Efficient wine cellaring device and method

A high-efficiency technology for cellaring wine, which is applied in the field of cellaring and high-efficiency cellaring wine, can solve the problems that the cellaring time cannot be significantly shortened, and achieve the effects of eliminating adverse reactions, low manufacturing costs, and the wine tastes mild and not over the top

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

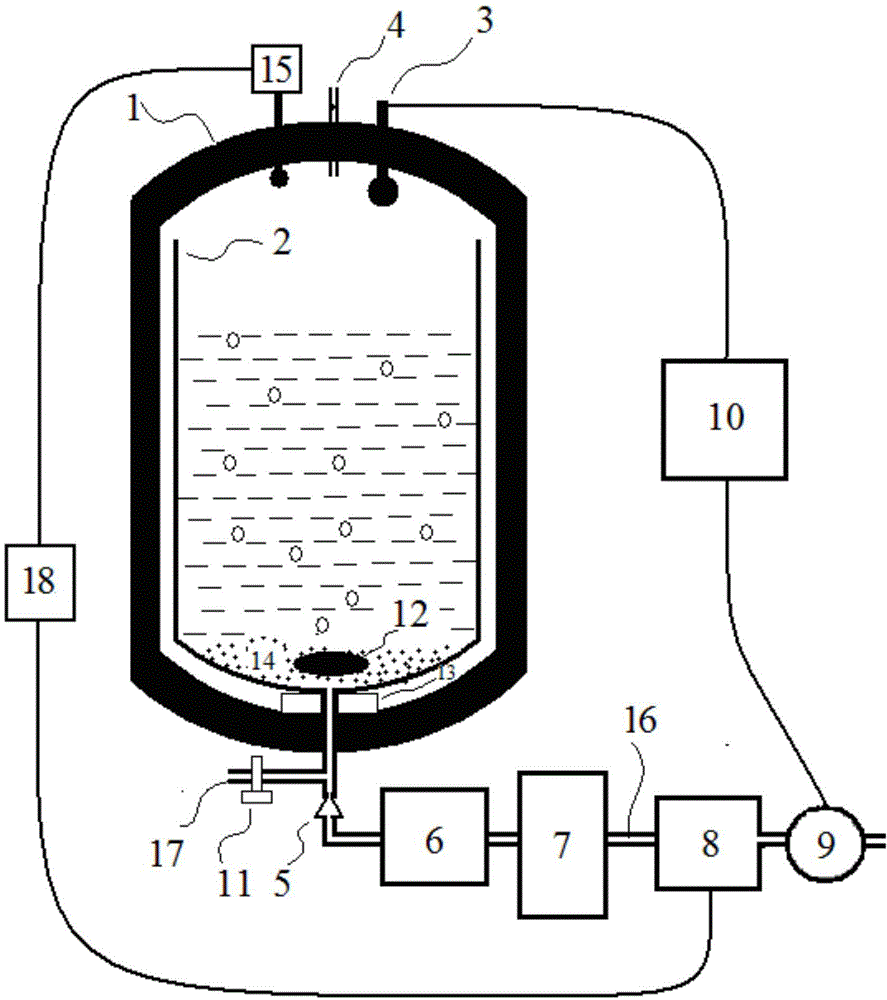

Method used

Image

Examples

Embodiment 1

[0030] A method for cellaring wine using the above-mentioned high-efficiency cellaring device for cellaring wine, comprising the steps of:

[0031] 1) The drinking water is electrolyzed by the electrolyzed water machine, so that the pH value of the alkaline electrolyzed water flowing out of the alkaline electrolyzed water outlet of the electrolyzed water machine is 9.0.

[0032] 2) Blending the original pulp of the fruit wine and the alkaline electrolyzed water according to the degree requirements to obtain a blended wine with a degree of 5 degrees.

[0033] 3) Open the liquid inlet valve, inject the blended wine into the ceramic tank, and close the liquid inlet valve;

[0034] 4) Turn on the high-pressure pump, air heater, negative ion generator and air purifier, the one-way air intake valve is automatically opened, and high-pressure negative ion air is introduced into the high-pressure tank, and the magnetic stirrer is turned on at the same time for stirring, and the rotor o...

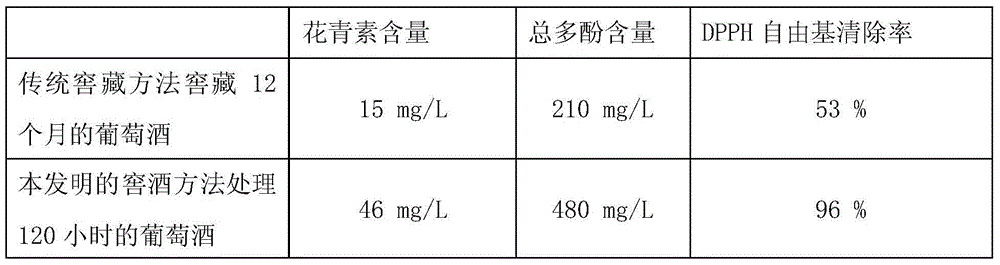

Embodiment 2

[0037] A method for cellaring wine using the above-mentioned high-efficiency cellaring device for cellaring wine, comprising the steps of:

[0038] 1) The drinking water is electrolyzed by the electrolyzed water machine, so that the pH value of the alkaline electrolyzed water flowing out of the alkaline electrolyzed water outlet of the electrolyzed water machine is 10.0.

[0039] 2) Blending the original pulp of the wine with the alkaline electrolyzed water according to the degree requirements to obtain a blended wine with a degree of 15 degrees.

[0040] 3) Open the liquid inlet valve, inject the blended wine into the ceramic tank, and close the liquid inlet valve;

[0041] 4) Turn on the high-pressure pump, air heater, negative ion generator and air purifier, the one-way air intake valve is automatically opened, and high-pressure negative ion air is introduced into the high-pressure tank, and the magnetic stirrer is turned on at the same time for stirring, and the rotor of the...

Embodiment 3

[0047] A method for cellaring wine using the above-mentioned high-efficiency cellaring device for cellaring wine, comprising the steps of:

[0048] 1) The drinking water is electrolyzed by the electrolyzed water machine, so that the pH value of the alkaline electrolyzed water flowing out of the alkaline electrolyzed water outlet of the electrolyzed water machine is 10.0.

[0049] 2) Blending the sorghum liquor protoplasm and alkaline electrolyzed water according to the degree requirements to obtain a blended wine with a degree of 55 degrees.

[0050] 3) Open the liquid inlet valve, inject the blended wine into the ceramic tank, and close the liquid inlet valve;

[0051] 4) Turn on the high-pressure pump, air heater, negative ion generator and air purifier, the one-way air intake valve is automatically opened, and high-pressure negative ion air is introduced into the high-pressure tank, and the magnetic stirrer is turned on at the same time for stirring, and the rotor of the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com