Novel method of simply controlling particle sizes of ADC (azodicarbonamide) product

A new method and particle size technology, applied in the field of ADC foaming agent, can solve the problems of high energy consumption, increased energy consumption, unsatisfactory effect, etc., and achieve the effect of increasing the specific surface area and improving the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, the biurea is pulverized so that the median particle size (d50) reaches Aμm respectively, and then it is configured with water to form a 300L slurry with a solid content of 30%, which is pumped into a 500L enamel oxidation kettle, and the mass of biurea is added. 0.8% sodium bromide is used as a catalyst, the stirring is started, and the stirring speed is 72rpm. Chlorine gas was introduced into the reactor to carry out the oxidation reaction, and the reaction temperature was controlled to be 28°C. After the reaction is finished, filter and wash the filter cake through a suction filter tank until the pH of the filter cake is 7, and take a sample for analysis after drying.

Embodiment 2

[0024] Firstly, biurea is pulverized so that the median particle size (d50) reaches Aμm respectively, and then it is prepared with dilute acid to form 300L of slurry with a solid content of 30%, pumped into a 500L enamel oxidation kettle, and added biurea Sodium bromide with 0.8% urea mass was used as a catalyst, and the stirring was started at a stirring speed of 72 rpm. Hydrogen peroxide was added dropwise into the reactor to carry out the oxidation reaction, and the reaction temperature was controlled to be 40°C. After the reaction is finished, filter and wash the filter cake through a suction filter tank until the pH of the filter cake is 7, and take a sample for analysis after drying.

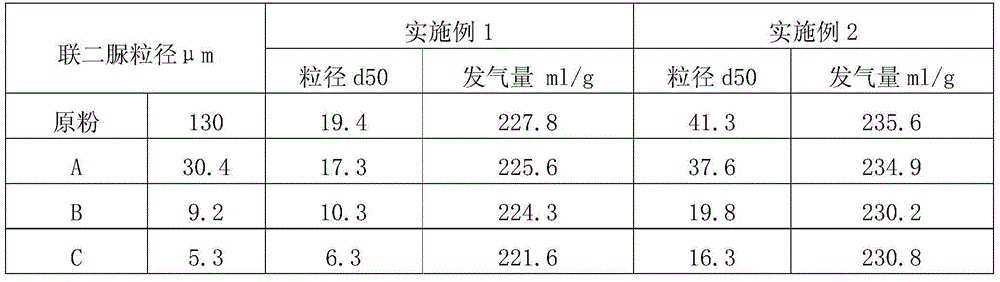

[0025] The analysis data is as follows:

[0026]

[0027] According to the analysis results, it is shown that with the reduction of the particle size of biurea, the particle size of the ADC produced by the chlorine oxidation method and the hydrogen peroxide oxidation method are all red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com