Low-soil-phase high-density calcium-resistant saturated salt water drilling fluid system

A high-density, soil-phase technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of water sensitivity of high salinity formations, reduce the compactness of mud cakes, and have great influence on rheology, and achieve resistance to water. Inferior soil has strong pollution ability, improved calcium resistance and low filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

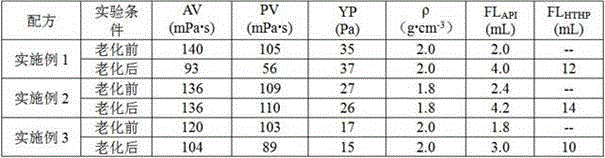

Embodiment 1

[0034] Weigh the components according to the amount of Example 1 in Table 1, and add the prepared drilling fluid sequentially under high-speed stirring (11000 r / min).

Embodiment 2

[0036] Weigh the components according to the amount of Example 2 in Table 1, and add the prepared drilling fluid in sequence under high-speed stirring (11000 r / min).

Embodiment 3

[0038] Weigh the components according to the amount of Example 3 in Table 1, and add the prepared drilling fluid in sequence under high-speed stirring (11000 r / min).

[0039] Table 1 Example 1-3 Low Soil Phase High Density Anti-Calcium Saturated Brine Drilling Fluid System Formulation Composition

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com