnormal work, etc., to improve utilization and improve stability , The effect of improving the service life of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

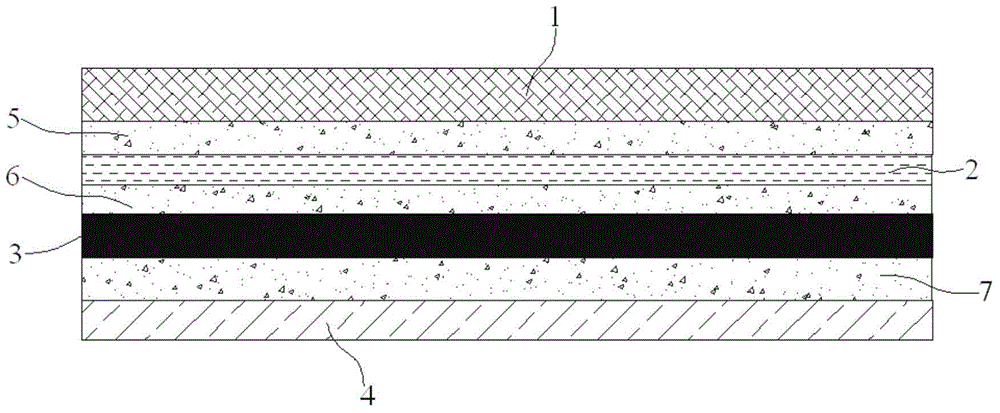

[0035] Embodiment 1: A shielding film with high thermal conductivity, including a PET insulating layer 1, a metal layer 2, a wave-absorbing layer 3 and a release material layer 4; a first adhesive layer is provided between the PET insulating layer 1 and the metal layer 2 layer 5, a second adhesive layer 6 is arranged between the metal layer 2 and the wave-absorbing layer 3, and a third adhesive layer 7 is arranged between the wave-absorbing layer 3 and the release material layer 4.

[0036] The components and contents of the absorbing layer 3 are as shown in Table 1:

[0037] Table 1

[0038] Example 1 Example 2 Example 3 Example 4 100 parts of absorbing powder 100 copies 100 copies 100 copies 100 copies 25~35 parts of butyl acrylate 25 copies 32 copies 30 copies 28 copies 12~15 parts of acrylic acid 12 copies 15 copies 14 copies 11 copies 20~35 parts of isooctyl acrylate 25 copies 22 copies 32 copies 35 co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com