Protective coating for thermoelectric material or thermoelectric device

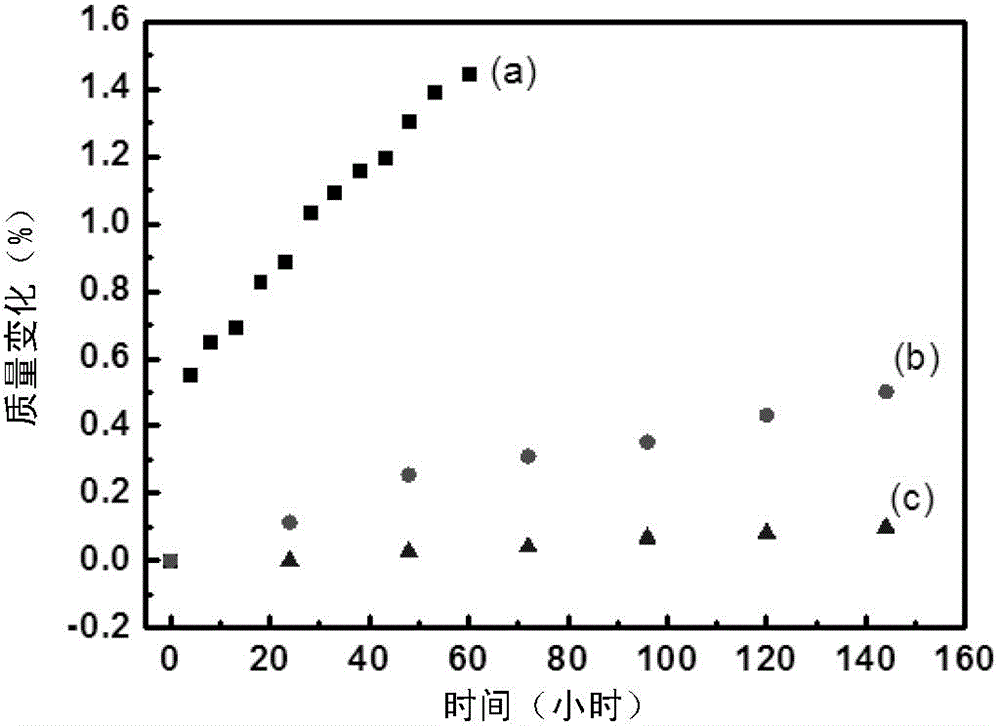

A technology of thermoelectric devices and thermoelectric materials, applied to thermoelectric devices, coatings, and layered products that only use the Peltier or Seebeck effect, can solve problems such as migration and coating microcracks, and achieve good compatibility and protection , the effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Take 15.00 g of methyltrimethoxysilane, 5.00 g of ethanol, and 5.01 g of water, adjust the pH to 3-4 with nitric acid, and bathe in oil at 60°C for 10 minutes to obtain component A. Glass powder (nominal chemical composition: 10 parts by weight of Na 2 O, 20 parts by weight of K 2 O, 10 parts by weight of TiO 2 , 10 parts by weight of BaO, 50 parts by weight of SiO 2 ) and silica sol at a ratio of 1:1 (parts by weight) to obtain component B. Blend B and A at a ratio of 1:5 (parts by weight), and stir evenly to obtain the desired slurry. Apply the slurry on the surface of the skutterudite-based thermoelectric material that has been sandblasted (the π-type device is polished to 400 mesh), ultrasonically cleaned, and dried at 80°C, and cured once in a vacuum drying oven at 100°C×2 hours at a low temperature to obtain a coating.

Embodiment 2

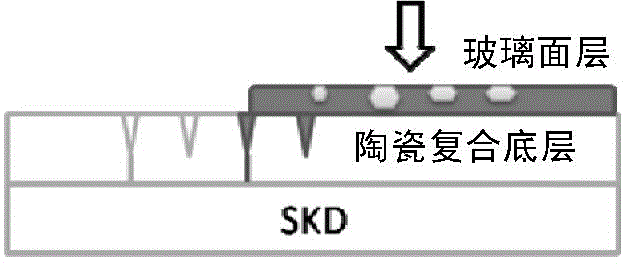

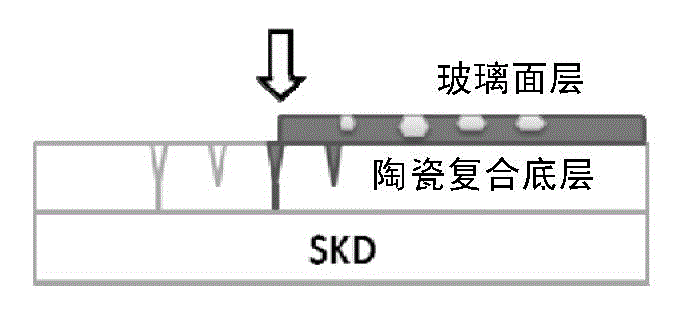

[0097] Preparation of ceramic composite bottom layer:

[0098] Preparation of Component A: Blend 13.61 grams of methyltrimethoxysilane with 5.4 grams of deionized water adjusted to pH 4-5 with nitric acid, and stir in a water bath at 60°C for 20 minutes to obtain Component A, which is Hydrolyzed polymer product of methyltrimethoxysilane;

[0099] The preparation of component B: with glass powder (nominal chemical composition: the Na of 10 parts by weight 2 O, 20 parts by weight of B 2 o 3 , 5 parts by weight of MgO, 10 parts by weight of TiO 2 , 10 parts by weight of ZnO, 45 parts by weight of SiO 2 ) 4.99 g and 5.09 g of silica sol are blended, adding an appropriate amount of dispersant and other additives, and ball milling at 206 rpm for 5 hours to obtain component B. Then add component A to component B, the mass ratio of component A to component B is 2.5:1. Ball mill at 150 rpm for 20 minutes to obtain organic-inorganic composite slurry. Coat it on the surface of the ...

Embodiment 3

[0104] Preparation of Component A: Mix 14.96 grams of methyltrimethoxysilane with 5.94 grams of deionized water adjusted to a pH value of 4-5 with nitric acid in a three-necked flask. Stir for 20 minutes to obtain Component A, which is a hydrolysis polymerization product of methyltrimethoxysilane;

[0105] The preparation of component B: with glass powder (nominal chemical composition: the Na of 10 parts by weight 2 O, 15 parts by weight of B 2 o 3 , 10 parts by weight of P 2 o 5 , 10 parts by weight of CaO, 55 parts by weight of SiO 2 ) 12.16 g was blended with the same quality of silica sol, added an appropriate amount of dispersant and other additives, and ball milled at 500 rpm for 7 hours and 20 minutes;

[0106] Add component A to component B, the mass ratio of component A to component B is 4:1, and ball mill at 500 rpm for 20 minutes to obtain a composite slurry. It is coated on the surface of the skutterudite-based thermoelectric material that has been sandblaste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com