Cotton fabric anti-ultraviolet finishing application of ionic liquid metal complex and its finishing method and anti-ultraviolet cotton fabric

A technology of metal complexes and ionic liquids, used in textiles, papermaking, fiber processing, etc., can solve the problems of inability to achieve full-band UV shielding protection, the influence of fabric handle and mechanical strength, and the complex finishing process of fabrics. The effect of light absorption performance, protection performance expansion, and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

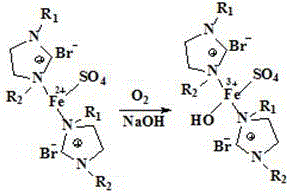

[0026] (1) Immerse 1.0-10 g of cotton fabric in an aqueous solution containing 0.5 g of ferrous sulfate, add 1.0 g of 1-butyl-3-methylimidazolium salt, and stir at 20°C for 10 hours;

[0027] (2) Add 1.0 g of sodium hydroxide to the above solution, react at 20°C for 10 hours, then wash the cotton fabric 3 times with clean water and dry it.

Embodiment 2

[0029] (1) Immerse 1.0-10 g of cotton fabric in an aqueous solution containing 1.0 g of ferrous sulfate, add 2.0 g of 1-butyl-3-ethylimidazolium salt, and stir at 20°C for 10 hours;

[0030] (2) Add 1.5g of sodium hydroxide to the above solution, react at 20°C for 10 hours, then wash the cotton fabric with clean water 3 times and dry it.

Embodiment 3

[0032] (1) Immerse 1.0-10 g of cotton fabric in an aqueous solution containing 2.0 g of ferrous sulfate, add 3.0 g of 1-butyl-3-propylimidazolium salt, and stir at 40°C for 5 hours;

[0033] (2) Add 2.0 g of sodium hydroxide to the above solution, react at 40°C for 5 hours, then wash the cotton fabric 3 times with clean water and dry it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com