Corrosion inhibition type antisludging agent

A scale inhibitor and corrosion inhibition technology, applied in the field of scale inhibitors, can solve the problems of poor scale inhibition performance of scale inhibitors, and achieve the effects of increasing internal friction, improving scale inhibition efficiency, and excellent affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

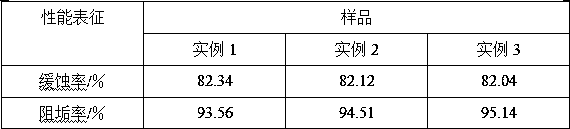

Examples

Embodiment Construction

[0017] In parts by weight, weigh 45-50 parts of deionized water, 10-15 parts of lignin, 10-15 parts of carboxymethyl starch and 25-30 parts of 15% ethanol solution in a three-necked flask, stir Mix and add dropwise 10% sodium hydroxide solution to adjust the pH to 8.5, and then stir in a water bath at 25-30°C for 20-25 minutes to obtain a mixed solution. Weigh 45-50 parts of the mixed solution, 3-5 parts of benzamide, 3-5 parts of sodium sulfite and 0.5-1.0 parts of ferric chloride are placed in an Erlenmeyer flask, stirred and mixed and adjusted to pH 5.5 with glacial acetic acid, left to cool to room temperature, and the cooled mixture is obtained by weight In terms of parts, weigh 45-50 parts of 10% ethanol solution by mass fraction, 6-8 parts of guar gum, 10-15 parts of cooling mixture, 6-8 parts of chloroacetic acid and 10-15 parts of propylene oxide in In a three-neck flask, adjust the pH to 9.0 with 10% sodium hydroxide solution by mass fraction, then heat in a water ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com