Waterborne antistatic coating as well as preparation method and application thereof

An antistatic and coating technology, which is applied in the direction of conductive coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of reduced conductivity, severe attenuation and limited conductivity, and achieve good mechanical properties and high strengthening and toughening effects Effects of abrasion resistance and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

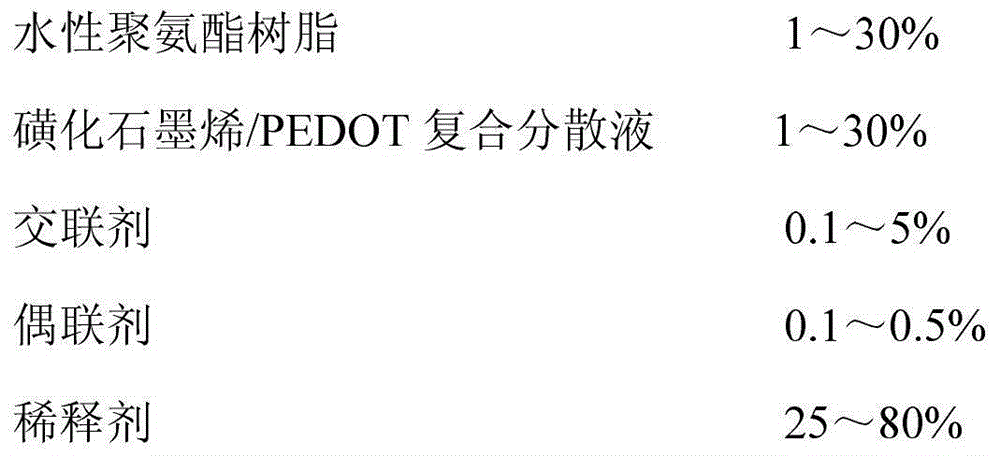

Method used

Image

Examples

preparation example Construction

[0035] In a more specific typical embodiment of the present invention, a kind of preparation method of waterborne antistatic coating can comprise the steps:

[0036] (1) Disperse sulfonated graphene, 3,4-ethylenedioxythiophene monomer (EDOT) and polyethylene glycol in deionized water at a temperature of 20-50°C, wherein sulfonated graphene: The mass ratio of EDOT is 0.1:1~1:0.1, the concentration of polyethylene glycol in the system is 0.001~1wt%, the pH value is adjusted to 0.5~4.5, high-speed stirring and mixing, and the rotation speed is 500~1000 rpm;

[0037] (2) While stirring at high speed, slowly add the mixed solution of oxidant and catalyst dropwise, the mass ratio of oxidant to EDOT is 0.5:1~2.5:1, the mass ratio of catalyst to EDOT is 0.001:1~0.1:1, and then Stir for 10-72 hours;

[0038] (3) The product is passed through dialysis or anion-cation exchange resin to remove impurity ions until no impurity ions are obviously detected in the product, and then diluted wi...

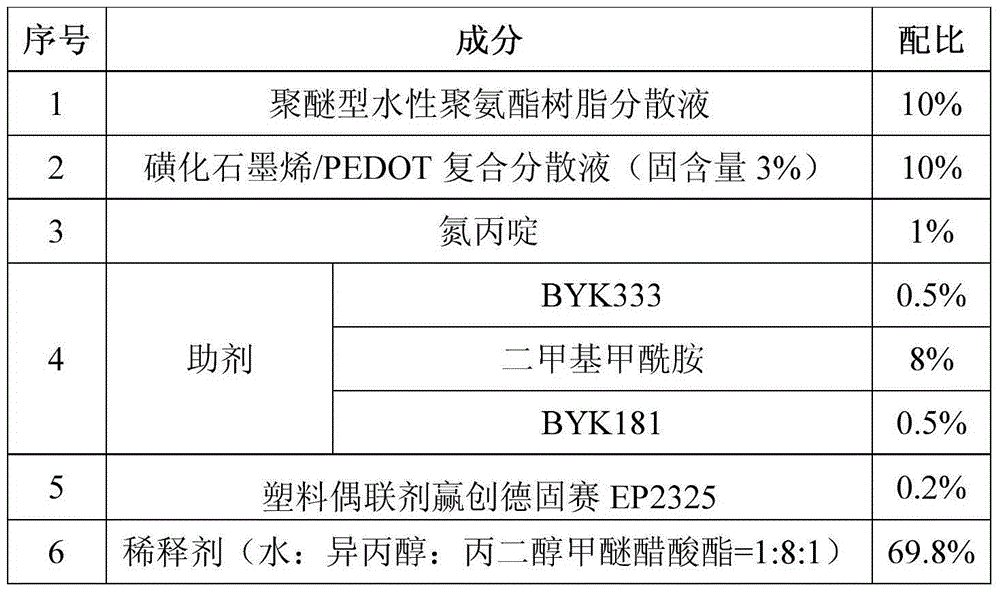

Embodiment 1

[0044] Weigh the raw materials according to the ingredient list, under 40 DEG C of water bath, sulfonated few-layer graphene (self-made with reference to Nano Lett., 2008,.8 (6): 1679-1682), 3,4-ethylenedioxythiophene monomer ( EDOT) and Polyethylene Glycol 400 are dispersed in 500ml deionized water, wherein the mass ratio of sulfonated few-layer graphene: EDOT is 1: 1.2, Polyethylene Glycol 400 concentration is 0.01wt%, its pH value is adjusted with hydrochloric acid to 1.5, stirring for 30 minutes at a speed of 800 rpm. Subsequently, slowly drop the mixed solution of sodium persulfate and ferric sulfate while stirring, the ratio of sodium persulfate to EDOT is 1:1, the mass ratio of ferric sulfate to EDOT is 0.01:1, and stir for 24 hours after the addition. The product was passed through a dialysis bag to remove impurity ions, and then diluted with deionized water to adjust the solid content of the solution to 3 wt%, to obtain a sulfonated graphene / PEDOT composite dispersion...

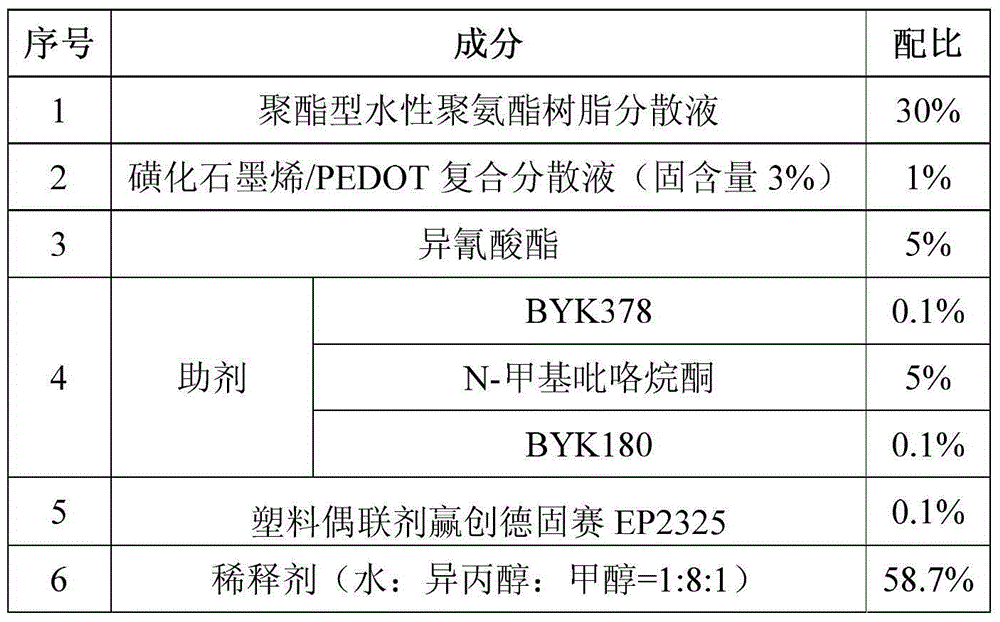

Embodiment 2

[0047] Embodiment 2: The difference between this embodiment and Example 1 is that the coating formula is different, and the coating formula is as follows (wt%):

[0048]

[0049] Referring to the scheme of Example 1, the antistatic PET material obtained by using the coating of this example has a light transmittance of 98% and a surface resistance of 10e9 ohms / square.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com