Coal briquette making and coal briquette coking production process by using coking wastes

A technology of production process and waste, which is applied in the field of briquette coking production process, can solve the problems of easy pollution of transport belt equipment, inability to process at the same time, injury of waste personnel, etc., achieve good economic benefits, environmental protection and energy saving benefits, and benefit the region Effects of Environmental Protection and Expansion of Coking Coal Resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

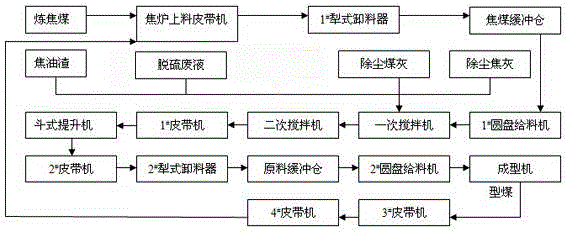

[0015] refer to figure 1 , using coking "waste" to make briquette and briquette coking production process, from the coke oven feeding belt conveyor with 1 # The plow unloader intercepts the coking coal, and after passing through the coking coal buffer bin, it is transferred by 1 # The disc feeder adds coking coal to the primary mixer, and the proportion of coking coal added accounts for 70% of the total raw materials. At the same time, 9% of tar residue, 6% of desulfurization waste liquid, 10% of dedusting coal ash, and 5% of dedusting The coke ash is added to the primary mixer, mixed and stirred by the primary mixer, the stirred material enters the secondary mixer for mixing, and the secondary stirred material passes through 1 # Belt conveyor, bucket elevator, 2 # belt conveyor, 2 # The plow unloader is sent into the raw material buffer bin, and the raw material buffer bin is discharged through 2 # The disc feeder is sent to the forming machine for forming, and the formed...

Embodiment 2

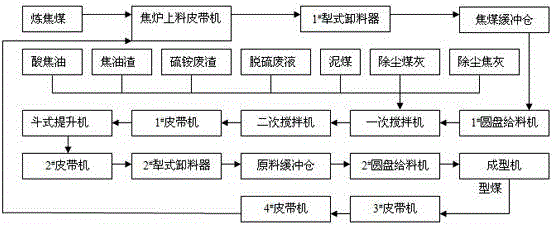

[0017] refer to figure 2 , using coking "waste" to make briquette and briquette coking production process, from the coke oven feeding belt conveyor with 1 # The plow unloader intercepts the coking coal, and after passing through the coking coal buffer bin, it is transferred by 1 # The disc feeder adds coking coal to the primary mixer, and the proportion of coking coal accounts for 55% of the total raw materials. At the same time, 4% of acid tar, 8% of tar residue, 3% of ammonium sulfate waste residue, and 5% of desulfurization waste Liquid, 9% dedusting coal ash, 6% dedusting coke, and 10% peat are added to the primary mixer, mixed and stirred by the primary mixer, and the mixed material enters the secondary mixer for stirring, and the secondary mixed material passes through 1 # Belt conveyor, bucket elevator, 2 # belt conveyor, 2 # The plow unloader is sent into the raw material buffer bin, and the raw material buffer bin is discharged through 2 # The disc feeder is sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com